Preparation, holes dug and posts concrete in

We already had a hedge around the property boundary but still needed a fence to make a safe enclosure for the dog and grandkids. We opted for a 900mm (3ft) high chain-link mesh and pipe fence so that eventually the hedge would grow through the fence and make it almost invisible. This entailed cutting one side of the hedge away to allow the fence to be positioned as close to the hedge trunks as possible.

This is how the fence was made…

Hedge cut back

- One side of the hedge was cut back as near as possible to the hedge trunks to make way for the fence.

- Having the fence line close to hedge trunks will allow the hedge to eventually grow through the mesh.

- The fence would then be buried in the hedge and practically invisible.

Post holes marked and dug

- A string line was put up to establish the fence line.

- The post hole positions were marked and dug to a depth of 600mm (2ft).

- The distance between each hole was a maximum of 3000mm (10ft). One or two had to be slightly repositioned along the fence line so as not to be over a major trunk root.

- The ground was firm and there was no frost line to worry about.

Posts lined up and concreted in

- The end posts and the corner posts (with their braces attached) were placed into their respective holes and hammered a few inches further into the ground until the posts were at the right height and also plumb.

- A string line was put up from corner post to corner post, to established a straight line and correct height for the intermediate posts.

- The intermediate posts were placed into the holes positioned plumb (upright) and not quite touching the string line. They were then hammered further into the ground until the posts were at the right height and able to stand up without support.

- Concrete was poured into the holes. The posts were again checked to ensure they were plumb before being left for a few days to allow the concrete to cure.

Posts and post bracing

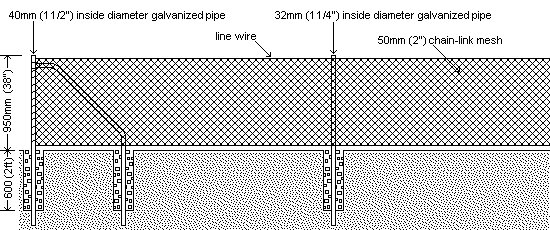

- The end and corner posts and braces were 40mm (1 1/2″) inside diameter galvanized pipe.

The intermediate posts were 32mm (1 1/4″) inside diameter galvanized pipe. - The posts were 1700mm (5′ 8″) long, allowing for 950mm (3′ 2″) above the ground, 600mm (2ft) into the post hole and another 150mm (6″) into the ground.

- The posts came cut to length and each post had two 3mm (1/8″) holes already drilled for the tie wire to go through and wrap around the line wire.

One hole was 25mm (1″) down from the top of the post and the second hole was 875mm (35″) below that, approximately 50mm (2″) above ground. - The corner posts and end posts had braces which were also 40mm (1 1/2″) inside diameter galvanized pipe.

- The braces were secured to the top part of the end posts with galvanized ‘T’ fittings and to the corner posts with adjustable corner fittings.

Wire strained and fastened

- The fence line wire was pulled taut between all end and/or corner posts using traditional wire strainers and then tied secure to the end/corner posts.

- For the home handyman there are other types of wire tightening tools available, such as the ratchet tightener below where the line wire is tied to each end of the tool and then tightened by turning the ratchet with a spanner.

- The disadvantage with this type of tool is that it must remain permanently in the fence.

- There were two fence line wires: one at the top of the fence about 25m (1″) down from the top of each post and one at the bottom of the fence about 50mm (2″) above the ground.

- The line wire was fixed to the intermediate posts with tie wire which was threaded through a pre-drilled hole in each post and then wrapped around the line wire.

- Each post had two pre-drilled holes: One for the top line wire and one for the bottom line wire.

One hole was 25mm (1″) down from the top of the post and the second hole was 875mm (35″) below that, approximately 50mm (2″) above ground.

Mesh laid out, stretched and tied

- The chain-link mesh size was 50mm (2″) and the wire size was 2.5mm. The height was 900mm (3ft).

- The chain-link mesh was rolled out along the fence line and secured to the first post with tie wire.

- The mesh was then stretched by hand to the next post and fixed to the post with tie wire and to the line wire with tie clips.

- This took two men: one to pull the mesh taut while the other fixed it in place with the tie wire and clips.

The finished fence

- Eventually the hedge will grow through the mesh and the fence will be practically invisible.