Contents

Introduction and Informative Stuff

Section 1.1 Introduction

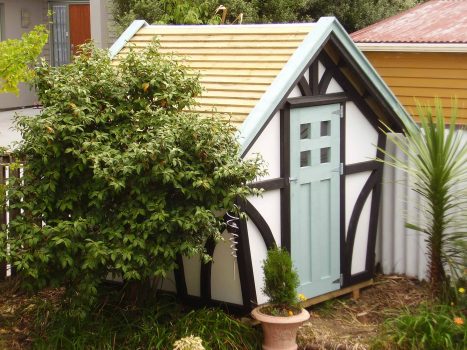

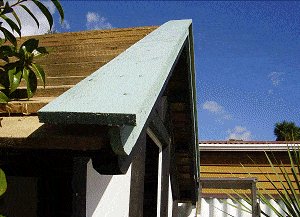

A garden shed does not have to be an eyesore, but a lot of them certainly are! People tend to buy or build a shed solely for its storage, or work capacity, without considering that a shed can also be a garden feature.

This Tudor-style shed certainly brightened up our garden.

The prose (written text) for this projects incorporates both imperial and metric measurements.

See more about that below, under the ‘Wood Sizes and the Measurements’ heading in section 1.3.

A bigger version of the Tudor-Style Shed can be seen here.

Section 1.2 Shed Description and Size

This shed has an appealing, fairy-tale Tudor look, with its sloping side walls and curved braces.

Whereas most wooden sheds consist of a frame, with a siding or wall cladding fixed on the outside, this shed has the cladding fixed on the inside. Sort of back-to-front from the ‘run of the mill’ shed.

The shed is roomier than the floor size would lead to believe, as the sloping side-walls give extra space, allowing shelves or work benches to be installed at mid-height, without encroaching too much over the floor area.

It is constructed mainly from 1 1/2″ x 3 1/2″ (90mm x 45mm) wood for the framing, 3/4″ (19mm) thick plywood for the floor and wall cladding, and 3/4″ x 6″ (150mm x 19mm) boards for the roof.

The inside floor size is 6ft (1800mm) wide x 6 1/2ft (1950mm) long.

The inside width gains another 22 inches” (550mm) at mid-height because of the sloping walls. Hence the 8×7 shed. The 8×7 refers to the wall size at mid-height.

The inside height at the highest point is around 8ft (2400mm).

The overall size of the shed (roof area) is 10ft (3000mm) x 8ft (2400m).

The overall height from the ground to the apex is 9ft (2700m).

Read below (section 1.4) to understand how the measurements are given throughout this project.

Section 1.3 Wood Sizes and the Measurements

The wood sizes referred to in this project are the actual sizes.

All measurements throughout this project are given in both Standard/Imperial inches, and Metric (mm).

The measurements are given first in inches, followed by millimeters (mm) in brackets ( ).

The inch sizes are not an exact match to the equivalent millimeter sizes.

For rounding-off purposes, we translate 1″ as being 25mm, which is not exact but near enough.

A shed built using the metric measurements will be approximately 1.6% smaller (hardly worth worrying about) than a shed built using the imperial (ft and in) measurements.

In other words, use one or the other but do not mix the two (for those of you who can work equally well with both standard and metric measurements) and you should have no problems as far as the dimensions go.

The imperial measurements are more suited to North America. The metric measurements are more suited to Australasia and other countries.

Section 1.4 The angles cut

Because of the sloping side-walls and the pitch of the roof, there will be a few varying angles to cope with.

Some of the angles may sound a bit daunting to figure out, but it is really quite easy once you know how.

And…

there is a section “getting the angles (part A few help notes for the Tudor Shed project, section 19.3) ” that explains how to make a template by pre-drawing all the angles on a square panel and then, with an adjustable T-bevel, simply transferring the angles to the members that require angle-cutting.

Plan Drawings and a Material List

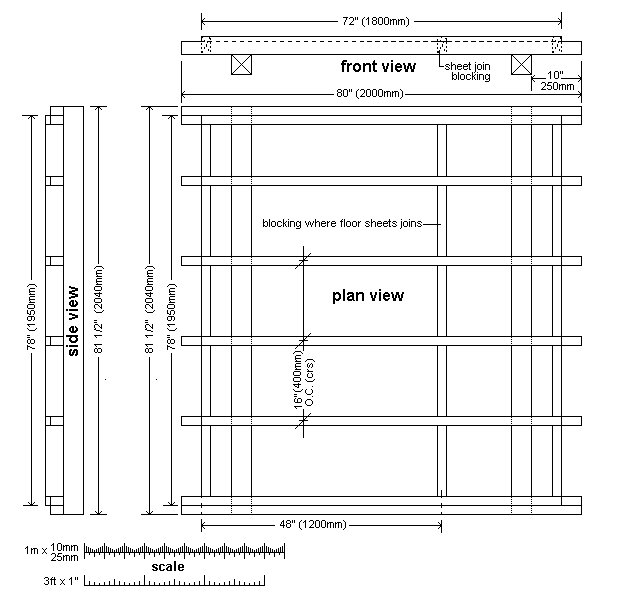

Section 2.1.1 Sub-Floor Plan

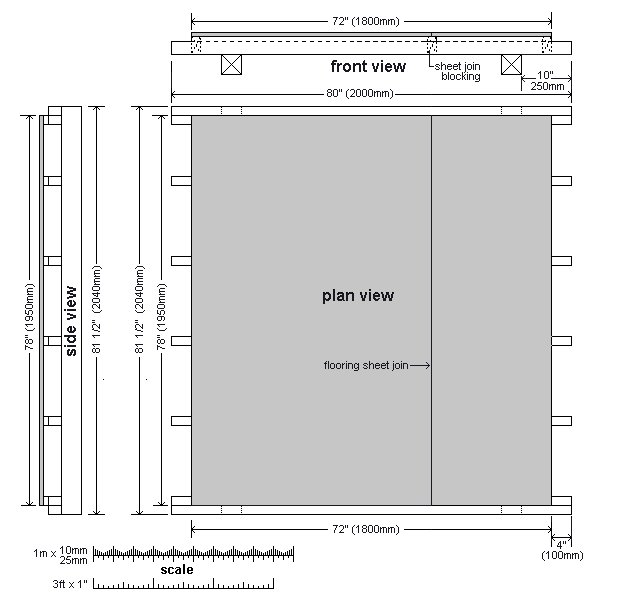

Section 2.1.2. Flooring Plan

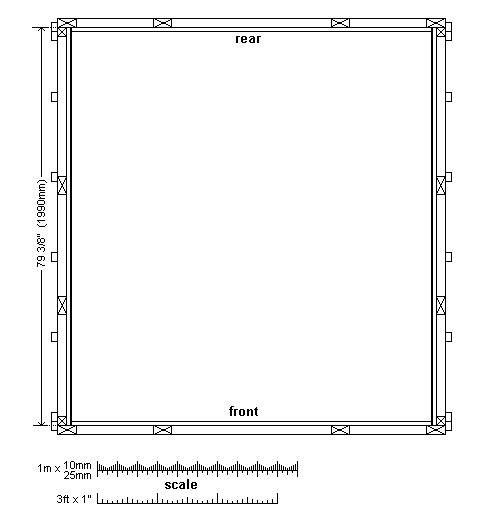

Section 2.1.3. Frame Layout Plan

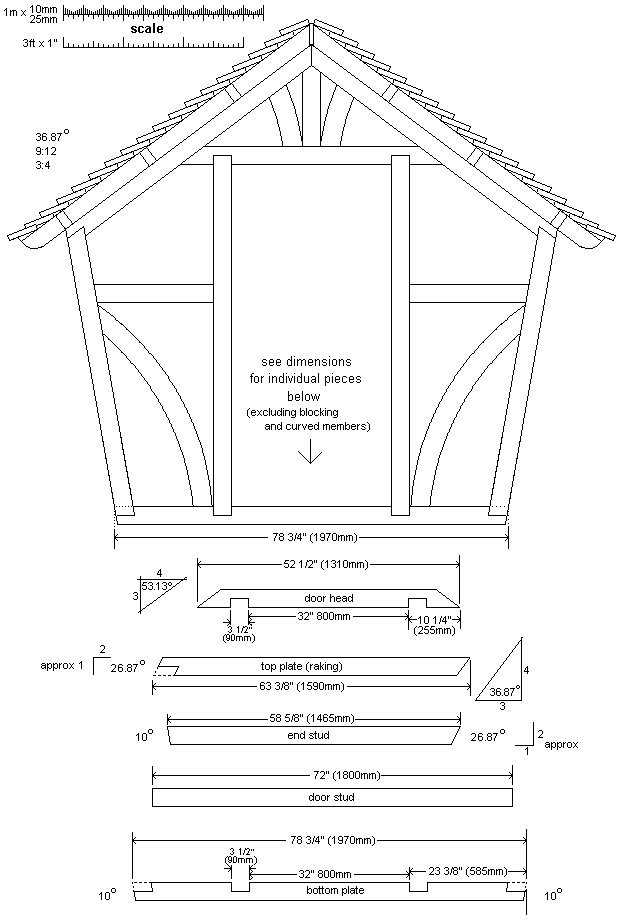

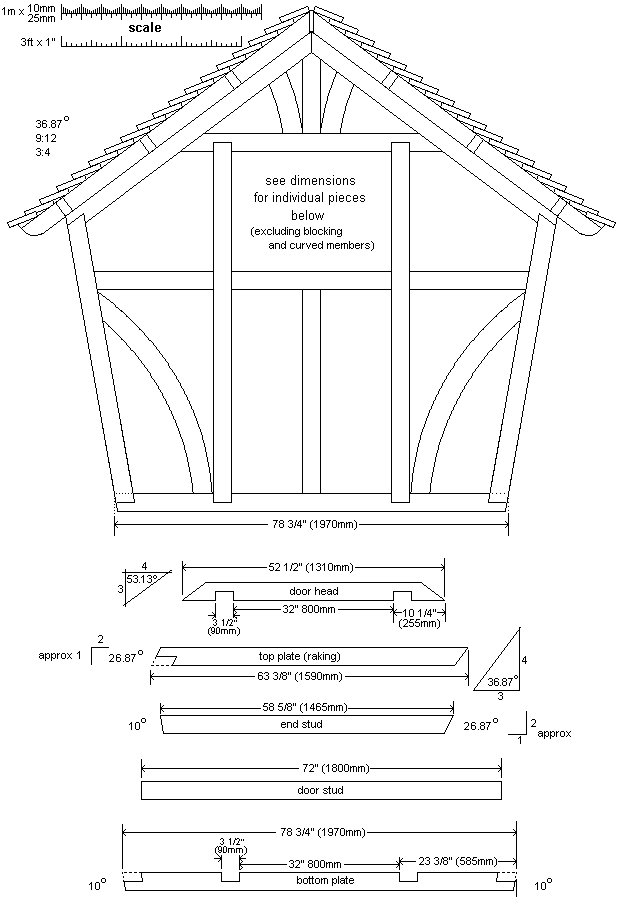

Section 2.1.4. Front Wall-Frame Plan

Section 2.1.5. Rear Wall-Frame Plan

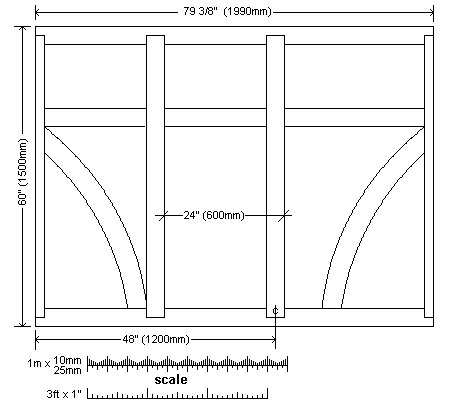

Section 2.1.6. Side Wall-Frame Plan

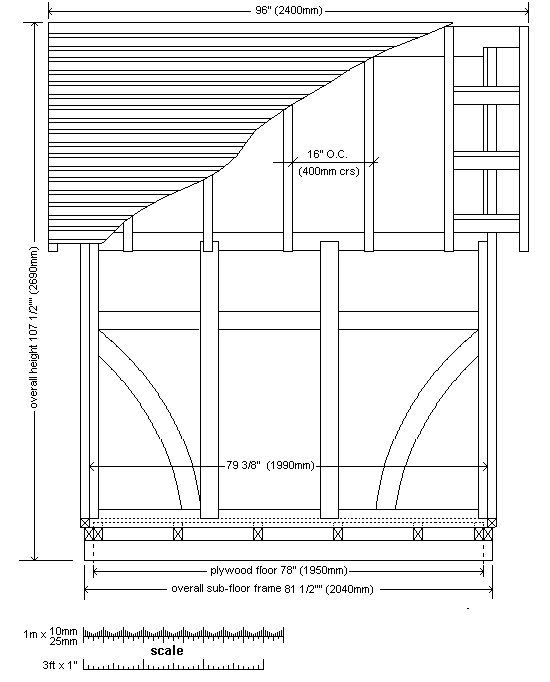

Section 2.1.7. Side Elevation Plan

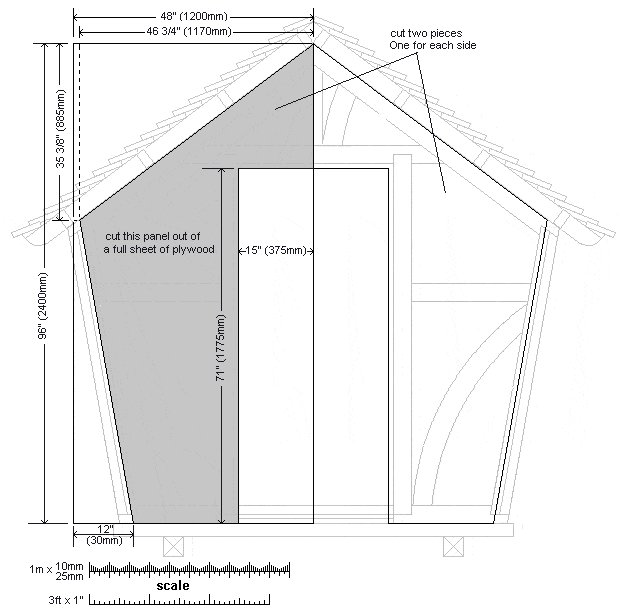

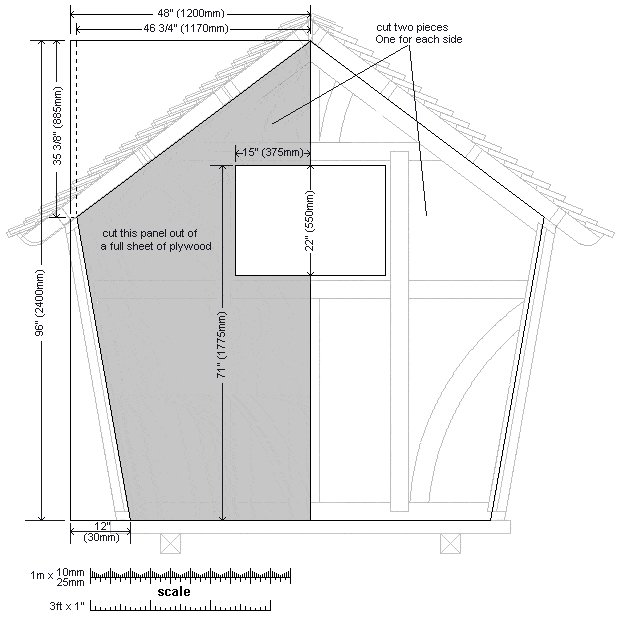

Section 2.1.8. Font Wall Sheet Detail

Section 2.1.9. Rear Wall Sheet Detail

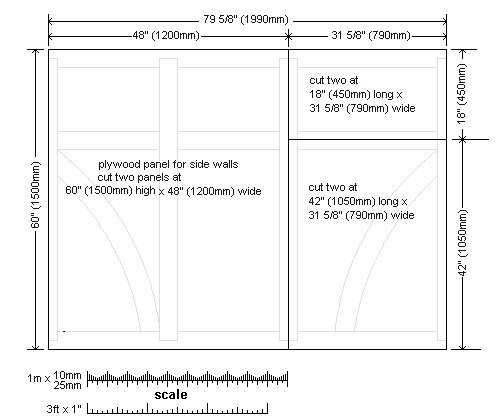

Section 2.1.10. Side Wall Sheet Detail

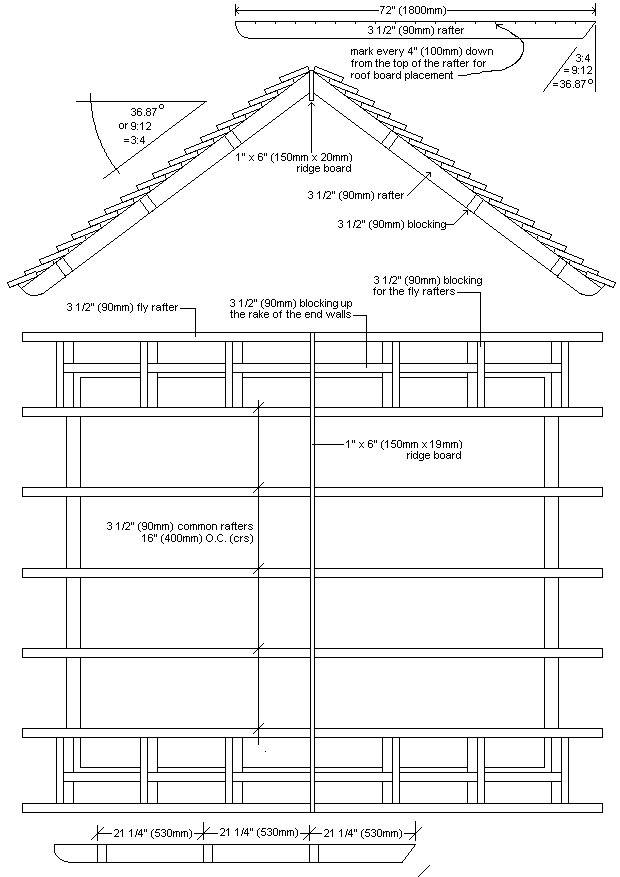

Section 2.1.11. Roof Plan

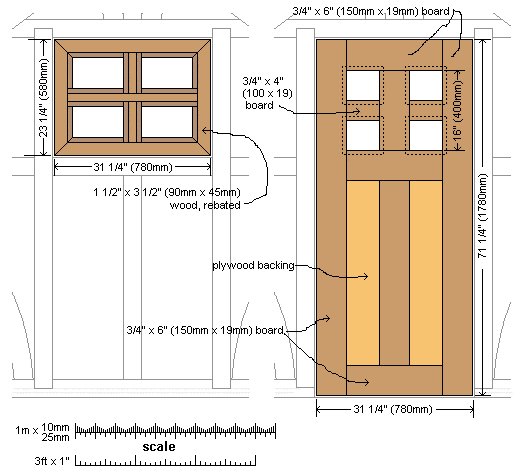

Section 2.1.12 Door and Window Plan

2.2. Material List

Some useful notes:

- Use treated wood, or wood suitable for outside use.

- Where only the total amounts are given, try to purchase in lengths as long as possible to minimize wastage.

- When cutting the frame members, cut the longest members first, then cut the shorter pieces from the off-cuts to avoid wastage.

- The total amounts do allow for a bit of wastage.

For this project you will need…

- Plywood:

- 9 of 4ft x 8ft (1200mm x 2400mm) sheets 3/4″ (19mm) thick.

- 1 1/2 x 9 1/2″ (240mm x 45mm) wood:

- 32ft (10 meters) for the curved decorative braces. This is optional but does look good.

- 4″ x 4″ (100mm x 100mm) wood:

- 2 lengths at 81 1/2″ (2040mm) long.

- 1 1/2″ x 3 1/2″ (90mm x 45mm) wood:

- 410ft (123 meters)

- 3/4″ x 6″ (150mm x 19mm) boards:

- 48 lengths at 96″ (2400mm)

- Acrylic sheet (plastic glass) 3mm (1/8″) thick:

- 4 pieces @ 8″ x 12″ (200mm x 300mm), 4 pieces @ 7″ x 8″ (175mm x 200mm).

Other bits and pieces you will need…

- An 8ft (2400mm) length of 2″ x 2″ (50mm x 50mm) galvanized angle for the ridge cap,

- 20 galvanized hurricane ties 8″ (200mm) long,

- some adhesive clear sealant for the windows,

- some wood glue,

- 3 of 6″ (150mm) T-hinges for the door,

- 2 of 3 1/2″ (90mm) butt hinges for the window,

- a latch for the door,

- a latch for the window,

- around 7 lb (3 kg) of 4″ (100mm) flathead galvanized nails,

- around 7 lb (3 kg) of 3″ (75mm) flathead galvanized nails,

- around 2 lb (1 kg) of 2 1/2″ (60mm) flathead galvanized nails,

- and some paint of your choice.

Making the floor

Section 3.1. Cutting the bearers and the floor joists

- Cut the two 4″ x 4″ (100mm x 100m) bearers at 81 1/2″ (2040mm) long.

- Cut eight 1 1/2″ x 3 1/2″ (90mm x 45mm) floor joists 80″ (2000mm) long.

- Rip (cut down lengthwise) a 1″ (25mm) strip off two of the joists. In other words, turn a couple of the 3 1/2″ (90mm) wide joists into 2 1/2″ (75mm) wide joists.

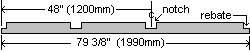

- The six common joists need to be rebated at both ends (see the pictures).

- Do this by first clamping them together on a couple of saw-horses.

- Make sure the ends are all in line and square, and that the tops are flush.

- Make a pencil-line across the top of the six joists, 4″ (100mm) in from each end. That defines the lengths of the rebates (the rebate area).

- Set the blade on a circular saw to a depth of 1″ (25mm) and make multiple cuts across the rebate areas, and then clean them out with a chisel.

- Ensure that the distance between the rebates at each end is 72″ (1800mm).

Section 3.2. Making the sub-floor

- Lay the two 4″ x 4″ (100mm x 100mm) floor bearers on a flat surface so that they are apart 60″ (1500mm) overall.

- Nail the two narrower (ripped) joists to a couple of the common joists.

- Use 3 1/2″ (90mm) galvanized flathead nails, 12 to each pair, staggering the nails along the length of the joist.

- That makes a pair of double joists, one pair to go each end of the bearers.

- Mark 10″ (250mm) in from the ends of both sets of double joists.

- That is the amount that the joists will overhang the bearers.

- Place the double joists on the bearers, one pair at each end.

- Ensure the bearers are 60″ (1500mm) apart overall and the joists overhang each side of the bearers by 10″ (250mm).

- Once in position, nail the double joists to the bearers.

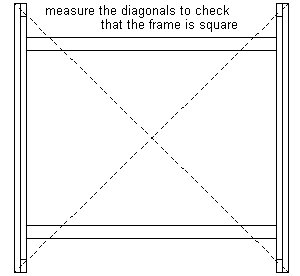

Section 3.3. Ensuring the floor frame is square

- Check to see that the work thus far is square.

- This can be done by measuring diagonally from corner to corner in one direction, and then by measuring diagonally in the opposite direction.

- If both measurements are the same, then the frame is square.

- If they are not the same, then the frame will need skewing a little until the diagonals are the same.

Section 3.4. Completing the sub-floor

- Run a taut string-line from the end of one joist, to the end of the other.

- Pack the string-line out from the joist ends with a nail.

- Lay the intermediate joists along the bearers at 16″ (400mm) O.C. (ctrs) and align the ends a nail’s breadth away from the string-line and then fix them to the bearers.

- Cut and fix three rows of blocks between the joists. A row along each side (beginning where the rebate ends) and also a row with its centers being 48″ (1200mm) from one side (where the rebate ends). It doesn’t matter which side, as that row is solely to support the plywood floor join.

- Check the diagonals again, as the sub-floor may have skewed slightly with all the hammering.

Section 3.5. Laying the floor

- Cut two pieces of 3/4″ (19mm) plywood. One at 78″ (1950mm) long x 48″ (1200mm) wide, and another at 78″ (1950mm) long x 24″ (600mm) wide.

- Lay the floor in place.

- Screw the floor sheets temporarily. The floor sheets may have to come off when the floor is moved to its final site, to allow the bearers to be packed, dug in, or whatever will be required to level and secure the sub-floor.

- However, if you are building the subfloor on site, and have it level and anchored, then by all means nail or screw the floor permanently.

- Meantime, the floor makes a good working surface to make up the wall frames.

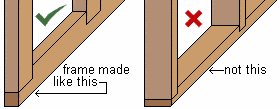

Making the front and rear wall frames

Section 4.1. Cutting the front and rear wall frame members

Note: The wall frames are made with all the members (studs, plates, etc.) being on their side, as opposed to their edge.

Guess you could say opposite to normal, as shown in the drawing.

That means that the finished wall-frames will be 1 1/2″ (45mm) thick, rather than the normal 3 1/2″ (90mm).

Begin by cutting the front and rear wall frame members as described below.

Begin by cutting the front and rear wall frame members as described below.- Some of the frame members will require an angle-cut at one or both ends.

- Need help working out the angles? See Getting the angles (part A few help notes for the Tudor Shed project, section 19.3)

- The front and rear walls are pretty much the same as each other, with the exception of the rear wall having a couple of additional members for the window.

- You can, therefore, cut most of the members for both walls at the same time.

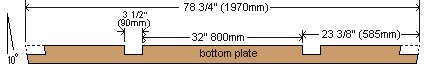

- Cut the two bottom plates 78 3/4″ (1970mm) long, with the ends angled in 10 degrees off square.

- You will need to cut a rebate at each end of the bottom plates to house the end studs, and also cut a couple of notches along the bottom plates to house the door/window studs.

- Clamp the two bottom plates together, so that you can cut the rebates and notches in both plates together.

- Use a block the same width as a stud, for a guide to mark the width of the rebates.

- Hold the block at each end on the face of the plates, flush with the angled end, and pencil-mark along the inside of the block.

- Then (with a square) continue the pencil-mark square across the top of the two plates.

- Next, measure out 16″ (400mm) each side from the center of the plates, to mark the distance between the door studs and the start of the door/window stud notch areas.

- Mark the width of the notch area using a block as a guide, in the same way as you marked the end rebates (as described above).

- Ensure (check with a square) that the pencil-lines across the top of the plates are square.

- Set the saw blade on a circular saw to a depth equal to half that of the wall-plate.

- Make multiple saw cuts across the notch area.

- Clean out the notches with a chisel.

- Then adjust the saw blade angle to 10 degrees and make multiple saw cuts across the rebate areas at each end of the plates.

- Check to see that the notches will house the studs by testing them with a block.

- Next the raking top plates.

- You will need to cut four raking top plates altogether, as there are two each side of both front and rear walls.

- So…

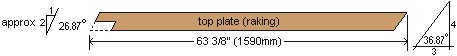

- cut 4 top plates at 63 3/8″ (1590mm) long, with a 36.87 degree angle at one end and a 26.87 degree angle at the other end.

- Need help working out the angles? See Getting the angles (part A few help notes for the Tudor Shed project, section 19.3)

- Of course, if you have an adjustable miter saw with the angles marked on it, it’s easy.

- Cut a rebate at the ‘26.87° angle end’ of the top plates.

- Pay attention to the drawing to ensure that the rebate is cut into the right edge of the plate.

- Clamp the four top plates together, and cut the rebate in the same manner as was done in the bottom plates.

- Next, cut four end studs 58 5/8″ long, with a 26.87 degree angle cut at one end and a 10 degree cut the other.

- Then cut four door/window studs 72″ (1800mm) long.

- Cut both the front door head and the rear window head 52 1/2″ (1310mm) long, with a 53.13 degree off square angle cut at each end.

- Need help working out the angles? See Getting the angles (part A few help notes for the Tudor Shed project, section 19.3)

- Mark where the notches go, but do not cut them just yet.

Also, do not cut any of the blocking just yet, as they will need to be measured in place once the rest of the front and rear wall frame members are nailed together.

Pictures in section 4.1 (above) from top to bottom.

Image 1) Marking a rebate on the plate.

Image 2) Multiple saw-cuts across the notch/rebate areas.

Image 3) The notches and rebates cleaned out.

Image 4) The members for the front and rear wall frames.

Section 4.2. Assembling the front and rear wall frames

- Lay the cut frame members in place on a flat surface and nail them together.

- Ensure the overall height is 96″ (2400mm). If not, pull the sides in or push them out as need be, to achieve that measurement.

- Then temporarily nail a brace across a frame to hold it in that position. Use a roof board as a temporary brace.

- Sit a door/window head in place, on top of the door/window studs. Check the door/window head is parallel with the bottom plate.

- Ensure the door/window studs are in line with the notch pencil-marks on each door/window head.

- Make a pencil-line across the tops of the door studs, in line with the underside of the door/window heads.

- Remove the door/window heads.

- The distance between the top of the door studs and the newly added pencil-line, will be the depth to cut the notches in the door/window heads.

- Set the depth of the saw blade accordingly.

- Clamp the two door/window heads together (one for the front wall and one for the rear wall).

- Cut out the notches by making multiple saw cuts across the marked notch area, and then clean them out with a chisel.

- Then fix the door/window heads in place.

- Measure, cut and fix the middle-row of horizontal blocks between the door studs and the end studs, with the top of the blocks being 48″ (1200mm) up from the bottom of the frame.

- The blocks will have one end cut at 10 degrees off square.

- The overall length of the blocks should be approximately 24″ (600mm).

- Cut four, two for the front wall and two for the back.

- Measure and cut the vertical block that sits on the top of the door/window head and fits under the apex.

- The top of this block has a point in the middle that angles back 36.87 degrees.

- The best way to cut this block, is to cut the point first on a block that is over length. Then hold the block up to the apex, mark the length, cut it, and fix it in place.

- The approximate length of the block should be around 16″ (400mm)

- Now measure, cut, and fix the two remaining window members (the sill and cripple stud) to the rear wall frame.

- There are still the curved brace members to cut and fix in place.

- Pictures in section 4.2 from top to bottom.

- Image 1) The front frame with a temporary brace to hold it in position.

- Image 2) Aligning the door/window head to mark the notches.

- Image 3) The top vertical block fixed in place under the apex.

- Image 4) Only the curved members to go.

Making the curved members

Section 5.1. Making the curved members

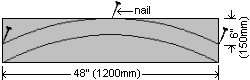

- Each curved member will need to be cut from a piece of 1 1/2″ x 9 1/2″ (240mm x 45mm) wood that is 48″ (1200mm) long.

- You will need eight curved members altogether, two at each corner.

- To cut the curves, a bandsaw or similar tool is ideal.

- However, it is possible to cut the curves with an ordinary circular saw, as explained in the section below.

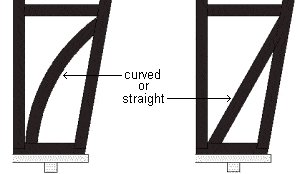

Or, don’t go with the curved members

- Alternatively, you can use straight pieces of 1 1/2″ x 3 1/2″ (90mm x 45mm) wood fixed diagonally.

- It will use less wood, be cheaper and still look good… just not as good as the curved stuff!

- OK, moving on.

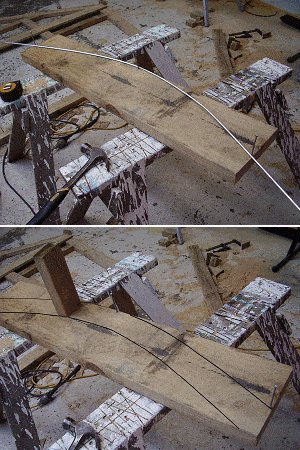

- If you still want to cut the curved members, first, mark out the curve.

- Bang three nails into a piece of 1 1/2″ x 9 1/2″ (240mm x 45mm) wood that is 48″ (1200mm) long, positioned as shown in the drawing below.

- Bend a length of rod (or anything that bends evenly) between the three nails, and pencil a curved line against the rod.

- That marks the outside edge of a curved member.

- Use a piece of wood the same width as a framing member, as a guide to mark the inside edge.

- Once you have cut the first curved member, use it as a pattern to mark and cut the rest.

Section 5.2. Cutting and fixing the curved members

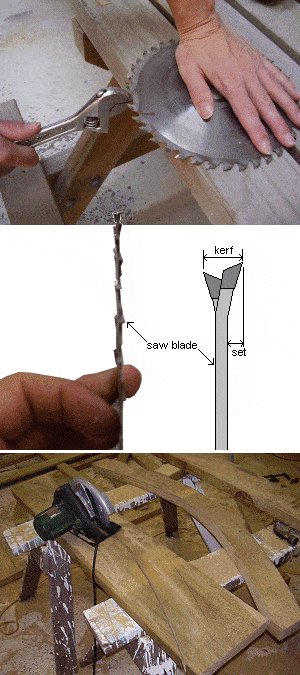

- Ideally, cut the curved members with a bandsaw, however if you do not have a bandsaw or are unable to get the use of one, then it is possible to cut the curves with an ordinary circular saw (after all, I did)

- but…

- you do need the right saw, and also you will probably need to tinker with the blade.

- The radius of this particular curve probably just falls within the boundaries that enable such a cut to be made.

- Not any old saw or any old blade will do it.

- You will need a saw with a bit of grunt, and with a blade size 7 1/4″ (185mm) diameter max.

- A blade that is any bigger will make it difficult to cut the curve.

- So in golfing terms, a bigger blade just won’t make the cut.

- You will also need to reset the teeth of the blade so that they bend out more, meaning the blade will make a wider cut, thus allowing the saw to turn easier.

- By default, the tips on tipped saw-blades point out in alternating directions, and the tooth ends on un-tipped saw-blades are bent outwards (set) in alternating directions.

- This is to obtain a kerf (cut) that is wider than the thickness of the blade plate.

- Our objective is to make the kerf (cut) wider by bending the teeth further in the direction that they are already leaning.

- You can bend the teeth easily enough, just by resting the blade flat on a workbench with the teeth overhanging. Then, grip a tooth with an adjustable spanner or a pair of pliers and exert a bit of downward pressure.

- It does not take much.

- Do every second tooth and then turn the blade over and do the same to every other tooth.

- Make sure you bend the teeth the right way: the teeth are already set slightly one way, and that is the way you must continue. Of course, once you have done this, the blade won’t be much good for anything else, and should be discarded.

- If the blade is set right, it should cut the curve as easy as cutting a straight line.

- If you have to struggle with the cut, then something’s not right.

- ENSURE SAFETY:

- Make sure the wood is clamped or secured firmly.

- Make sure you have stable footing and are fully in control of the saw. Wear safety glasses.

- That said, go and cut eight curved pieces, all of which are slightly over length at this stage.

- There will be two for each end of all four wall frames.

- There still needs to be four more smaller curved pieces cut for the top of the front and rear frames,

- but they can be cut from the off-cuts of the previously cut curves.

- They already have one curved edge cut, so they will only need to be cut on one side.

- They are also not as long and only four are needed altogether, two for the front wall and two for the rear wall.

- When all the curves have been cut (at this stage they are over-length), sit them in position on top of the wall frame, mark the ends of the curved pieces, cut them to length and fix them in place.

Making the side wall frames

Section 6.1. Cutting the side wall frame members

- Cut the side wall frame members as described below.

- Both the side walls are the same so you can cut the members for both at the same time.

- Cut six studs at 56 1/2″ (1410mm).

- Rip two of the studs in half to make up the four end studs, which are half the width of the common studs.

- Cut the four sidewall plates (a top and bottom plate for each side wall) at 79 5/8″ (1990mm) long. But, before you cut them, double-check the required length of the plates, just in case the plywood you are using is a different thickness or you made the floor platform at a slightly different length to the plan.

- Note: the exact lengths of the side wall plates should be the length of the floor platform PLUS two thickness of plywood, and all being according to plan, that should be 79 5/8″ (1990mm) long.

- Clamp the plates together, and mark out the notch and rebate positions as shown below.

- The notches are to house the intermediate common studs, and the rebates are to house the end narrow studs.

- Make multiple saw cuts across the notch and rebate areas, and then clean the notches/rebates with a chisel.

Section 6.2. Assembling the side wall frames

- Lay the side wall frame members in position on a flat surface.

- Nail the plates to the studs.

- Add a row of blocking 40″ (1000mm) up from the underside of the bottom plate to the underside of the blocking.

- Check to see if the wall is completely square.

- This can be done by measuring diagonally across the wall frame in one direction, and then by measuring the opposing diagonal.

- If both measurements are the same, then the wall-frame is square.

- If both measurements are not the same, then you will have to skew the frame a little until the diagonal measurements are the same.

- Once the frame is square, add a temporary diagonal brace to keep it square until you fix the curved braces to each side.

- To do this, lay the curved braces in position on top of the frame. Mark, cut, and fix them.

Marking the plywood wall panels

Section 7. Marking the plywood wall panels

- Although all the dimensions and measurements are given in the plan drawings for each and every plywood wall panel, it is probably best to mark the front and rear wall panels using the wall frames as a pattern, just in case they ended up being not quite to plan.

- This way, we know that the wall-panels will be the right size.

- OK,

- lay two full sheets of plywood together on an even surface.

- Lay the front frame on top of the plywood sheets, so that the join (between the two plywood sheets) is in the middle of the frame.

- Mark around the outside of the frame (onto the plywood) with a pencil and also mark the doorway.

- Take the frame off the plywood.

- Now mark another couple of lines, in 2 1/4″ (63mm) from the side lines, which will become the cutting line.

- Also make another pencil line an inch (25mm) in from the door line, all the way around. That will also become the cutting line.

Section 7.2. Cutting the plywood wall panels

- Lay the sheets on saw-horses or a cutting table in preparation for cutting.

- Set the blade on the circular saw to a depth of slightly more than the thickness of the plywood.

- If you are a dead-eye, then make the cuts free hand. I did, after all it is a shed! However, if you want perfectly straight cuts, then use a straight edge to guide the saw.

- Clamp the straight-edge to the plywood as a guide for the saw but make allowances for the distance between the blade and the side of the saw plate, to ensure the blade cuts along its intended line.

- When cutting the sheets, ensure the plywood is supported evenly on both sides of the cut, to avoid tearing should the off-cut piece fall.

- Do the same to the rear wall except of course there will be a pencil-mark around the window instead of a door, but the same principle applies.

- Then, out of two full sheets and an off-cut piece left over from the floor, cut the panels for the two side walls, which will be six panels in total, two at 60″ (1500mm) long by 48″ (1200mm) wide, two at 42″ (1050mm) long by 31 5/8″ (790mm) wide, and two at 18″ (450mm) long by 31 5/8″ (790mm) wide.

Refer to Section 2.1.6 Side-wall sheet plan for wall-sheet placement.

Cutting and preparing the roof frame

Section 8.1. Cutting the rafters

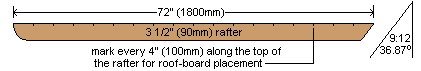

- Cut 14 rafters at 72″ (1800mm) long with an angle cut in at one end 36.87 degree off square.

- Need help working out the angles? See Getting the angles (part A few help notes for the Tudor Shed project, section 19.3)

- Stand the rafters on edge, stacked next to one-and-other, on a couple of saw-horses, with the bottoms of the rafters facing up.

- Make sure the ends are flush.

- Hold them firmly in place with a clamp or two.

- Pencil a line across the rafters, in 1/2″ (37mm) from the square-cut ends.

- Set the circular saw blade to a 45 degree angle and cut along the pencil line.

- Use a disk sander to round the 45 degree cuts.

- You can round them as little or as much as you like. It is solely for looks.

- With the clamps still on, turn the rafters over so the tops are facing up.

- Measure down from the top and make a mark every 4″ (100mm) along all the rafters.

- Those marks are for roof-board placement.

Section 8.2. Joining the fly rafters to the common rafters

- Now is as good a time as any to fix the fly rafters to the end common rafters.

- Cut 12 blocks 13 1/4″ (330mm) long.

- Stand 8 rafters side-by-side with their ends flush.

- Pencil-mark across the eight rafters every 21 1/4″ (530mm) down from the top. Three marks in all.

- Spread the rafters apart in pairs.

- Place three blocks in between each pair.

- Position the blocks on the top side of the marks on the rafters.

- Ensure everything is square and nail the rafters to the blocks, creating a sort of ladder effect.

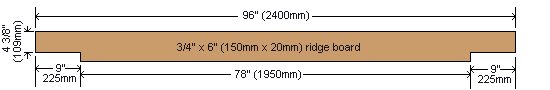

Section 8.3. Making the ridge board

- Cut a 3/4″ x 6″ (150mm x 19mm) ridge board at 96″ (2400mm) long. Cut a rebate at each end as shown in the drawing below.

Painting the wall frames and panels

Section 9.1. What to paint

- Now’s probably the best time to paint the frames and plywood cladding.

- You can slip-slap-slop paint all over the place without having to worry about all that tedious cutting-around where two contrasting colors meet.

- Prop the frames up against one-another, spread the plywood panels out, and go for it.

- I just used a charcoal fence paint for the frame and a gloss white for the plywood.

Section 9.2. What no to paint

- You don’t need to paint the insides of the frame and DON’T PAINT the tops of the rafters, as the tops of the rafters have already been marked for roof-board placement (section 8.1), and we don’t want to have to mark them all over again.

Fixing the wall panels to the frames

Section 10.1. Positioning the wall panels

- Note that the wall-panels for the front and rear frames do not sit flush with the sides of the frames.

- They are in from the sides 2 1/4″ (63mm), which is the thickness of a frame member plus the thickness of the plywood.

- So…

- When you lay the front and rear wall frames on a flat surface in readiness for the panels, pencil a line down each side of each frame, 2 1/4″ (63mm) in from the edge.

- That will give you a line to align the wall-panels to.

- In other words, the panels will be off-set 2 1/4″ (63mm) in from the side edges of the frame.

Section 10.2. Cutting away the door-fame bottom plate

- Cut out the bottom plate in the doorway and replace it with a temporary brace fixed to the underside of the plate, each side of the doorway, so the frame cannot spread out or close in until such time as it is ready to be securely fixed in place.

Section 10.3. Wall panel nailing detail

- Nail the sheets to the frame members with 2 1/2″ (60mm) galvanized flathead nails spaced at a maximum of 6″ (150mm).

Putting the floor in place

Section 11.1. Positioning the sub-floor

- Determine the position of the shed and then prepare the ground for the sub-floor.

- Make sure the ground where the floor bearers will sit is level and firm.

- Use a level or a water level to ensure the sub-floor is level.

- Also ensure the rest of the grade under the floor is lower than the underside of the floor joists.

- Lift the sub-floor in place.

- If the shed is in a sheltered or low wind zone, then no more action is required – continue laying the floor.

Section 11.2. Anchoring the sub-floor

- If you are concerned about strong winds and want the shed anchored to the ground, now is the time to do it.

- If need be, dig four fence post type holes, one near each end of both bearers. Place 4″ x 4″ (100mm x 100mm) posts into each of the holes and bolt them to the bearers.

- Fill the holes up with concrete.

- Of course, once you have done that, you will also have to secure the shed from the floor to the roof, otherwise the posts you just concreted in will be useless.

- One way to do that is to use metal galvanized strap, hurricane ties, or other fasteners, to tie the bearer to the floor joists, and fasteners to tie the floor joists to the bottom plates, and also fasteners (metal strap, hurricane ties etc) to fix the top plates to the roof rafters.

Section 11.3. Fixing the floor to the sub-floor

- You can now fix (nail or screw) the floor panels to the floor joists.

- Nail the floor sheets to the sub-floor members with 2 1/2″ (60mm) galvanized flathead nails (or 2″ (50mm) wood screws) spaced every 6″ (150mm) around the perimeter and along the join, and spaced every 8″ (1200mm) along the intermediate joists.

Standing the walls

Section 12.1. Standing the walls

- You will need a bit of a hand to stand the walls.

- The next part will take three people (just to make things easier) but only for a few minutes.

- Lift the rear wall and position it in place.

- Have one person balance the rear wall, while the other two people lift a side wall into position.

- Use a couple of clamps to hold the two walls together.

- You can now make the third person redundant. Send him home before he eats all the cake!

- Lift the other side wall into position and hold it in place with another couple of clamps. Likewise with the front wall.

Section 12.2. Fixing the walls together

- Nail at the corners through the front and rear wall studs into the side wall studs.

- Use 4″ (100mm) galvanized flathead nails. Four at each corner.

- Also nail the bottom plates to the sub-floor where possible.

Assembling the roof frame

Section 13.1. Putting up the ridge board

- The ridge board needs to be positioned so that the rebated parts at each end sit on top of the apex of the front and rear wall.

- This is best done by fixing a couple of galvanized hurricane ties to each end of the ridge board, in line with the beginning of the rebates.

- It is now an easy matter to fix the ridge board in place, by nailing through the hurricane ties into the inside-top of the front and rear walls.

Section 13.2. Fixing the fly rafters

- Fix the four made-up fly-rafter, block, and common-rafter combinations (the units that look a bit like a ladder) in place.

- This is best done by sitting one unit (fly-rafter, block, and common-rafter combinations) on one side of the rear wall top plate, so that the top of the rafters (fly and common) are up hard against the ridge board, (with the tops of the rafters being flush with the tops of the ridge beam, and the outside of the fly-rafter being flush with the end of the ridge beam).

- You may need somebody to help hold it in place while you nail.

- Nail through the ridge beam into the ends of the rafters. Do the same on the opposing side of the rear wall.

- Ensure the rafters are parallel with the top plate and then nail (toe nail, angle nail) through the blocking into the top plate to fix.

- Likewise with the front wall.

Section 13.3. Adding the common rafters

- Now add the rest of the common rafters evenly spread out along the ridge board. They should be approximately 16″ (400mm) O.C. (crs.)

- First nail them to the ridge board. Then run your eye along the ridge board and the side-wall top plates.

- Ensure they are straight.

- Fix the lower end of the common rafters to the side wall top plate by angle nailing (toe nailing) through the side of the rafters into the top plate.

- Just one nail at each meeting to hold.

- Then fix hurricane ties or similar fasteners to the rafters and the inside-top of the side walls.

Covering the roof

Section 14.1. Laying and fixing the roof boards

- The rafters have already been marked at every 4″ (100mm) along the top for roof board placement. That was done in section 8.1.

- Now clamp a board to the outside of a fly-rafter, running all the way up. Make the board at least the length of the rafter and protruding (sticking up) an inch or two above the fly rafter, creating a straight-edge to butt the ends of the roof boards up to.

- Begin laying and fixing the roof boards from the bottom and work your way up.

- Hold the first board with one end against the straight-edge and the top edge flush with the first row of marks on the rafters, which are 4″ (100mm) up from the ends.

- Nail the first board to the rafters using one 3″ (75mm) flathead galvanized nail at each rafter.

- For the first board only, nail it 3″ (75mm) down from the top of the board.

Note: Use 3″ (75mm) flathead galvanized nail if the boards you are using are 3/4″ (19mm) thick. If you use thicker boards, say 1″ (25mm) thick, then use 3 1/2″ (90mm) nails.

- Next the second board.

- Hold the second board with one end against the straight-edge, and the top edge flush with the second row of marks.

- The bottom of the second board should be overlapping the top of the first board by 2″ (50mm).

- Nail the board to the rafter using one 3″ (75mm) flathead galvanized nail 4 1/2″ (112mm) down from the top of the board at each rafter.

- The nail should go through both boards, the bottom of the top board and the top of the lower board.

- Likewise with the rest of the roof-boards working your way to the top.

Section 14.2. Fixing the ridge cap

- Fix a length of galvanized 2″ x 2″ (50mm x 50mm) angle flashing (ridge capping) along the top of the apex over the roof boards.

- Nail through the side of the flashing, through the roof boards into the top of the rafters.

A Tip or Two!

There are 12 plan drawings you can refer to at anytime. To see them go to page 2.

Section 14.3. About the barge cap and barge board

- The barge cap and the barge board is the trim that runs up the gable to cover the ends of the roof boards and the fly rafters.

- The barge caps sit flat on top of the roof boards, and overhangs the edge of the fly rafters by 2″ (50mm).

- The barge boards are fixed to the fly rafters directly under the barge caps.

- The barge cap is 3/4″ x 6″ (150mm x 19mm) board and the barge board is 3/4″ x 3″ (75mm x 19mm) board.

Note: Use spare roof boards for the barge cap and rip (cut down lengthwise) in half some roof boards to make up the barge boards.

Section 14.4. Cutting and fixing the barge cap and the barge board

- The barge capping is a piece of 3/4″ x 6″ (150mm x 19mm) board that runs up the rake of the roof, sitting flat over the ends of the roof boards.

- Cut four lengths of 3/4″ x 6″ (150mm x 19mm) at 76 3/8″ (1910mm) long, with the bottom cut square and the top cut with the circular saw blade set at a 36.87 degree angle off square.

- Need help working out the angles? See Getting the angles (A few help notes for the Tudor Shed project, section 19.3)

- Fix the barge cap in place with one edge overhanging the fly rafter by 2″ (50mm).

- The barge board is a piece of 3/4″ x 3″ (75mm x 19mm) board that goes under the barge cap and covers the fly rafter.

- Cut four lengths of 3/4″ x 3″ (75mm x 19mm) at 75 1/4″ (1880mm) long, with the bottom cut rounded and the top cut angled in 36.87 degrees off square.

- Fix them to the fly rafters directly underneath the barge capping.

- Note: Rip some roof boards in half (cut down lengthwise) to make the barge boards.

Making the door

Section 15.1. Determining the door size

- Measure the door opening in the wall (called the rough opening).

- Deduct 3/4″ (19mm) off the height and the width to get the door size.

- For example: The door opening in the frame is (or should be) 72″ (1800mm) high x 32″ (800mm) wide.

- Therefore, make the actual door 71 1/4″ (1780mm) high x 31 1/4″ (780mm) wide.

- There should be a maximum 3/8″ (10mm) gap all around the door.

Note: You can work with a 1/4″ (6mm) gap all around. I just prefer a bigger gap around shed doors.

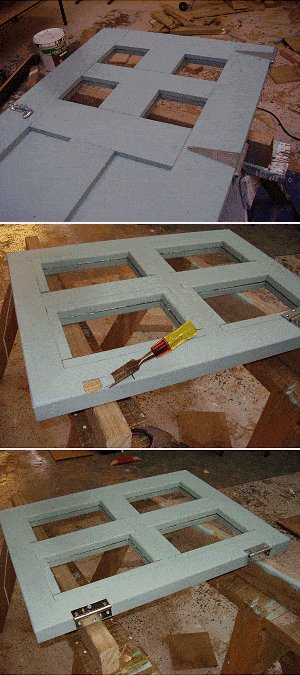

Section 15.2. Cutting and preparing the door pieces

- Cut a piece of 3/4″ (19mm) plywood 71 1/4″ (1780mm) high x 31 1/4″ (780mm) wide and lay it on a flat surface.

- Cut two 3/4″ x 6″ (150mm x 19mm) boards at 71 1/4″ (1780mm) long and place them on the plywood, one each side.

- Measure and cut the three 3/4″ x 6″ (150mm x 19mm) horizontal rails and place them on the plywood in position.

- Refer to the plan drawing in section 2.1.12 for positioning

- Do not fix permanently at this stage.

- Measure, cut, and fit in place, the window cross pieces out of 3/4″ x 4″ (100mm x 19mm) board.

- Note: Rip (cut down lengthwise) the window cross pieces from a spare roof board.

- Mark the window openings on the plywood. Also mark where the other pieces go, so you know where to apply the glue.

- Remove all the pieces off the plywood.

- Mark 3/4″ (19mm) out from the previously marked window opening, all the way around, and cut out along that mark.

Section 15.3. Assembling and fixing the door pieces

- Apply ample glue on the plywood areas to be covered.

- Place all the other pieces back into position on the plywood and hold them in place with clamps.

- Fix with either screws or nails.

- If you use screws, make sure that they are long enough to almost go through the total thickness of the wood.

- If you use nails (as was used in this project) then use galvanized flathead nails that are a bit longer than the total thickness of the wood. Nail through the front of the door, and bend the ends of the nails over at the back of the door.

Section 15.4. Making the glass stop for the door window

- Note: The glass stop is s strip of wood that covers the edge of a window pane and holds it in.

- Rip a length of wood 3/4″ (19mm) wide and at least 11ft (3300mm) long from a spare roof board for the glass stop.

Section 15.5. Painting the door

- Paint the door and the glass stop. I used a water-based paint and the color was called “duck-egg blue”.

Section 15.6. Fitting the window panes

- Measure the window pane areas in the door window and have 1/8″ (3mm) thick clear acrylic (plastic) or glass panes cut to fit loosely into each area.

- According to the plans you will need four panes 7″ x 8″ (175mm x 200mm) but check just in case.

- Place them in the appropriate openings.

- Cut the glass stop to go around the perimeter of the window pane, and angle nail (toe nail) with 1/2″ (40mm) galvanized nails through the glass stop into the surrounding window frame.

- Once the glass stop is fixed around each window pane, run a thin bead of clear sealant around the sides and bottom of each pane.

A Tip or Two!

There are 12 plan drawings you can refer to at anytime.

To see them go to page 2.

Need help working out angles? See Getting the angles (part A few help notes for the Tudor Shed project, section 19.3)

Making the window

Section 16.1. Determining the window sash size

- Note: A window sash is the moving segment of the window, consisting of two side stiles (vertical members), a top rail (horizontal member) and a bottom rail (horizontal member) and muntins.

- To determine the sash size, measure the window opening in the wall frame (called the rough opening).

- Deduct 3/4″ (19mm) off the height and the width to get the window sash size.

- For example: The window opening in the frame is (or should be) 24″ (600mm) high x 32″ (800mm) wide.

Therefore, make the actual window size 23 1/4″ (580mm) high x 31 1/4″ (780mm) wide.

So there should be a maximum 3/8″ (10mm) gap all around the door. - Note: You can work with a 1/4″ (6mm) gap all around. I just prefer a bigger gap for sheds.

Section 16.2. Making the window sash

- Use 1 1/2″ x 3 1/2″ (90mm x 45mm) wood.

- Take a length 10ft (3m) long and make a rebate 1″ x 1″ (25mm x 25mm) down one edge.

- Take a length 48″ (1200mm) long and make a rebate 1″ x 1″ (25mm x 25mm) down two adjacent edges.

- The rebates can be cut by first marking the rebate lines along the wood, and then setting the blade on your circular saw to a depth of 1″ (25mm) and cutting down the lines.

- Save the off-cut piece, as that can be used for the glass stop to hold the acrylic or glass window panes in place.

- Once rebated:

- Using the wood with a single rebate, cut four pieces, all with a 45 degree angle at both ends.

- Make two pieces 31 1/4″ (780mm) long and two pieces 23 1/4″ (580mm) long.

- Clamp the pieces side-by-side together (flush) and mark and cut a notch in the middle.

- Make the notch 1 1/2″ x 3 1/2″ (90mm x 45mm) wide (which is the width of the window cross members) and as deep as the rebate.

- Then glue and screw the four pieces together at the corners making a “picture frame”.

- Measure across the middle of the window between the side notches and cut the horizontal muntin bar (horizontal middle rail) to length.

- Then make a notch in the middle each side of the horizontal muntin bar to house the vertical muntin bar (vertical middle rail).

- Fit, glue, and screw the horizontal muntin bar in place.

- Then measure and cut the two vertical muntin bars (one top and one bottom of the horizontal muntin).

- Fit, glue, and screw the vertical muntin bars in place.

- Fix a corner metal angle to the outside of each corner.

Section 16.3. Painting the window

- When the glue has dried, sand the sash ready for painting.

- Paint the window sash and the beading.

- I used a water-based paint and the color was called “duck-egg blue”.

Section 16.4. Fitting in the window panes

- Measure the window areas (four altogether) and have 1/8″ (3mm) thick clear acrylic (plastic) or glass panes cut to fit loosely into each area.

- According to the plans you will need four panes 8″ x 12″ (200mm x 300mm) for the window but check just in case.

- Place them in the window holes.

- Cut the glass stop to go around the perimeter of the panes and then angle nail (toe nail) through the glass stop into the surrounding sash frame.

- Once the glass stop is fixed around each window area, run a thin bead of clear sealant around the sides and bottom of each pane.

Installing the door and the window

Section 17.1 Fitting the hinges

- The door opens out, and the widow opens up.

- Therefore, hinges need to be fixed to the side stile (vertical side member) of the door, and to the top rail on the window sash.

- The door uses three 6″ (150mm) T-hinges and the window uses two 3 1/2″ (90mm) butt-hinges.

- Begin fitting the hinges by laying the door and the window on saw-horses or other work platform.

- Screw three 6″ (150mm) T-hinges to the side stile of the door, one in line with the top rail, one in line with the middle rail and one in line with the bottom rail.

- Do you want the door opening out to the left or to the right? That will determine what side of the door you fix the hinges to.

- The window will need two 3 1/2″ (90mm) butt-hinges screwed to the top rail but they will need to be sunk 5/16″ (5mm) into the rail.

- Why?

- Because the window sash is the same thickness as the surrounding frame. If the hinges were not checked into the top rail, then the sash would bind or jam against the stop when being opened or closed.

- By sinking the hinge into the rail, it brings the top of the sash away from the stop, thus eliminating the possibility of binding or jamming.

- Once the hinges are on, the door and window are ready to hang in place.

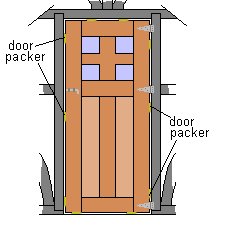

Section 17.2. Hanging the door and the window

- Place the door in the door opening and pack the sides, top, and bottom (between the door and the opening) so there is even gap all the way around.

- Then screw the hinges to the surrounding frame.

- Take out the packers, align and fix the bolt catch.

- Hang the window following the same procedure.

The drip caps

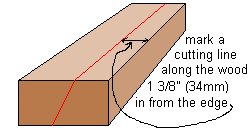

Section 18.1. Making and fixing the drip caps

- A drip cap is a horizontal piece of wood that is fixed above the door and window to deflect any water from running inside.

- This project requires two drip caps. One to go above the door, and one to go above the window.

- Both drip caps can be shaped from a piece of 1 1/2″ x 3 1/2″ (90mm x 45mm) wood that is 36″ (900mm) long.

- Make a pencil line down the length of a piece of 1 1/2″ x 3 1/2″ (90mm x 45mm) wood that is 36″ (900mm) long.

- See the drawing below for the dimensions.

- Set the angle of the blade on a circular saw (or bench saw) to 26.87 degrees off square.

- Need help working out the angles? See Getting the angles (part A few help notes for the Tudor Shed project, section 19.3)

- Then rip (cut down lengthwise) along the pencil-line.

- That will make two drip caps. One for above the window and one for above the door.

- Now a bit of paint.

- When the paint is dry, fix one above the door and one above the window and as low as possible so as not to get in the way of the door or window opening or closing.

A few help notes for the Tudor Shed project

Section 19.1. Help sources – Where to find help

There are a few help initiatives for the Tudor Shed Project.

1.) There are help notes on this page. Help notes added to this page are ongoing. Feedback and user input determines what is added to this page.

Note: We do not personally offer or give any project advice or help by e-mail or snail mail. We do, however, take on board any constructive criticism and make adjustments if warranted and we do try to supply help initiatives.

2.) There is also a glossary of terms which can be found in Section 20.1 Glossary.

The glossary gives an explanation of terminology (project words) used in this project.

Section 19.2. Help with measurement – Understanding the measurements

All measurements throughout this project are given in both Standard/Imperial inches, and Metric (mm).

The measurements are given first in inches, followed by millimeters (mm) in brackets ( ).

1 1/2″ x 3 1/2″ means wood that is 1 1/2 (one and a half) inches thick by 3 1/2 (three and a half) inches wide.

And the equivalent in metric…

90mm x 45mm means wood that is 90 millimeters wide by 45 millimeters thick.

The millimeter measurements are written opposite to the standard measurements. Why?

In North America they call the smaller side first. Example: 1 1/2″ x 3 1/2″

In Australasia they call the bigger side first. Example: 90mm x 45mm

The inch sizes are not an exact match to the equivalent millimeter sizes, because for rounding-off purposes we translate 1″ as being 25mm which is not exactly right but near enough..

A shed built using the metric measurements will be approximately 1.6% smaller (hardly worth worrying about) than a shed built using the imperial (ft and in) measurements.

In other words, use one or the other but do not mix the two (for those of you who can work with both standard and metric measurements) and you should have no problems as far as the dimensions go.

The imperial measurements are more suited to North America. The metric measurements are more suited to Australasia and other countries.

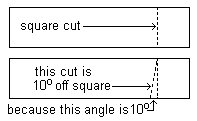

Section 19.3. Help with angles – How to work out the angles

Because of the sloping wall and the pitch of the roof, there will be a few different angles you will have to work with.

Sometimes throughout this project you will have to make some angle cuts across certain members.

Some of the angles may sound a bit daunting to figure out, but it is really quite easy once you know how.

There is a separate help file that explains how to pre-draw all the angles on a square panel and then, with an adjustable T-bevel, you can simply transfer the angles to the members that require angle-cutting.

Working with angles

Sometime throughout this project you will have to make some angle cuts across certain members.

Somewhere you will come across a sentence similar to…

“… cut one end of the wood 10° off square.”

What’s that?

Ok. Firstly, what’s a square cut?

A square cut is a cut that runs straight across a piece of wood.

Therefore, a cut that runs at 10° to the square cut, is a cut that is 10° off square.

All right! So how do we get the angles?

There are four different angles you will work with throughout this project.

They are a 10° angle, a 26.87° angle, a 36.87° angle and a 53.13° angle.

eh! They sound like awkward angles to try and work out.

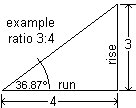

Not really, if you were talking slope (rise over run)

10° would be a rise of 1 for every 5.67 of run.

26.87° would be a rise of 1 for every 2 of run (or near enough).

36.87° would be a rise of 3 for every 4 of run.

53.13°. would be a rise of 4 in every 3 of run.

So, using the above ‘rise over run’ equation you can make an angle template by marking the required angles on a rectangle panel.

Getting the angles

- Make an angle template by marking the required angles on a rectangle panel, say a piece of plywood 18″ x 24″ (450mm x 600mm).

- To get a 10° angle, measure 1 unit across the rectangle panel and 5.67 units down.

Note: A unit can be any measurement. For example: if you make each unit 4 inches (100mm), then measure 4 inches or 100mm (1 unit) across and 22 11/16 inches or 567mm (5.67 units) down to make a 10° angle.

- To get a 26.87° angle, measure 1 unit across and 2 units down.

Note: Once again a unit can be anything. If your make each unit four inches (100mm), it would be 4 inches or 100mm (1 unit) across and 8 inches or 200mm (2 units) down to make a 26.87° angle.

- To get a 36.87° angle, measure 3 unit across and 4 units down.

Note: Once again a unit can be anything. If your make each unit four inches (100mm), it would be 12 inches or 300mm (3 unit) across and 16 inches or 400mm (4 units) down to make a 36.87° angle.

- To get a 53.13° angle, measure 4 unit across and 3 units down.

Note: Once again a unit can be anything. If your make each unit four inches (100mm), it would be 16 inches or 400mm (4 unit) across and 12 inches or 300mm (3 units) down to make a 53.13° angle.

You have now made a template for a 10° angle, a 26.87° angle, a 36.87° angle and a 53.13° angle.

Set the T-bevel gauge to the required angle and transfer it to any piece that requires that particular angle cut.

Section 19.4. Help with wood sizes – wood sizes used in this project

The wood sizes referred to in this project are the actual sizes and are not the nominal sizes.

The bulk of the shed framework is made out of 1 1/2″ x 2 1/2″ (90mm x 45mm) wood which is the actual size.

ACTUAL and NOMINAL (what that’s all about!)

It is easy to see why some people get confused when purchasing wood, as when you go to the supplier and ask for a particular stock size, sometimes what you end up with is a different width and thickness than what you asked for.

Why is this?

Well…

That’s because most wood is identified by it’s sawn size (nominal size) rather than actual size which is smaller due to dressing (planing) and/or drying.

NOMINAL SIZE (also called sawn or rough sawn) is the size of the wood when it is first sawn such as 2″ x 4″ (100mm x 50mm).

When the sawn wood is seasoned, dressed or planed the size becomes smaller which is the ACTUAL SIZE.

Therefore….. A piece of 2″ x 4″ (100mm x 50mm) wood (nominal, sawn size) may become approximately 1 1/2″ x 3 1/2″ (90mm x 45mm) which is the actual size.

By the way, some countries that use the metric system put the bigger number first (100×50) and countries that use the imperial or standard system put the smaller number first (2×4).

Two questions please:

1.) Any recommendations for finishing on the sides regarding weather proofing? Would a Kiltz style primer followed by a finish coat of white acrylic be best for moisture proofing (with caulk as needed)?

2.) Any recommendation for whether to use pressure treated wood to prevent termite issues? I do plan to raise it off the ground with concrete but still concerned as I have lots of mulch in neighborhood of shack. Plan to use it on bottom runners, but is it a good idea at other locations? Seal bottom, ground facing portion with vinyl? Thanks!