Contents

A good bench vise can make your work safer and more comfortable by providing stability for your workpiece. However, vises are manufactured with a specific purpose in mind, so you’ll find that options range in clamping pressure, mobility, and the materials they can hold.

We tested numerous bench vises in an effort to help you find the one that will fit your workshop best. We put together these reviews and a list of features to help rule out vises that won’t be helpful for your intended work.

Best Bench Vises – Our Top Picks

BuildEazy.com may earn a commission if you purchase a product through one of our links.

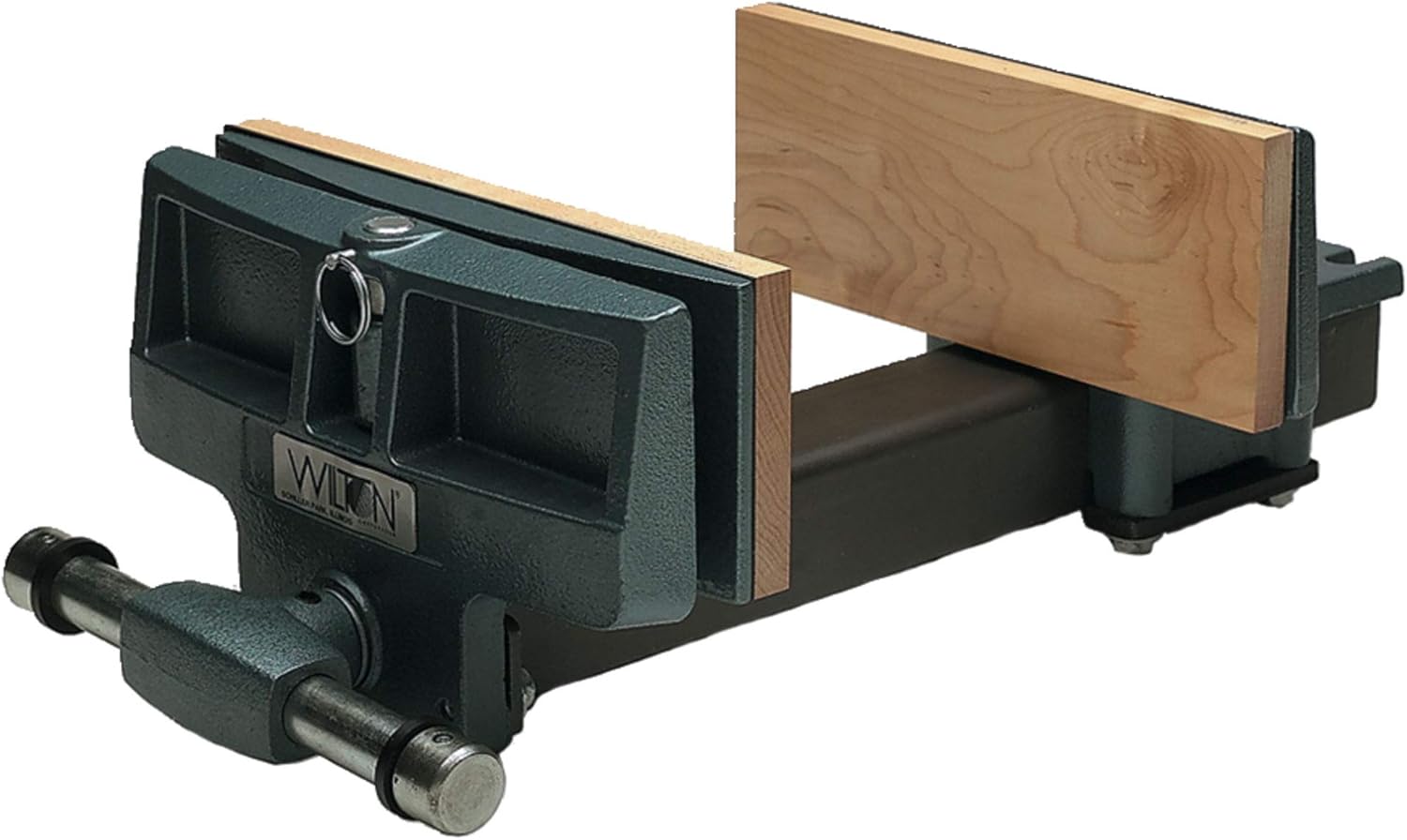

Wilton specializes in durable and robust clamping devices that are suitable for professional use, and their expertise shines through in this vise.

It’s made of very high-quality metal and wood, and we’re confident that it will last for many years without showing signs of wear and tear. It weighs a hefty 30 pounds, but the weight shouldn’t be an issue once it’s in place.

The adjustment knob is smooth and fast and allows plenty of leverage to get a solid clamping pressure on your workpiece.

This vise is designed for woodworkers and has wooden plates inside the jaws. These allow tight clamping of pieces of wood without marring the surface of your stock.

The jaws open up to a maximum of 10 inches to allow you to work with wide pieces or multiple pieces of wood at once. They are 7 inches long with a throat depth of 4 inches to hold a wide range of material securely.

Our favorite part about this vise is the quick-action adjustment. A single turn of the adjustment knob to the left will knock the jaw out of its locking position and allow you to move it freely. When you’re ready to clamp again, the jaw quickly matches the width of your stock with just a few turns to the right and then begins securing. The result is the ability to release stock and quickly re-clamp with one hand in a matter of a few seconds.

The vise is simple to set up, and you will just need to mount it to the bottom of your bench. You may need to plane a piece of hardwood down to the proper thickness to get the top of the jaws to sit perfectly level with your bench, but this is standard practice for all woodworking vises.

Wilton provides a lifetime warranty for this vise, so you can be confident in your purchase that it will work as intended for as long as you plan to use it.

Capri Tools 10515 Ultimate Grip Bench Vise

Capri prides itself on making reliable tools that are ideal for tradespeople and home shop owners alike.

This vise is made out of very durable forged steel, and it feels like it will last through years, if not decades, of heavy use and workshop abuse. It weighs in at 23.8 pounds and is more or less immovable once you’ve mounted it to your bench.

This is a top-mount vise, so you’ll have to drill through your benchtop to secure it. This isn’t ideal for woodworking projects where you need a clamp that’s level with your work surface, but it should suffice for most projects.

The adjustment knob is quick enough for most purposes but doesn’t have a quick release. However, the lever style handle offers tons of leverage to get your workpiece clamped down adequately. It’s capable of creating 5,500 pounds of clamping force, so you can be entirely confident in its ability to keep your stock from moving around.

The jaws have hard rubber pads on them that offer an excellent grip on most materials. It’s ideal for woodworkers who want the ability to work with different stock, like metal, PVC, or other plastics. The jaws are textured to provide a no-slip grip on most workpieces. It also includes rounded jaws to aid in pipe or dowel clamping.

The jaw opens up to 5 inches, which allows the freedom to work with most material thicknesses. The throat depth is only 2.9 inches, which is smaller than most woodworking vises but suitable for most jobs you’ll do around your shop.

The best part about this vise is its ability to rotate. The base swivels 360 degrees and can be locked securely in place with a separate adjustment knob. This rotational adjustment allows you to clamp your piece and then position it to make your work as straightforward and comfortable as possible.

The vise has a small, flat area behind the jaws that can be used as a mini anvil for metal shaping.

Olympia Tools Bench Vise 38-606

Olympia manufactures tools meant for heavy use by hobbyists, and that’s precisely what you can expect from this vise.

It’s made from cast iron and feels indestructible. We’re certain this will last through many years of frequent use without breaking down or getting damaged. It’s very heavy at 30.4 pounds.

The adjustment knob features a swivel-lock design to make tightening and loosening the jaws quick and painless. The swiveling lever is long and allows for plenty of leverage to make clamping comfortable. The clamping pressure isn’t the best, and you likely will experience some minor movement of your workpiece.

This vise is ideal for metalwork. It has textured steel jaws that will mar any type of wood you try to use it with, but they will hold metal stock securely and without the chance of slipping out. You can use it to work with wood, but you’ll need to use scrap pieces to protect your stock, which can be a bit of a pain.

This vise has a small anvil area built in, which you can use to shape small pieces of metal.

The jaws open up to 6 inches, making them suitable for use with wide workpieces. The throat depth is 3⅛ inches, and the vise includes rounded jaws below the square jaws. These will let you clamp round stock like pipes or dowels safely without the risk of your piece slipping out.

This vise includes a swivel base that lets you swing your clamped workpiece up to 270 degrees. You’ll be slightly limited in the angles you can hold your piece, but the movement should be plenty for most purposes. You can lock the base with a separate adjustment knob to keep your work firmly in place.

Although it’s not the most secure and immovable vise when it’s clamped, it is one of the most affordable vises we tested.

Forward DT08125A Heavy Duty Bench Vise

Forward produces vises that are best for hobbyists on a budget who still want secure and stable clamping.

This vise is made out of ductile iron forged at 60,000 PSI, so it will outlast just about any project or workshop abuse you can throw at it. It weighs a hefty 35.2 pounds, so it’s one of the heaviest vises we tested. Forward built this tool to last, but it’s also beautifully finished and looks like a polished workshop piece.

It features a swivel-style adjustment knob that creates a long lever arm for supplying plenty of clamping pressure. You won’t experience any movement in the stock you use. It doesn’t have a quick release, but the adjustment is fast enough where you won’t miss it for most projects.

It’s best used for metal, as the jaws have textured steel that will mar softer materials like wood or PVC. However, this is a very versatile vise for metalwork that excels at clamping different material shapes. The block-style jaws let you clamp a variety of metal pieces, and the swiveling clamp arm can be adjusted to reveal bar clamps that are perfect for holding rounded material securely. It includes jaws to hold pipes vertically and horizontally.

The jaws open up to 5 inches, so they’re suitable for wide material, and the throat depth is 2.6 inches. The depth capacity may slightly limit you, but it should be plenty for most purposes.

This vise swivels on two planes to give you unlimited clamping options. It’s attached to a swivel base that allows 360 degrees of rotation, and you can rotate the clamping arm freely as well. You’ll be able to hold your stock in just about any position to make it most comfortable. The swivel action can be locked with adjustment knobs for safety while you work, and the thick base lock will prevent any movement.

Forward included an anvil on the rear portion of this vise for shaping metal stock.

TEKTON 54004 4-Inch Swivel Bench Vise

TEKTON focuses on manufacturing low-cost tools that still bring plenty of value to hobbyists and casual users. This is our favorite budget vise, and it is one of the most affordable vises we tested.

Despite its low price, it’s made out of cast iron and is very durable. It feels like it will stand up to regular use without much issue at all. It weighs only 14.8 pounds and is a bit smaller than most other vises we tested.

It has a swivel-style adjustment knob that gives you plenty of leverage to apply good clamping force. The knob is comfortable to use and rotates smoothly.

It’s ideal for metalwork, as the jaws are made of textured steel that can easily create indents or scratches on wood or plastic surfaces. You could use this vise to clamp wood pieces if you make custom jaw inserts or use protective scrap pieces.

The jaws only open to 4 inches, but the vise is available with 6-inch and 8-inch jaw openings as well. You’ll have a range of options to choose from depending on the stock you plan to use it with, but the larger jaw openings are significantly more expensive. The throat depth is also minimal at 2⅛ inches, so this vise isn’t the best for gripping more extensive stock regardless of which jaw opening you choose.

The vise is set on a swivel base to allow for some adjustment. It can be moved up to 120 degrees, offering less mobility than many other swivel bases but still providing some clamping options for comfort. You can lock the base with a simple swivel-style knob.

It has three brackets to mount it securely, and you’ll have to drill through the top of your workbench to attach it.

This vise has a relatively large, flat patch of metal that can be useful for shaping or flattening metal.

Yost Vises 750-DI Multi-Jaw Rotating Pipe Vise

Yost is well-known in the woodworking and metalworking industries for making high-quality clamping devices that are secure and powerful. This vise holds up that reputation.

It’s made from 65,000 PSI ductile iron, which is very strong and more or less indestructible. This is likely to outlast just about any other tool in your shop, even with heavy use. The metal is very heavy-duty, and it’s one of the heaviest bench vises we’ve ever used at 63 pounds.

The adjustment knob is a swivel-style lever that allows immense clamping pressure of up to 13,400 pounds, and the leverage provided makes clamping your stock quick and comfortable. It’s a polished metal that is easy to handle as well.

This vise is ideal for metalwork because the steel jaws are textured and will mar wood or other soft materials. Yost designed this tool for use with a variety of metal workpieces, so it will make working with pipe or slick surfaces safe and secure.

The jaws open up to 5 inches, and the vise has an impressive 4-inch throat depth. You won’t be limited much in the size of the material you can clamp with this vise. There are flat jaws for clamping standard metal pieces, as well as rounded jaws for holding round material vertically or horizontally.

The vise includes a swivel base that rotates 360 degrees. This adjustability lets you hold your stock in the most comfortable position while you work. The clamping arm also rotates 360 degrees and can be clamped in increments of 30 degrees, allowing some freedom in the orientation of your workpiece for comfort and convenience. You can secure both rotational adjustments in place, and the locks allow for no noticeable movement.

The base has four mounting holes to help provide one of the most secure and stable vises we’ve used.

Yost built in a mini anvil with one flat end and one rounded end, which can be useful if you do metalwork.

IRWIN Tools Multi-Purpose Bench Vise 4935505

IRWIN has been making reliable tools for tradespeople and hobbyists for over 100 years, and this vise exemplifies their experience and expertise.

It’s made entirely out of steel and feels very durable. The adjustment knobs and the anvil are beautifully polished and make the vise quite visually appealing. It weighs 33.1 pounds and will sit solidly on your bench once mounted.

The swivel-style adjustment provides plenty of leverage to clamp your workpiece without too much effort. The vise has an excellent clamping pressure that will hold your stock steady while you work.

It’s made predominantly for metalwork. It can be used to clamp wood pieces, but the textured jaws will scratch softer materials and create indentations in wood or plastic surfaces unless you use scrap to protect them.

The jaw opens to 5 inches, so you can use them to clamp wide material securely. It features a 3-inch throat depth that won’t limit you much in the stock with which you can use it. The clamping arm has two sides: one for holding standard metal pieces and the other for securing pipe vertically or horizontally.

IRWIN mounted this vise on a swivel base that rotates 360 degrees. The clamping arm also swivels 360 degrees. You can lock both rotational adjustments in any position, so there are unlimited possibilities to how you can clamp your piece.

The vise has four holes for benchtop mounting, and it will provide as much stability as your bench will allow.

There’s a small anvil built into this vise for use with metal stock.

Especially given the affordable price, we think this vise provides excellent value for the money.

HFS Heavy-Duty 6-Inch Bench Vise

HFS specializes in budget tools for tradespeople, which are often high-quality options for hobbyists.

HFS made this vise out of cast steel, so we’re confident it will stand up to plenty of workshop use without any problems. It’s quite a bit smaller than most other vises we tested, but the highly durable construction materials bring this vise to 32.3 pounds.

The vise is somewhat utilitarian and isn’t nicely polished, so this is best for those who care more about performance than appearance.

The adjustment knob is a swivel-style with no quick release, but it’s simple enough to clamp and unclamp quickly without too much effort. The leverage you get from the lever allows for plenty of clamping pressure for most applications.

This bench vise is ideal for metalwork rather than woodworking applications. The steel jaws can easily damage soft materials. You can opt to use scrap pieces as protection if you plan to work with wood or plastic, but this can be quite tedious, especially if you’ll be adjusting frequently.

The jaws open to 5.9 inches to allow plenty of room for wider stock. The throat depth is only 3 inches. You won’t be able to clamp larger pieces securely, but the clamping arm does provide a nice, flat surface to rest stock on while you position it within the jaws.

The vise is mounted on a swivel base that can turn 360 degrees. It has a locking mechanism to prevent unwanted turning while you work. The vise will hold your piece securely, but the adjustment knob to lock the base in place is very thin and can be a bit of a pain to tighten adequately.

This vise is simple to set up and mounts securely with four bolts.

There’s a small section of flat steel built into the top of this vise. This area can be useful for metal shaping applications.

HFS only includes a 1-year warranty on this tool, but we still think it brings excellent value for the relatively low price.

Wilton 11106 6-Inch Bench Vise

Wilton is well-known in the woodworking and metalworking circles for quality clamping devices, and this vise will prove why.

It’s made of durable steel, so it’s likely to last through just about any project you have in mind. Wilton stands behind this vise with a lifetime warranty, so you can be confident that you’re purchasing a tool that will last. It weighs a hefty 38.9 pounds.

This vise is beautifully polished and is very visually appealing. The adjustment knob is smooth and comfortable to use, and it gives you enough leverage to supply plenty of clamping pressure to hold your stock in place, even through heavy work.

It’s designed predominantly for metalwork. The textured steel jaws will provide a no-slip grip on slick metal surfaces, and the anvil includes a shaping plane for hammering metal into shape. You can use this with softer materials, but you’ll have to protect them from the jaws with scrap pieces.

It opens up to an impressive 6 inches, so you’ll hardly be limited in the width of stock with which you can work. However, it does have a relatively small throat depth, so the vise won’t hold very large workpieces easily.

It comes on a swivel base that lets you rotate your clamped stock to a comfortable working position. It rotates 360 degrees but uses a locking mechanism that effectively limits you to around 300 degrees of movement. It still provides ample freedom for comfort and convenience. The adjustment knob to lock the rotational movement is easy to use.

This vise has four mounting holes that let you secure it to the top of your bench. The mounting brackets make for a very solid and stable work surface.

Wilton built in a large anvil section behind the jaws, which is an excellent addition for metalworkers.

Pony 27091 8-Inch Medium Duty Woodworker’s Vise

Pony Jorgensen specializes in light -and medium- duty clamping devices for casual use, and they provide excellent budget options for woodworkers.

This vise is made out of cast iron. It’s much less bulky than the other vises we tested, and it weighs in at just 11.8 pounds. Despite its lighter weight, it still feels durable and solid, and we’re confident it will continue to function well through many projects.

The adjustment lever on this vise is one of our favorites, as it’s very large and provides plenty of leverage and motion for easy turning and quick adjustments.

This vise is made specifically for working with wood materials. It has a very large clamping surface on both jaws that is smooth metal, so it won’t damage wood or plastic stock, even when clamped down securely. The rapid adjustments let you dial in clamping pressure for different thicknesses as well, so it’s suitable for use with a wide range of wood sizes.

The jaws open up to an impressive 7 inches and won’t limit you much in the width of the material you can clamp. It features a large throat depth, so it’s suitable for securely clamping more extensive stock.

There is no quick release on this vise, so you’ll need to make any adjustments manually.

You can mount this from the side and the bottom, so set up is a breeze. You’ll be able to align it with your bench’s surface for the most versatility.

This is one of the most affordable vises we reviewed. It only comes with a 1-year limited warranty covering manufacturing defects. Even with the limited nature of the warranty, we think this is an excellent option for hobbyist woodworkers or “weekend warriors” looking for decent clamping pressure.

Buyer’s Guide

We’re sure it’s easy to see that bench vises aren’t all created equal, so make sure you keep the below features in mind.

Types of Bench Vises

You’ll first need to choose the kind of vise that will fit your bench and the types of projects you do. There are several different types from which you can choose.

Woodworker’s Vise

A woodworker’s vise is, of course, designed for use with wood. The jaws always have large, smooth clamping surfaces to distribute pressure evenly across a wide portion of your stock. They won’t create indentations in soft materials, so they’re safe to use with softwoods and plastics.

The jaws aren’t textured, so they won’t mar the surface of your workpiece. They’re often made of metal but include wood faces to provide the best protection for your stock.

Since wood pieces often come in the form of wide planks, the throat depth of a woodworker’s vise is typically more significant than that found on other vise designs. A throat depth of 4-6 inches or more is typical, which provides enough clearance to clamp large pieces of wood securely.

Higher-end woodworking vises, like the Wilton Pivot Jaw 63144, have a quick-release mechanism that lets you adjust the jaws rapidly. This feature is useful for moving between different workpieces and thicknesses rapidly.

Woodworking vises also usually mount to the bottom of your bench, which lets you line up the top of the jaws with the top of your work surface. This alignment makes it easier to create 90-degree joints and aligns other joinery types.

Check out the below video for tips on installing a woodworker’s vise:

Engineering Vise

An engineering vise is designed to be used with metal stock. The jaws are significantly smaller than those on a woodworker’s vise, and they’re often made of textured steel designed to grip slick metal workpieces.

You can use the textured jaws to clamp wood, but they are sure to mar the surface and leave indentations, which can ruin a project’s appearance. The alternative is to use wood scraps as a buffer between your stock and the jaws. However, they are challenging to set up correctly and can be a pain when it comes to adjusting your stock.

It also optimizes precision and stability by reducing the points of adjustment and rotation. They generally only offer one clamping position, but they tend to keep your clamped piece perfectly immobilized and lend themselves to very little wiggling or shifting.

Pipe Vise

A pipe vise is designed to hold cylindrical objects like pipes or dowels. They have angled or round jaws that wrap partially around your workpiece and keep it in place as you work.

They are designed to be used with metal stock. They typically have steel jaws that would mar the surface of wood, although you could use them to hold wood dowels. They’re made to prevent a round piece of metal from spinning and are usually too sharp to hold a dowel securely without damaging it.

Pipe vises are often used by metalworkers, electricians, and plumbers.

Mounting Location

There are multiple mounting options for bench vises, each unique to the circumstances under which you intend to use it.

Benchtop Vise

A benchtop vise is bolted directly onto the surface of your workbench. It usually has three or four mounting brackets that will be attached to holes drilled in your bench with nuts and bolts.

Vises mounted to the top of the bench are useful if you have limited space in your shop and can’t fit side- or front-mounted vises usefully on your bench.

For a comprehensive guide on mounting a benchtop vise, check out this video:

Front Vises

Front vises are mounted to the front of your workbench. They’re most often used for woodworking, as they are set up such that the jaws are level with the work surface. They’re designed to take up limited lateral space when fully closed, but they do jut out a bit more than your vise’s jaw width when fully opened.

They’re most useful for holding wood stock while you drill, saw, or join pieces.

End Vises

End vises –sometimes referred to as tail vises – are similar to front vises but are usually mounted on the side of the workbench. They use the benchtop as the inner jaw. The outer jaw typically has a rectangular or circular hole drilled into it that can be used with bench dogs to hold workpieces in place on top of your bench.

For a detailed look at how you can use bench dogs with an end vise, check out this video:

Features

Vises made for different purposes have varying features that can make or break your project and dictate how useful and versatile they are in a shop.

Jaw Width

Jaw width is a measurement that describes how wide the clamping surface on your jaws is. Vises don’t have side braces, so the jaw width won’t limit what length stock you can hold. However, thinner jaws offer less friction against your workpiece and will provide less support for longer material.

Throat Depth

Throat depth is the measurement from the top of your vise’s jaws to the top of the screw mechanism. It dictates how much of the material can fit below the uppermost level of support you’ll get from your vise’s jaws.

A small throat depth will limit the overall size of the stock you can clamp comfortably. Larger pieces clamped in a vise with a limited throat depth will naturally twist and move more readily, potentially making your stock unstable and your work unsafe.

However, the larger the throat depth, the more force is placed on your clamping jaw. Most manufacturers limit the throat depth to provide safe and reliable clamping pressure.

A considerable throat depth can also make it rather annoying to align a workpiece if you’re using scrap pieces to protect your stock. You’ll need to hold your stock and the two protective pieces in place with one hand while you tighten the vise with the other.

Swivel Rotation

Many vises are mounted to swivel bases that can be unlocked and rotated on a plane parallel to your workbench. Swivel bases let you move your workpiece into a more comfortable and convenient position for you to work but still hold the piece firmly in place when locked.

Swivel bases generally have a separate swivel-style to tighten the base and prevent unwanted movement. With a second, smaller lock, there is more room for movement and more that can go wrong with your vise. However, most hold your piece securely and prevent wiggling or shifting while you work.

Mount Type

There are two different mount types for benchtop vises: those that clamp on and those that bolt on.

Clamp-On Mounts

Clamp-on mounts use a separate screw mechanism located below your bench to clamp the vise itself to the benchtop. They don’t require you to drill holes in your work surface, but they are generally less secure and can loosen while you work. You do have the added benefit of being able to relocate them if you choose.

Bolt-On Mounts

Bolt-on mounts require that you drill holes through your bench and attach the vise using nuts and bolts routed through the drilled holes. They’re more invasive and will leave permanent holes in your work surface, but they’re typically more reliable and present a more stable base for your vise.

Anvil

Many vises designed for metalwork have a small, flat portion behind the jaws that serves as a mini anvil. These aren’t very useful when you’re working with wood, but you can use them to shape small sections of metal. Some woodworkers find them useful when adding metal elements to wood-based projects.

Quick Release

Tightening and loosening your bench vise can be a bit tedious if you’re working with materials of different thickness or if you need to adjust regularly. A quick-release can help make your job significantly more comfortable and faster by reducing the time it takes to open and close your vise.

Some quick releases involve a locking pin that you can pull to free up the screwing mechanism on your vise. This lets you slide the jaws to about the desired width before re-locking and making smaller changes with the adjustment knob.

Like the one on the Wilton Pivot Jaw 63144, other quick releases can be used seamlessly with one hand and make rapid adjustments for you. Simply loosening the adjustment knob by one turn or more will engage the quick release automatically.

Size & Weight

The size and weight of your vise will be most important if you purchase a clamp-on vise that you plan to move around your shop and store as needed. Bulkier, heavier clamp-on vises will be more challenging to relocate and take up more storage space.

These will be less important if you’re choosing a bolt-on vise, as you’ll only have to position the tool once. However, a heavier vise is often indicative of more robust material.

Jaw Opening

Jaw opening is the measurement that describes how wide your vise’s jaws can open. The maximum distance will limit the thickness of the stock you can clamp, so it’s an important decision to make. It can determine the types of projects for which your vise will be useful.

Most engineering vises have a jaw opening of 3-5 inches, while woodworkers’ vises often accommodate between 6- and 8-inch material.

Durability & Build Quality

Bench vises often take quite a bit of abuse because they’re usually on the end of your most-used piece of shop furniture –your workbench – and are regularly exposed to damage. Despite having to stand up to heavy use, they need to perform appropriately to maintain a safe work environment.

Durable bench vises that are made out of cast iron or steel will be all but indestructible. Those that are also built well will stand up to the test of time while delivering consistent and safe support for your projects.

Price

Vises range quite a bit in price, depending on the type you’re looking for and the features you need for your intended use. More expensive vises will usually have more desirable traits, hold your material more securely, reduce movement while you work, and have a better build quality that will last for years if not decades of extensive use.

Material Used

The material used to construct a bench vise can have a significant impact on both the longevity of your tool and the associated price tag.

Cheaper vises use plastic and rubber parts. These materials are far more affordable but will never outlast an all-metal vise. They’re usually suitable for very light-duty use.

Cast iron is very durable and will outlast plastic and rubber parts every time. Forged iron is a bit stronger than cast iron, and steel – which is iron with added carbon – is the most robust material you can choose for a vise.

Intended Use

No matter what features you’re looking for in a vise, the projects for which you intend to use it will most often dictate the type of vise you should choose.

Cutting Conduit

A pipe vise will best serve electricians or handy homeowners who need to cut conduit. It has a rounded or angled set of jaws designed to hold cylindrical material like electrical conduit securely and prevent it from spinning while you work.

Drilling or Sawing

A woodworker’s vice will be most useful if you’re drilling or sawing wood. They’re designed to hold wood stock securely in place and use high friction to prevent movement.

If you’re drilling flat metal, an engineering vise will serve you best. It will prevent your slick stock from slipping while you operate your drill with both hands.

Gluing

An end vise made for woodworking is most suitable for gluing. It effectively transforms your entire workbench into a giant vise with the use of bench dogs, allowing you to glue large pieces or multiple pieces simultaneously.

Metalworking

An engineering vise is likely your best option for metalwork. They have textured jaws designed to grip slick material and prevent slipping and movement even during heavy use. Many engineering vises also include a small, flat section of metal located behind the jaws that you can use as a mini anvil for shaping and flattening metal stock.

Sanding or Planing

A woodworker’s vise is usually the most apt for use when sanding or planing. They’re designed to secure pieces of wood and will resist the heavy lateral movement involved with these actions.

A front-mounted woodworker’s vise will be the best for planing. An end vise or tail vise would be better for sanding, as they are ideal for holding very large workpieces in place on your benchtop.

Frequently Asked Questions

Where Should A Bench Vise Be Placed?

The location in which your vise should be placed on the bench depends on what kind of vise it is.

For example, a face vise should be installed on to the front of the bench whereas other vises are attached to the side of the bench.

If you are right-handed, it is recommended that you install the vise on the far left of the bench at the front edge and if you are left-handed, you should do the opposite.

For the face vise, you should get one that is a bit larger as this is the one you will be using for planning edges and other general tasks.

For the end vise, you can go for something that is a bit smaller than it will make it easier to clamp workpieces.

When you install the vise, the stationary jaw should project slightly beyond the workbench’s edge.

This prevents you from being limited to what length you can clamp into the vise as the edge of the workbench won’t get in the way.

What Are The Main Parts Of A Bench Vise?

There are many little components that go into a bench vise which makes it a very handy contraption to attach to your workbench.

There are seven main components to the bench vise that we will be covering which will give you strong base knowledge as to how they work.

Handle

This is the part of the vise that you turn to tighten the jaws and has been designed to bend if you apply too much pressure to it which is called ‘over-torquing’ and should be avoided.

Another reason why you should be careful with the handle is that as you turn it, the power is multiplied by the main screw so if you see it bending, it’s a good sign to stop.

Main Screw

This is where the power is fed through the vise to make the sliding jaw move toward the static jaw.

Since the main screw is so important in a vise, it should be of good quality as flaws will cause the vise to be much weaker than it should be. A good screw allows you to apply a lot of pressure and maintain it.

Slide

The slide is what the sliding jaw is attached to, it moves when the handle is turned which in turn closes the gap between the jaws.

Static Jaw

Hence the name, this jaw doesn’t move, it is part of the base which is the biggest part of the vise.

Sliding Jaw

This is the jaw that moves toward the static haw as you turn the handle.

Base

The base holds everything together and is the part that you secure to the workbench.

There are different types of bases with some being designed to clamp into place with others needing to be bolted down.

Anvil

Usually only found on metalworking vises, this is the part that allows you to lightly shape some materials, it can also be used as a base for hammering small objects.

Wrapping Up: Which Bench Vise is Best?

No bench vise is an adequate solution for all clamping applications. Each is designed to be used in a specific way, for a different function, or with a particular stock type. The best bench vise is the one that is most applicable to the work you do and the way you intend to use it.

Our favorite for use in most woodworking projects is the Wilton Pivot Jaw Woodworker’s Vise 63144. It provides excellent clamping pressure, and it’s designed for wood and won’t mar or dent your workpiece. The quick-release and stability it provides make it our top choice for versatility, ease of use, and safety.