Contents

Wood is at the core of everything we do as woodworkers, but, unfortunately, it breaks down and weakens over time, losing strength and visual vibrance.

Wood hardeners help restore some integrity to your older projects and prevent additional decay. Not all wood hardeners are created equal, as some offer less strength than others, and some are potentially dangerous to use in certain situations.

My reviews and comprehensive buyer’s guide below will help you choose the best and safest wood hardener to bring life back to your past work.

Best Wood Hardeners – My Top Picks

BuildEazy.com may earn a commission if you purchase a product through one of our links.

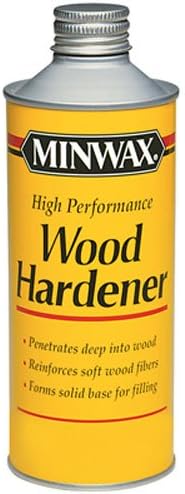

Minwax is a highly trusted brand when it comes to varnishes, conditioners, and fillers. I use their products for staining, clear coating, and filling more than I use any other brand.

This wood hardener is very easy to apply, as it has a thin, watery consistency. You can brush this on with ease or opt to use it with a spray bottle for more even coverage. However, it may drip if you’re applying it to vertical surfaces.

It soaks into the wood rapidly and dries very quickly. While the drying speed means less time waiting around for the hardener to dry, it also makes it challenging to correct unevenness in the application, as you’ll have very little time to make adjustments.

It provides excellent strength because it soaks deep into the wood you’re curing. While you shouldn’t rely on any hardener for structural integrity, this one does appear to give some significant support to damaged wood.

It’s waterproof once it’s dried, so you can use this on material that will remain outside, like decking or lawn furniture.

It will somewhat change the appearance of the wood you’re treating, making it a bit darker. As such, this isn’t ideal for separate pieces of a project, as they will stand out once treated. However, it makes the grain pop and leaves a beautiful, stain-like finish.

Like most effective wood hardeners, this one contains some potentially dangerous compounds. Wear rubber – not latex – gloves and a respirator when applying this hardener, and never use it in an enclosed space without ample ventilation. Keep it away from flames or sparks at all costs.

PC Products PC-Petrifier Water-Based Wood Hardener 84441

PC Products specializes in adhesives, sealants, and other quick fixes for homeowners, auto enthusiasts, and woodworkers.

This wood hardener has a mid-range viscosity, and it’s significantly thicker than the Minwax hardener. It takes a bit more effort than thinner options to apply evenly, but the thickness lends itself to an easy application to vertical surfaces.

Check out this video for application tips and uses:

This hardener comes in a small bottle with a tiny applicator tip, making it an excellent option for precision jobs on smaller projects. You can also place it in a spray bottle for easy application to larger areas.

It soaks into the wood and begins to harden quickly. However, you’ll need to let it sit for several hours to get it to dry completely, so it’s a bit less convenient to use than quick-drying options.

It works well to harden rotted or weakened wood, but it doesn’t add much in the way of structural integrity. PC Products doesn’t recommend it for use on wood that offers support in any way, so it’s likely to add less strength overall.

This hardener is waterproof, making it a good option for indoor and outdoor projects.

It dries clear, but it adds a poly-like appearance to the surface. Additionally, the wood you apply this to will appear a bit darker than untreated areas, so it’s not ideal for spot hardening.

This hardener is environmentally friendly, but it does contain chemicals that can be dangerous to humans and pets. Make sure to wear proper safety gear, including rubber gloves, eye protection, and a ventilator when applying. Never use this in an unventilated area or around open flames.

Bondo All-Purpose Putty

Bondo is a highly trusted brand when it comes to adhesives and strengtheners, and the strength their products supply is often suitable for professional use.

This wood hardener comes in the form of putty, and it’s significantly thicker than most other options. You can paint it on, but the viscosity can make brush application challenging. I found it much more straightforward to use a putty knife to apply it.

Given how thick the putty is, it’s an excellent option for vertical surfaces and is very unlikely to drip.

It doesn’t soak deeply into wood surfaces, and it’s better to use for repairing cracks and restoring tensile strength in your projects.

It dries very quickly and is ready to shape and sand in just 15 minutes. However, I do recommend letting it sit for about 24 hours, especially if you have above- or below-average temperatures in your area.

This Bondo product offers quite a bit of integrity to wood. It’s multi-purpose and can be used to seal cracks in concrete home foundations, so I’d feel comfortable using this on wood pieces bearing moderate weight.

It provides a waterproof seal, so you can use it on outdoor projects without worrying about rain or snow affecting its strength.

This is a topical hardener that doesn’t soak much into wood. It will drastically change any surface’s appearance, so it’s not ideal for visible wood pieces. I would recommend this for surfaces you plan to paint after integrity is restored.

This compound contains potentially harmful chemicals, so make sure you take all of the proper safety precautions detailed in the instructions. It leaves an undesirable odor on your project at first, but it dissipates fairly quickly.

J-B Weld 50151 WoodWeld

J-B Weld is widely known throughout the woodworking, automotive, and home repair industries for their high performance, reliable adhesives.

This is a wood epoxy, so it’s relatively thick and can be a bit challenging to apply. I recommend using the provided applicator or a putty knife rather than a brush. This hardener is easy to mix, but it can be a bit time-consuming to spread evenly because it’s so thick. It will be easy to use on vertical surfaces and won’t drip at all.

It doesn’t soak as deeply into the wood as a water-based hardener, but it still provides excellent strength. J-B Weld notes that it maintains an impressive tensile strength of 1,800 PSI. As such, this is suitable for wood pieces that bear some weight.

It dries within 5-10 minutes but requires about 3 hours before it’s fully set. I recommend waiting even longer to be entirely sure that it’s cured before putting weight back on the material. The rapid drying time can make it difficult to fix any mistakes while you work.

The bond it creates is waterproof, so you can use this hardener with confidence on outdoor projects.

It will barely change the wood’s appearance to which you apply it, making it an excellent option for localized application or for treating just a portion of a project. You can also paint over it if you choose.

This product contains hazardous chemicals, and you should only use it with adequate safety precautions. Make sure to use it in a well-ventilated area with rubber gloves, eye protection, and a respirator.

J-B Weld 40001 Wood Restore Liquid Hardener

J-B Weld is a trusted brand for bonding agents, and their products are widely used by woodworkers, as well as home improvement DIYers and professionals.

This hardener is water-based and has a very low viscosity. It’s effortless to apply with a brush or a spray bottle, and it’s easy to get a smooth and even coat on most projects. However, it’s not ideal for vertical surfaces because it tends to drip.

It visibly soaks into wood very quickly, and it dries completely in just 2-4 hours. I recommend waiting up to 6 hours to ensure that the curing process is complete before allowing your project to bear any weight.

It seems to provide excellent strength to wood, even if it is heavily damaged and rotted. I wouldn’t use this for structural repair, but I’d be confident enough to use it on furniture.

In addition to hardening the wood to which it’s applied, this product creates a waterproof seal that soaks deep into wood and will continue to protect it from moisture in the future. It’s one of my favorite hardeners for outdoor use because of its added waterproofing capabilities.

It will alter how the wood you apply it to looks. Treated sections of wood will get darker and glossy once the product cures. As such, I recommend applying it to an entire project or on non-visible portions of the wood. You can also paint directly over this hardener, so it’s good to use on projects you plan to cover with color as well.

Like most wood hardeners, this product contains chemicals that should not come in contact with skin or eyes, and you should take care not to breathe in the fumes. Always apply this outdoors or in a highly ventilated indoor area. I strongly recommend wearing rubber gloves and a face mask while you work.

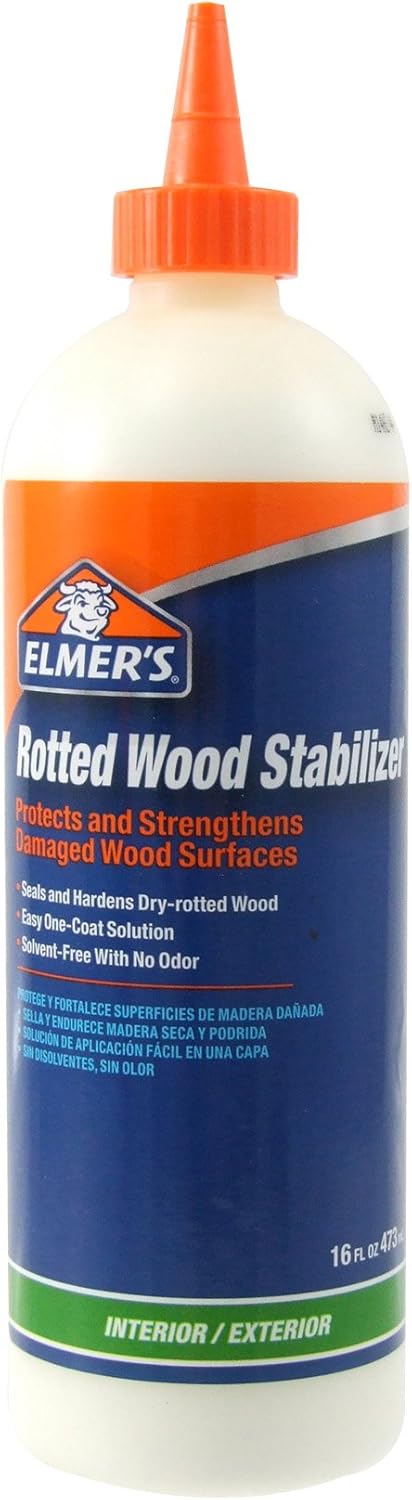

ELMER’s Rotted Wood Stabilizer E760Q

ELMER’s is one of the most recognized and trusted names when it comes to adhesives and strengthening products.

This hardener is about the consistency of standard ELMER’s glue, so it’s more viscous than water-based hardeners but not quite as thick as epoxy options. It’s reasonably simple to apply this to wood surfaces with a brush, but you could opt for a rag or sponge as well. It’s not the best option for treating vertical surfaces, as it’s likely to drip as it cures.

This hardener dries very slowly, so you’ll have to set aside ample time for curing. I found that it was still somewhat wet to the touch even after several hours, and it wasn’t until the next day that it felt dry. It should be left to soak in and cure for a few days for the best results.

It seems to add a fair amount of strength to wood, even if it’s heavily rotted. I wouldn’t rely on this product to add much structural integrity, but it seems to stop the rotting process and will keep your project in good condition for an extended period.

This hardener is not waterproof, so you should not use this on outdoor projects or those that may be exposed to moisture or water.

It will change the appearance of the treated wood a bit but not too drastically. It will appear slightly darker and have a semi-gloss look to it, so I recommend using it on an entire project rather than on specific locations.

This hardener contains no solvents, is non-toxic, and has fewer harmful chemicals than other hardeners. It’s the safest option, but I still recommend taking proper safety precautions and limiting any kind of exposure. The lack of harmful chemicals means there is no odor when applying this hardener.

Abatron LiquidWood 2-Part Structural Epoxy Wood Hardener

Abatron manufactures a wide variety of epoxies, sealants, and other topical treatments for added strength and longevity of different materials.

This epoxy comes in two different cans that you’ll need to use together. You’ll need to do some mixing before using this hardener, which will take more of your time than using a pre-mixed solution.

For detailed instructions on how to mix and prepare this hardener and your wood surface for use, check out this video:

However, this epoxy is thin and very easy to apply once you mix it. You can paint this onto wood surfaces effortlessly with a brush, rag, or sponge, but the low viscosity means that it will drip when added to vertical surfaces. You can also mix it with sawdust to create a hardening wood filler.

It soaks deep into the wood and cures relatively quickly. It should be dry to the touch within an hour, but I recommend waiting around 4-6 hours to allow it to set completely.

It adds an extraordinary amount of strength to deteriorated or rotted wood. I’d be confident using this for some load-bearing pieces, but I never recommend using any hardener for structural lumber.

It creates a deep, waterproof seal that will help protect your pieces from ongoing damage. It’s also suitable for outdoor projects and can resist damage from rain and snow.

This hardener goes on clear, and it won’t drastically alter the appearance of the wood. You can confidently use it for spot treatments.

This is “GreenGuard certified” and is a relatively safe hardener. It contains no volatile organic compounds or solvents. It’s more or less odor-free even during application. Still, I recommend wearing gloves, protective glasses, and a face mask while using this product.

Buyer’s Guide

As you can see, every wood hardener is ideal for a different use and can have application and strength limitations based on its viscosity and chemical makeup. Make sure to pay close attention to the below factors when deciding on a wood hardener to purchase to make sure you get the best one for your purposes.

Intended Restoration Surface

The wood you plan to restore often determines which type of wood hardener is best for you. Like the Bondo All-Purpose Putty, thick hardeners are best for when you have large cracks in the surface that need to be filled and restored.

Epoxy hardeners usually have medium viscosity and are best for lightly damaged wood that still has a mostly flat surface. They’re more easily spreadable than putties and are ideal for large, flat surfaces. They also are less likely to drip than thinner options, making them better for vertical surfaces.

Water-based hardeners are very thin and can be ideal for heavily damaged wood. These will soak quickly over rough, uneven, rotted surfaces and penetrate deep into the wood to provide strength. They are the least convenient to use on vertical surfaces because they are likely to drip.

Dry Time

The longer it takes for a wood hardener to dry, the less convenient it is to use. Dry time doesn’t typically affect the overall strength of the hardener, but a quick-drying compound can make for a fast restoration job and requires less waiting around on your part.

Treated Wood Appearance

Many hardeners change the appearance of the treated surface. Some have a more significant effect than others and can darken the wood or make it look glossy.

If you plan to use a wood hardener on certain portions of a project that will be visible, it’s best to opt for one that doesn’t change how your wood looks.

The change in appearance isn’t as much of an issue, of course, if you plan to paint over it or treat your entire project.

Cost

The cost of a hardener may push it outside of your budget, but you should also consider the amount of the product you get for the money. Some hardeners, like the J-B Weld 50151 WoodWeld, are affordable but come in a very small quantity. It’s ideal for small applications but will be prohibitively expensive for larger jobs.

It will be best if you balance the cost of the hardener you’re considering with the quantity you get and the size of the surface you plan to treat.

Strength & Durability

The strength and stability the wood hardener adds to your wood can be a significant determining factor in which product you choose. All wood hardeners don’t offer the same strength to decaying or rotting wood.

If your wood will bear any weight, I strongly recommend the Minwax 41700000 High Performance Wood Hardener. No wood hardener should be relied on to add structural stability, but this is the one I’d choose if I had to for that kind of strength. It creates a deep, solid bond that I feel make damaged wood harder than when it was new.

You should consider the durability of the hardener as well, especially if your project will be outside. Most hardeners will last for many years, but some aren’t waterproof and won’t add much longevity to outdoor projects like decks, window frames, or yard furniture.

A Strong Recommendation When Using Wood Hardeners

Wood hardeners often include potentially dangerous chemicals that should not come in contact with your skin or eyes. Many have harmful vapors that shouldn’t be breathed in during application.

I very strongly recommend that you take every precaution possible to maintain a safe work environment. When feasible, apply wood hardeners outdoors. If you have to use them inside, only apply in a well-ventilated area.

Always wear rubber gloves when using hardeners. Don’t rely on latex, as the compounds can eat through it.

Never use wood hardeners without a face mask or, better yet, a respirator.

Another Recommendation for Use

I recommend you purchase a can of acetone along with your wood hardener. Acetone will help clean any brush you use with wood hardeners so that you can reuse them for future projects.

How to Apply Wood Hardener

There are several key steps to take when using a wood hardener to get the best results possible.

Preparing Your Wood

Start by cleaning any wood you plan to treat. The cleaning process should include stripping away paint and removing dirt, grease, oil, or other contaminants from the surface. Use a powerwasher or metal brush to clear away any loose pieces of wood.

Before you begin applying the hardener, ensure that the wood is thoroughly dry.

Time to Apply

Wood hardener can cure rapidly, so work quickly to apply it to your surface as smoothly and evenly as possible. Take care to avoid globs if you’re working with thicker hardeners.

Once the surface is covered, let it dry in a ventilated area according to the instructions. Some hardeners take several days to cure fully, but most will be dry to the touch within 24 hours.

Aftercare to Ensure Longevity

You can apply a second coat to badly damaged wood once the first application has cured thoroughly. If you used a non-waterproof hardener, make sure your project isn’t exposed to outdoor conditions or high moisture levels.

It’s possible to paint over some hardeners. If you intend to paint your project, use enamel or latex paint to add more protection over the hardened wood. Make sure to use waterproof, outdoor paint if your wood will remain uncovered outside.

Check out this video for an instructional guide on how to apply and cure your wood hardener:

Wrapping Up: My Favorite Wood Hardener

Choosing a wood hardener isn’t as simple as picking the most affordable option. The one you decide on should be designed to provide the strength you need and stand up to the conditions your piece will face in the future, whether it remains indoors or outdoors.

While no wood hardener is ideal for every situation, my favorite product is the Minwax 41700000 High Performance Wood Hardener. It provides incredible strength, brings out the grain of your wood, and will remain waterproof and protective for years to come.

Frequently Asked Questions

What Is The Difference Between Wood Filler And Wood Hardener?

You’d be forgiven for thinking that wood filler and hardener do the same thing. But actually, there are subtle differences.

Wood filler is used to fill up openings, damages and also deep grooves and scrapes in the wood. The wood filler makes the surface smooth.

Wood hardener, on the other hand, works to prevent the wood from suffering and developing new scrapes and dents. It attaches to the wood filler and makes it stick soundly to the wood.

Instead of costly substitutes and also labor, you can add Wood Hardener in order to preserve the wood. The consistency ends up feeling like a soft sponge.

Additionally, if you use a high-quality wood filler, it can permanently repair damaged wood.

Wood hardeners contain chemical substances and are mostly used by tradesmen to strengthen the structural integrity of wood that is old or fragile.

The product seeps into the wood and works its magic on the fibers deep in the wood while protecting them against issues such as moisture which can wreak havoc on the fibers.

Wood fillers are good for reinforcing rotten woods or softwood, however, if you fail to use hardener this solution will be short-lived. How should you use it?

Apply the wood filler gently to the hole with a knife. Press it into the area until it fits tightly. Repeat the layers of putty in thin coats to enable it to dry quickly.

Do I Need A Wood Hardener?

When it comes to reconditioning your damaged fencing or wooden framework that has been exposed to all weather outside, you should definitely use wood harder.

You can greatly increase the life of your outside wooden structures by using a high-quality hardener that seals the surface and offers more durability.

The most convenient as well as most effective means to reinforce timber is to use a hardener. … However, timber hardeners work best in wood that isn’t new.

However, if the wood is already rotten or too soft, the hardener won’t be as effective. What about a small amount of rot?

The wood hardener works well if the rot has only just set in. Once the harder is dry, it can add substantial strength to the deteriorated timber fibers. Using this milky fluid is the best way to address wood rot in its early stages.

How is it done? Firstly, prepare the wood by sanding etc. and add the stain. Add the wood hardener last and avoid sanding after it’s been applied, or the wood will once again be exposed to the elements.

Preserving wood is a good way to enjoy many years of construction and ensure that wood doesn’t get damaged and therefore unusable.

Thank you for this article. I am repainting the wooden columns on my porch. These are Doric columns made of tongue and groove barrel-like staves. There is a very small amount of rot on 2 of the boards each on a different column. Otherwise, the wood is in excellent shape. Since each column is open, I plan to put a support jack in each so they will not be weight-bearing. I would love to have these done professionally but, because we are in a remote area, professionals are hard to find, and paying for travel and lodging is too expensive. At some point, someone filled every seam with caulk. This really caused problems with the paint. I have removed the caulk. Do I need to glue the seams and, if so, what product do you recommend? I have some woodworking experience but not enough to match the shape of the rounded boards to replace the rotted pieces. I know that is what should be done. Thank you so much for any help you can give me. Jan