Contents

Woodworkers often use epoxy resins to give wooden bar counters or tabletops a high-quality, glossy coating. They are also widely used by talented craftsmen and women who use epoxy resin to create the most amazing wooden art pieces like river tables.

This article will take you through each of the best epoxy resins for wood the market offers and discuss their pros and cons.

If you’re on the lookout for an epoxy resin for your woodworking project but don’t have the time to read this entire article, here are the most important things to consider when shopping for epoxy:

- How long it takes to cure: It shouldn’t cure too slowly, or your project will take ages to finish. But it also shouldn’t cure too quickly; it needs to give you time to apply it everywhere (especially on big projects) and make adjustments if needed.

- Product quality: Is the resin crystal clear? Do the bubbles go away easily? Does it create a lot of amine blush? How hard is it once cured?

- Environmental endurance: Depending on your project, you may need your epoxy resin to be UV-resistant, heat-resistant, food-safe, VOC-free, etc.

And here is our Top 3:

If you want to know more, here’s our full Epoxy Resin for Wood Buyer’s Guide:

We’ll kick this list off with a reliable choice from ProMarine. ProMarine’s clear tabletop epoxy resin is ideal for even the hardest-wearing surfaces. Whether it be a bar countertop or river table, ProMarine’s epoxy resin will leave your wood looking crystal clear.

Like many wood-working resins, Pro Marine is self-leveling, which means you won’t have much trouble getting a consistently smooth surface when using it. This is another feature that makes this epoxy resin an excellent choice for beginners, along with the fact that the product behaves very consistently.

For the artistically minded, this resin works well with dyes or other pigments to make beautiful, vibrant coatings over wooden objects like skateboards, tables, or coasters

While this resin is predominantly used on wood, it offers more than enough versatility to be used with other materials too. You can apply it to virtually any surface.

The clear tabletop resin is made from a mixture containing 100% solids. As a result, it also boasts impressive color stability and air release. Meeting FDA guidelines, preparing food on a surface coated in this resin will never be an issue either.

It can take up to 72 hours to cure, and as such, is not the best choice for casting very large objects, as the middle may not cure as fast as the outer layers. However, this product is great for river tables and countertops since it’s completely food-safe once cured.

Also available at: Promarinesupplies.com

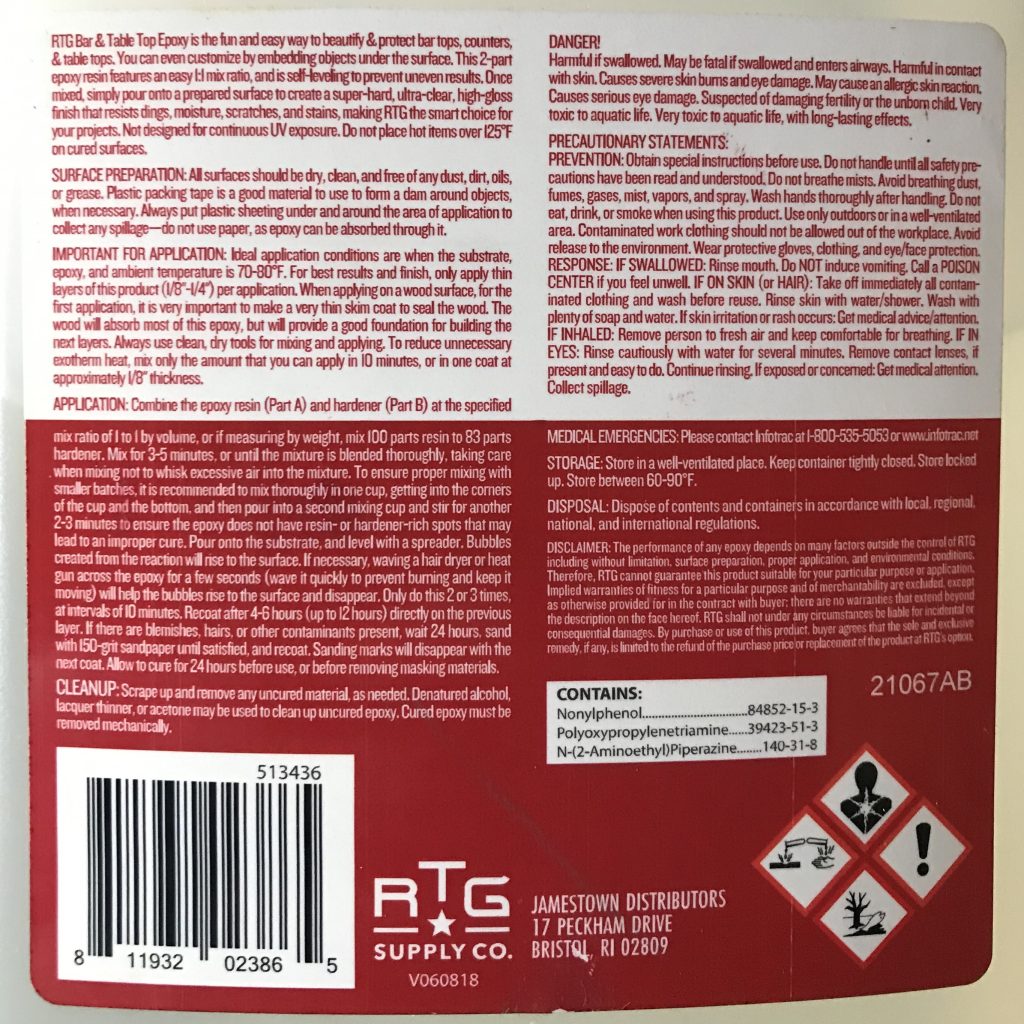

RTG Bar & Table Top Epoxy Resin

Their two-part formula comes in bottles containing 1 gallon of epoxy resin. This is more than enough to get most projects complete.

Your finished project will be resistant to scratches, stains, and moisture. The resin is protected against amide blush as well, so it won’t turn yellow as some lower-quality products do.

This Resin has a fast curing time which means you can apply it in multiple layers to get a thick seal over your wooden surface. As such, you can slowly build up the layers of RTG to create items that are thicker than the maximum pour depth of 1/8 in. One trick you can do is to place a small object between the layers so that once the resin cures, it will appear as though they are floating.

One thing worth knowing about this product is that the fast drying time means you will need to be quick when manipulating it. This makes it a difficult product to use for beginners who may want a resin that gives them a bit more time for leveling and removing air bubbles. However, this may not be too much of an issue since this resin is self-leveling and won’t require much effort to get a perfectly smooth surface.

Due to its fast hardening time, it is not recommended to use RTG for casting large objects. If you do want to do this, you will have to increase the size of your cast incrementally, which can be quite difficult to do. It is important to note that while this resin hardens fast, it is still worth waiting at least 24 hours to ensure it has been fully cured

We were very impressed with this, as it is something not many resin brands offer. The only negative we could find with the resin is that it isn’t intended for outside use as it can’t cope with hot temperatures.

Incredible Solutions 2 Gallon Table Top & Bar Epoxy Resin

This epoxy resin cures very fast, meaning you can easily apply it in layers to create wonderful 3D effects. If you wait longer than 12 hours to apply a second coat, then the first layer will have already hardened, however, this is easily overcome by lightly sanding the original coat. This isn’t the best epoxy resin for making large or deep casts, since it only has a maximum pour depth of 1/8″.

While it will still take up to 7 days to completely cure, (which is standard for most epoxy resins), this product will be hard to touch after only 12 hours. It is blemish resistant, which means that you may not have to worry about removing Amine blush from this product. That said, you may still get a small amount of blush when working with this product at a low temperature below 77 °F.

As well as being resistant to UV and water, this resin produces practically no odor or VOC, which means it is very safe to work with. It also produces minimal bubbles while it is hardening, which means you won’t have to spend as much time with a hairdryer getting air out of your coating.

While this epoxy resin is food-safe once fully cured, it is not a high heat product, which means you should always use coasters or heatproof mats when placing hot cups or plates on it.

Also available at: Incrediblesolutionsonline.com

MAS Table Top Pro Epoxy Resin

MAS is a professional product that is still very easy to use for beginners. It cures reasonably fast and, at the right temperature, will be hard to touch after 8 hours. However, it is recommended to wait at least a full day before sanding and adding subsequent coats, especially when working with deep pours.

That said, this resin can be applied in layers as thick as 1/4″, which makes it a good product for artistic projects like river tables. While it isn’t a self-leveling resin like many of the others we have looked at, it comes with a plastic spreader and foam brush to help you get an even coating. This resin is compatible with most dyes or pigments and is therefore suitable for those who want to create artistic finishes for their tables or countertops.

After coating your wooden tabletop or bar counter in this epoxy resin, you can expect vibrant, smooth results with solid resistance from general wear and tear, scratching, and scuffing. We have the resin’s high gloss formula to thank for that.

One issue with this product is that it is very heat sensitive, and, therefore, will go yellow and soft when exposed to objects above a certain temperature. As such, if you want to use it to seal a dining room table, you will need to use a heatproof mat for placing hot dishes or cups on this resin. Aside from this, though, you can rely on MAS to create a durable and long-lasting coating for any surface in your home.

Also available at: Maxepoxies.com

TotalBoat Epoxy

If you need a solid indoor epoxy resin that can be used for a wide range of projects, this epoxy from TotalBoat is your best option.

The fact this resin is ideal for indoor use may surprise you, considering it comes from TotalBoat – a brand that specializes in working with outdoor water products. However, it is what it is.

When we reviewed TotalBoat’s epoxy resin, we were thrilled with what we found. For starters, we would consider this resin to be top-tier.

Despite its cheaper price tag, it easily competes with the more expensive brands of resin. Secondly, it is incredibly versatile. No matter what your project is, you can all but guarantee that this resin will work.

Finally, this epoxy resin offers unparalleled resistance to a variety of factors that would cause major problems with other resin products. When it comes to resistance, the most impressive thing about this epoxy is that it is 100% waterproof. That is more than we can say for any other resin on this list.

We also found this formula to be one of the best at preventing bubbles and blushes. Overall, there’s nothing we don’t like about this epoxy resin. We love how it finishes a beautiful tabletop.

Also available at: Totalboat.com

East Coast Epoxy Resin

You might not have heard of this brand of epoxy resin, but if you want a fast-curing, budget-friendly epoxy resin, they offer the perfect product for you.

It is clear that East Coast Resin has carefully thought about the essentials of an epoxy resin. They’ve then put all of that into a reliable, effective resin.

In terms of speed, this epoxy resin is tough to beat, offering the user a 30-minute drying time and a cure time of up to 20 hours. For context, that is a whopping 52 hours less than ProMarine’s clear tabletop epoxy resin.

This fast curing time is the resin’s most significant selling point. However, that’s not all. The East Coast epoxy resin also offers high levels of UV protection, water resistance, self-leveling, a high gloss finish, and no odor.

Together, these factors make this epoxy resin one of the best on the market.

The only downside we could find with this resin is that the application process can be tricky. If you don’t prepare your resin correctly, there is a high chance you might end up with bubbles in your final finish.

Also available at: Eastcoastresin.com

Epox-It 80 Clear Epoxy Resin For Wood

If you’re looking for the easiest epoxy resin to use on a wooden tabletop or bar top, Epox-It 80 clear epoxy resin is probably your best option.

Made in the United States with fresh resin, this epoxy formula protects your surfaces from water, UV lights, and blushing.

It produces a crystal-like clear finish that is also very impact-resistant, making it perfect for busy areas like a bar.

As if that wasn’t enough, this resin is also odorless, eco-friendly, and food-safe.

With a working time of 45 minutes, you can work with larger objects without difficulty.

While the most popular of these installations are bar tops and tabletops, you can also use this epoxy resin with no problems when making a river table, art piece, and jewelry.

Also available at: Specialityresin.com

ArtResin Epoxy Resin

Next, we have the epoxy resin manufactured by ArtResin. If you haven’t already guessed, this epoxy resin is for artists.

If you want to create wooden table tops or wooden sculptures, this could well be the resin for you.

This resin doesn’t only work with wood, so if you need an art resin that offers versatility for a wide range of art projects, this one is a great choice.

Perfect for 3-dimensional art, ArtResin has formulated this product to be very easy to cast, which means it will offer accuracy and control over the resin.

The formula is also self-leveling so creating that smooth, glossy appearance isn’t too difficult either.

In terms of safety and durability, this epoxy resin performs quite well. It is certified food-safe, non-toxic, non-flammable, and contains no fumes or BPA.

Regarding durability, this strong epoxy resin resists yellowing and offers UV protection. This will ensure your masterpiece stays perfect for years to come.

We were pleased with most aspects of this product, except its price–it’s pretty expensive.

Also available at: Artresin.com

Magic Resin Deep Pour Epoxy Resin

Manufactured by Magic Resin, the Deep Pour Epoxy Resin provides all we should expect from a high-quality product: It is

- strong,

- durable,

- clear,

- shiny,

- food-safe,

- U.V.-resistant

- scratching-resistant,

- blushing-resistant,

- bubble-free,

- VOC-free

- and water-proof!

You can deep pour this epoxy up to 2 inches, which makes it ideal for river tables. If you need more than 2 inches, you need to pour multiple layers. There are 2 ways to do this while ensuring adhesion between the layers:

- Leave a layer to dry for 18 to 24 hours before pouring the next–no more, no less.

- Let the layer cure for 72 hours, and sand it before applying the next.

Because it is a low-viscosity epoxy, you will easily achieve a bubble-free result, making it great for beginners who never worked with epoxy before. Low viscosity also means it will fill every small crevice.

Its mixing ratio is 2:1. For every measurement of hardener you add, you pour in twice as much resin. After you mix the two components, you have an hour to apply the resin. It will take 48 hours to dry and 72 hours to reach its maximal strength, so make sure you can leave whatever you’re working on for this long.

One more thing: this product is made in the U.S.

Also available at: Magicresin.com

Art ‘N Glow Epoxy Resin

It’s important to note that this resin won’t glow in the dark right from the bucket. You need to add the Glow in the Dark Paint from the same brand to get this magical effect.

As you can probably already tell from its name, this epoxy resin was designed with art in mind. It could easily be argued that this is the best resin on the market for artistic expression.

If you produce artwork using resin, be sure to check this epoxy resin out!

Another clear epoxy resin, the Art’ N Glow resin, delivers on its name. Making life super easy, this resin will help you take your wooden art pieces to a new level. It’s easy to apply, dries hard, and works well with a wide range of materials.

What else does any budding artist need?

Even though Art’ N Glow has designed this resin with woodwork in mind, it can also be used when working with rock, paper, canvas, stone, granite, ceramic, and concrete. This makes it an even better option for artists that work with a variety of different materials.

You could easily use the resin to coat resin paintings, countertops, tabletops, bar stools, and jewelry. If you like making more unique creations, why not use it to make figurines?

When we reviewed this resin, we loved how it can be used to make glowing pieces. We also loved how easily it can be colored using pearl powder.

Superclear Premium Epoxy by FGCI

Superclear is advertised as an art resin; as such, you can use it for projects that require a deeper pour, such as river tables. This means that it works well with pigments and other coloring agents to create vibrant and intricate patterns. Its self-leveling properties and fast hardening time make it highly suitable for sealing tables, countertops, and other wooden surfaces.

As its name suggests, this resin is crystal clear and can be used for casting objects and preserving them in translucent blocks. It also prevents any colors you add from becoming distorted or lost as the resin cures. Once it has fully cured, the product has high UV resistance, which means it won’t gradually turn yellow in sunlight.

Superclear is a mass-dependent product, which means you shouldn’t mix up more than half a gallon at any one time. If you do, the reaction between the resin and the hardener will generate heat, causing it to cure faster and giving you less time to manipulate and work with it.

Remember to always wear a respirator when working with this product, as it does produce volatile organic compounds (VOCs) once the reaction between the two components begins.

Also available at SuperEpoxySystems

Stone Coat Countertops Epoxy Resin Kit

The Stone Coat Epoxy is great for wooden kitchen counters because it is heat-resistant up to 470°F, but don’t leave a very hot plate on it, as it’s only for “incidental contact”.

This product takes a very long time to fully cure, and as such is not appropriate for deep casts that are more than 1/8 inches in thickness. As such, it isn’t the best for more artistic projects and will work best for sealing surfaces. It forms a crystal clear gloss that will show up the grain of your hardwood floor beautifully.

Zdspoxy Crystal Clear Epoxy Resin

The final epoxy resin on this list is the crystal clear epoxy resin from Zdspoxy. Available at an amazing price, this epoxy resin is both affordable and reliable. It also happens to be one of the best epoxy resins on the market regarding self-leveling.

More often than not, manufacturers hype up the self-leveling properties of their epoxy resins. From what we’ve seen, this isn’t the case with Zdspoxy. Promising total coverage when applied properly, we found the self-leveling properties of this epoxy resin worked perfectly.

Thanks to these self-leveling properties, the resin left us with a smooth, rather unique finish. Made in Germany, this resin is of high quality. It has no odor, produces no smoke, contains no VOC, and continuously offers consistently good performance.

We love the clear, glossy finish it provides. We found that the finish gave the wood a shine but still showed off its natural grain.

As if that wasn’t enough, the Zdspoxy epoxy resin is resistant to blushing, bubbles, water, scratching, heat, UV rays, and yellowing. This makes the resin one of the most resistant on the market.

To well and truly top things off, the Zdspoxy resin offers strong adhesion and a more eco-friendly formula.

Buyer’s Guide

When making a final decision in regards to which epoxy resin you need to buy, there are a number of key things to take into account. For example, you need to take curing time and durability into consideration.

If you don’t take key factors like this into consideration, you could quite easily buy an epoxy resin that doesn’t suit the type of project you plan on completing.

To make sure you don’t buy the wrong epoxy resin, we’ve put together a small buyer’s guide. In this buyer’s guide, you’ll find everything you need to know about each important factor.

Durability

Apart from making tabletops, art projects, and bar counters look incredibly beautiful, epoxy resins are designed to make materials more durable and resistant to scratches, punctures, fading, and rotting.

Therefore, it is important to find an epoxy resin that offers reliable and strong durability features. You can see how well a resin performs in relation to durability by simply reading the product description and other user reviews.

Usually, epoxy resins that are thick, offer UV protection, and water resistance, and also have scratch-resistant features are the best resins to look at. These features guarantee durability.

Even if you aren’t buying an epoxy resin for its durability and simply want to make an art project look more unique, you should still always look for a resin that’s both durable and strong. It only makes sense as you probably won’t have to spend any extra money and will be left with an art project that will last a lifetime.

Viscosity

If you’re new to working with epoxy resin there’s a fair chance you won’t know much about viscosity. If you’re experienced when it comes to working with epoxy resin, you should at least have some knowledge about what viscosity is and how it affects things.

For those that don’t know, viscosity is the scientific way of describing the thickness of a gel substance or liquid. Epoxy resin sits somewhere between both of those things. In terms of where it sits on the spectrum, this will vary from product to product.

The reason viscosity varies from product to product is because manufacturers produce a wide range of epoxy resins for different jobs. There is no one size fits all. A high viscosity epoxy resin will be much thicker than a low viscosity epoxy resin.

With that in mind, you need to choose an epoxy resin that has the right thickness for your project.

If you were to choose a thicker epoxy resin, you’ll be left with a resin that is shinier and richer in appearance. You also won’t be able to finish your project as quickly.

If you were to layer this resin too quickly, it will be hard for the air bubbles to escape before the resin dries. You should never add more than 1 centimeter of high viscosity epoxy resin at a time.

If you were to choose a thinner resin instead, you won’t be left with the same visual effects. This isn’t necessarily a bad thing as you might seek a more natural finish.

You can also add thicker layers when working with a lower viscosity resin. This will keep overall work time down.

Drying Time

Drying time is incredibly important when it comes to finding the best epoxy resin for your project. An epoxy resin’s drying time is essentially a measure of your overall working time.

Because epoxies vary so much and use such a wide range of hardeners, their drying times also vary massively.

When picking the best product for your project, you need to think about how much time you have and how much time you’ll need.

For example, if you’re working on something quite artistic like a river table, you’ll probably benefit more from an epoxy resin with a longer drying time.

This will give you more time to work with the material and manipulate it. For simpler projects that don’t require too much shaping etc, you’re going to benefit more from an epoxy resin that dries a lot quicker.

On top of that, you also need to think about the shape of your project. If you’re working on an object that has a semi-vertical or vertical plane, shorter drying times are essential. Without a short drying time, the epoxy resin will run and drip.

Curing Time

Like drying time, curing time is also super important because it impacts how long it takes for the epoxy resin to be fully set.

Epoxy resins with a longer cure time take longer to set which isn’t great if you need to get the task done quickly. However, they are also workable for longer which might suit artists who need to work with the resin more accurately.

If you simply want to pour the resin on, smooth it out, and wait for it to cure, we recommend choosing a resin that sets quickly. Some resins are capable of drying after 20 hours, while others take up to 72 hours to dry.

With this in mind, think about how much time you have to get the project done and what you need from the epoxy resin.

One thing we will say is that epoxy resins with a longer cure time do have more chance of accumulating dirt and dust before they set.

It is also important to remember the three different types of curing times. We’ve listed these for you below:

The first type of curing time is how long it takes for your epoxy to harden to the point where it can be touched.

The next curing time is the length of time you need to wait until you can apply another coat.

Finally, the third type of curing time is the amount of time it takes before the coated surface can be used for any purpose.

Toxicity

For obvious reasons, it is important to determine how toxic any product is before you use it. This is also the case with epoxy resins.

When picking the epoxy resin that suits your project best, not only should you look at how quick it dries and how thick it is, but you should also look at the product’s toxicity.

How important this is to you will depend on your project. Therefore, you need to consider how the end product will be used. The reason for this is pretty simple.

If your project is an art installation, its toxicity isn’t as important as it is if your project is a kitchen countertop. This is because things like cutting boards, river tables, and countertops have to be food-safe.

If people are going to eat from an epoxy resin surface or prepare food on one, it needs to be perfectly safe and free from any toxins and chemicals. You can easily identify a food-safe epoxy resin by reading the label. The label should state whether the resin is food-safe or not.

You can also keep an eye out for certain ingredients. For example, most epoxies are made using Epichlorohydrin and Bisphenol-A. Both of these substances aren’t safe. Epichlorohydrin is even toxic. There are a number of health concerns associated with the use of Bisphenol-A in food products.

You should also avoid epoxy resins that contain carbolic acid. This is a substance commonly used in weedkillers. For obvious reasons, you don’t want this near your food.

Aside from a food-grade safe label, we also advise looking out for a BPA product.

Yellowing

One of the biggest concerns people have with epoxy is yellowing. This is a particularly major concern for individuals that use epoxy resin for artistic projects. Despite most manufacturers focusing heavily on producing clear epoxy resins that don’t have any color, not every resin will stay that way.

Unfortunately, it isn’t uncommon for most epoxy resins to start yellowing. In fact, over time, virtually every epoxy resin will start to yellow. Whilst this is extremely frustrating, by purchasing the best epoxy resin we can avoid this from happening too soon if not altogether.

Like most things, if an epoxy resin isn’t made to a high standard it won’t last as long. You may even find product reviews stating that yellowing occurred almost immediately. Sadly, this is something manufacturers will try to cover up.

Some manufacturers will even claim that their epoxy resin uses a “non-yellowing formula”, when in fact they don’t.

Taking this into account is very important when making your purchase. Before making any purchase, you should first carefully read product reviews. If there is a yellowing problem with that specific resin, it will soon become clear to you.

It’s worth noting that yellowing might not be a problem for you. If you only need an epoxy resin for a repair project, the yellowing might not even be visible once the resin has dried and cured. If appearance is a non-issue, don’t worry about this.

Protections

While the vast majority of epoxy resins are durable and strong, there are still a handful of epoxy resins that simply don’t offer enough protection. If you want an epoxy resin to protect something and make it more durable, you seriously need to think about just how much protection the resin will offer.

Generally speaking, most epoxy resins work well, giving us more than enough protection to keep our furniture, flooring, countertops, and art projects safe from superficial damage and impact. These are the epoxy resins that steal the headlines. Picking one of these resins out will ensure your materials last longer.

The reason these epoxies are so good is that they have been designed to offer protection against a range of different things. For example, most effective epoxy resins offer protection against general wear and tear, UV radiation, and the elements.

These are the types of protection you should keep an eye out for when choosing the best epoxy for your project. If you don’t see the protections an epoxy resin provides in the product description, we advise looking elsewhere.

As a minimum, you should pick a resin that can offer protection against extreme heat, extreme cold, water, UV radiation, and of course, general wear and tear.

Water Resistance

If you need an epoxy resin to guarantee the durability and shelf-life of your wooden furniture, DIY projects, or art projects you have to make sure it has water-resistant features. If the epoxy resin you choose doesn’t have good water-resistant features, water will seep through the resin and into your wood.

As you probably already know, this will seriously damage the wood, massively reducing its shelf-life in the process.

Thankfully, finding an epoxy resin that offers great water resistance isn’t that difficult. Like most plasticized substances, epoxies are naturally good at repelling water.

It is quite uncommon for any epoxy resin to be vulnerable to water. However, they aren’t always waterproof. A lot of epoxy resins are just water-resistant and not waterproof.

This often leaves people feeling disappointed when they find that a glass of water has left a mark on their new shiny epoxy resin finish.

While this won’t be an issue that affects everyone if you plan on exposing your epoxy resin to moisture you have to ensure it’s waterproof too. All you have to do to find out if a resin is waterproof or not is check the label. The label will tell you if the epoxy resin is waterproof or not.

UV Resistance

Having an epoxy resin that offers protection against UV rays might not be something everyone needs but it is still very important. If you plan on leaving your epoxy resin finished project outside, this is even more important.

Over time, UV light rays from the sun cause epoxide substances to break down. In all honesty, this can take a very long time and does vary depending on the climate you live in, however, if you want something to last for many years, you need to find a reliable epoxy resin that has UV-resistant properties.

The main problem caused by an epoxy resin that doesn’t offer protection against UV light rays is yellowing. UV radiation causes clear epoxy to change color. It will start to turn yellow and may gradually cloud over too.

This yellowing is the biggest sign that the resin has started to break down. Despite taking a while to fully break, this molecular collapse will leave your wooden surface exposed and vulnerable to the elements.

Most epoxy resins you find on the market will offer some form of protection against UV radiation so finding one shouldn’t be too hard. Having said that, it’s always a good idea to look for the best.

If you read product descriptions and reviews carefully, you will even find epoxy resins that cure when exposed to UV light.

Self-Leveling

When scouring the market for the best epoxy resin for wood, there’s a pretty good chance you’ll come across resins advertised and described as “self-leveling”. If you haven’t worked with a variety of epoxy resins before you probably won’t have a clue what this means.

The fact manufacturers don’t typically explain what it is either doesn’t help matters. No need to worry though, that’s why we’re here to help.

An epoxy resin described as self-leveling means that its chemical structure is perfect for level structures.

In other words, it means the epoxy resin can create a level surface without you having to put in any extra effort. However, in reality, things aren’t normally that easy. Most self-leveling epoxies still require brushstrokes to form a flat, even surface.

They are still very good for helping users get that smooth shiny finish though so if you need to create a shiny, smooth finish and don’t want to do too much, make sure you buy a resin with this feature.

We’d even go as far as saying that it is an essential feature you need from any epoxy resin. Arguably, there isn’t a single project self-leveling can’t help with. One thing we will say though is that you shouldn’t expect a formula to be able to cure quickly and self-level at the same time, even if that’s what’s advertised.

Blush

Blush is one of the more frustrating factors you might have to deal with when working with an epoxy resin. The main reason for this is that it doesn’t usually appear until the curing process is already well underway. By this time, there isn’t much you can do about it.

When an epoxy resin blushes, it produces a waxy bi-product. This waxy bi-product then sits on top of the surface of the resin.

Blushing causes a number of problems. First of all, epoxy resin blushing spoils the finish. It gives the resin a different appearance and one none of us want.

Secondly, it makes it much harder to work with the project. Once blushing has occurred, adding an extra layer of epoxy or applying another type of finish is almost impossible to do correctly.

In terms of how you can avoid blushing, there’s very little you can do. You could look for an epoxy resin that offers some protection against blushing, but blushing could still occur.

By far the best, and arguably the only way to prevent blushing in your project is to ensure your workspace is as dry as possible. When we say as dry as possible, we mean it! You might even need a dehumidifier.

Bubbles

Once you’ve bought the epoxy resin that suits your project best, there are still plenty of things to think about and deal with. One of the most common things you could come across is bubbles.

Those of you that have worked with epoxy resin and wood before will already know just how much bubbles like to appear in cracks.

Super annoying, bubbles can occur for a number of reasons and in multiple places. Bubbles can appear inside and outside the formula. Either way though, bubbles will completely ruin your project. The epoxy resin finish will look awful.

How you go about dealing with this problem will depend on where the bubbles are coming from. You have to deal with bubbles within a lot differently than those found on the exterior.

If you’ve noticed bubbles seeping into your epoxy from the exterior, you should apply the epoxy in a hotter place with very little or no humidity. If you spot bubbles forming on the interior of the material, you have to use a heat gun to get them out. You could use a blowtorch too.

Like blushing, bubbling will have a bigger impact on formulas that have quicker drying and curing times. Therefore, if you want to avoid this issue, you might choose an epoxy with slower drying and curing times.

At least bubbling is a lot easier to solve than blushing.

Application

How easy an epoxy resin is to apply is always going to be important, no matter who you are. Whether you’re a beginner that’s never worked with epoxy resin before or someone who works with it every day, you’re going to want a resin that can be applied quickly and easily.

Aside from speeding the job up and helping you learn the process, an epoxy resin that is easily applied reduces the chances of any mistakes occurring.

An epoxy resin that is difficult to apply dramatically increases the chances of something going wrong. Most of the time, this leads to the resin not curing correctly.

More often than not, most of these curing problems come from the time it takes for the resin to be applied. A lot of people find that by the time they’ve worked out how to use the resin it’s already started to cure. A messy finish can be expected.

Blushing and bubbles are also common.

Taking all of this into consideration, you should try your best to find an epoxy resin that has an easy application. To find a resin like this, you should read user reviews to see what they thought, read product descriptions, and see what instructions the resin comes with.

Clear, easy-to-follow instructions will make it much easier for you to apply the resin without encountering any issues.

Coverage

The final thing to think about when looking for an epoxy resin for your wood-based project is coverage. Coverage is one of the defining factors when deciding whether or not a resin is right for the job.

At the end of the day, you need an epoxy resin that will cover the whole job. If it doesn’t you will be left short. This will lead to an uneven, incomplete project. There’s even a good chance that you could completely ruin your project by accident.

On the epoxy market, you’ll find products that offer things like “superior coverage”. These products are designed to give you more for your money.

This essentially means that a smaller amount of epoxy resin will cover a wider area. A resin that can do this will save you money, lowering the overall costs of your project.

Seeing as though epoxy resins aren’t the cheapest materials in the world, this can be extremely helpful.

Unfortunately though, some of these claims are false. Most epoxy resins are the same, offering little difference in the form of coverage. As a result, you should carefully check product reviews before making a decision.

If you do find an epoxy resin that covers 12 feet or more per gallon, you’re in luck!

Frequently Asked Questions

What Is Epoxy Resin?

Epoxy resin, otherwise known simply as resin, is a material that has a wide range of uses and purposes. It is created by mixing two components that are matched together.

Also referred to as polyepoxides, epoxy resin is well known for its strong adhesive qualities that make it super versatile. Resistant to heat and chemical applications, epoxy resin is widely regarded as the ideal product for times where a stronghold under pressure is required.

If a resin is mixed with the right hardener, a chemical reaction will take place, usually lasting for several hours. During this process, the material radiates heat and converts from a liquid to a solid. Its final state is known as a cured state.

In terms of what epoxy resins can be used for, things vary depending on the resin’s individual properties. Some of the properties that change from resin to resin include curing time, viscosity, thickness, hardness, and adhesion properties.

Some of the most common uses for epoxy resin include cut-resistant sealing of worktops, decorative objects, quick repairs, modern renovation, tabletop artwork, jewelry, the casting of molds, and timeless resin furniture.

Are Epoxy Resins Dangerous?

Typically, most epoxy resin products and materials can be considered dangerous. Whilst they don’t pose a great threat to people when used correctly, if caution isn’t taken, accidents could happen.

Most epoxy resins are considered dangerous because they are normally classified as hazardous material. More often than not, they are extremely toxic and should only be used in an industrial setting.

With that in mind, an industrial application should be taken. That means anyone working with epoxy resin should wear protective eyewear, hazmat clothing, and heavy-duty respirators.

It is also worth noting that epoxy resins are flammable too.

Exposure to too much epoxy resin over long periods of time can result in an irritated respiratory tract. Sensitive areas like the face and eyelids can also experience swelling and itching.

Can I Use Epoxy As A Wood Sealer?

When conditions are right, epoxy resin can be used with wood in many different ways. The most common of these is to simply show off the wood and present its natural appearance. However, it can also be used to optimize other things.

If you work with the epoxy resin carefully, you can fill gaps and even seal the wood. If you manage to do this correctly, your piece of wood will be protected from moisture and more resistant to mechanical stress.

For the best results when sealing your wood with epoxy resin, you should start by coating the exposed or cracked surface with your prepared resin mixture. Next, apply multiple coats on the wood until all of its porosity is sealed.

It isn’t uncommon to see some grain rising during the coating process. Once applied, you should leave the wood for 24 to 36 hours to give the resin time to cure. Only then should you proceed with what you want to do next.

Can I Use Multiple Layers of Epoxy?

If you’re quite new to the world of epoxy resin, you might not know how many layers of epoxy resin you can coat something with. Don’t worry, this is a common question most people ask themselves at some point.

Generally speaking, you can coat a surface with as many layers of epoxy resin as you want. Most epoxy resin projects will require at least two to four layers. Some projects might require several.

Bearing this in mind, you don’t need to worry too much about how many layers of resin you use. Instead, you need to think about when you’re applying the next layer. To ensure your project has the best finish possible, you have to apply the next coat of resin at a suitable time.

If the epoxy is slightly wet but still cured enough to hold the weight of another coat, you can add a layer to create a ‘primary bond’. If the epoxy has dried, you’ll struggle to create a primary bond. In this instance, you’ll need to achieve a secondary bond.

Do All Epoxies Yellow Over Time?

To put it simply, yes, all epoxies yellow over time. This is a well-known fact and something we can’t do anything about. No matter how you apply the epoxy, after curing, it will start to yellow.

This yellowing might not be very noticeable at first, but it will start to become more and more noticeable as the years go by.

Despite not being able to fully prevent the yellowing of epoxies over time, there are still things we can do to prevent it from happening too quickly. It is also worth knowing that some epoxies might go clear instead of yellow.

Usually, exposure to UV light, moisture, extreme heat, and oxidation speed up discoloration. Therefore, we can slow the process down by reducing how much the epoxies are exposed.

By simply keeping your epoxies away from UV light, in a dry place, and away from extreme heat, you can slow down the yellowing process and preserve your epoxy pieces for longer.

Does Epoxy Bond To Wood?

Yes, epoxy does bond to wood. In fact, the bond between epoxy and wood is incredibly strong and durable.

Valued by professionals and DIYers, epoxy is well-known for its unbelievable strength and long-lasting adhesion.

When applied to wood, epoxy creates a waterproof, durable, super strong seal that isn’t easily broken. This bond is, however, easily sealed, drilled, and sanded. It is the epoxy’s ability to bond with wood that makes it the ideal choice when working with wooden furniture.

Better still, we don’t need to do anything to make the two bond. Simply prepare the epoxy, apply it to the wood, and wait for it to set. Once set, the epoxy will be bonded with your wood.

In numbers, epoxy gives a bond up to 20% – 25% m.c.

Does Epoxy Last Outdoors?

Easily one of the best things about epoxy is its ability to last outdoors. We have its incredible durability to thank for that.

When applied correctly, epoxy can easily last half a lifetime outdoors before you start to see severe changes or experience the need for repairs. Of course, some circumstances impact this so a concrete figure can’t be provided.

For example, epoxy left outdoors in a hot climate won’t last the same amount of time as epoxy left in a cool climate. Taking this into account, you should expect your epoxy to last at least 10 years outside. In those 10 years, you won’t need to worry about replacing anything.

Thanks to epoxies’ ability to survive so well outside, it is a very popular choice with professionals installing pools and patio spaces.

Having said all of this, you do also need to look after your epoxy if you want it to last longer. Improper care could result in damage, which will in turn reduce the lifespan of your epoxy.

Can Epoxy Make Wood Waterproof?

One of the main reasons epoxy is so commonly used is because of its ability to make materials waterproof. Ever since this detail was discovered by the pioneers who made it, epoxy has been used as waterproofing in a wide range of industries.

One of the most common places you will see epoxy being used as waterproofing is in the home construction industry.

Once applied, you can expect it to take approximately 7 days for the epoxy to fully waterproof the wood.

So, how does epoxy waterproof wood? The reason epoxy waterproofs wood is because it binds so well with the surface it’s applied to. As the epoxy then dries, it forms a thick airtight layer. This airtight layer doesn’t allow any space for water to enter.

The adhesive bonds of the epoxy are so strong that it is almost impossible to separate it from the material it has been applied to, stopping water from flowing through. The only time the material might not be waterproof is when the epoxy has cracked. This will give water space to flow.

How Can Epoxy Resins Be Removed?

Epoxy resin can be a tricky material to remove, but don’t worry there are plenty of ways to do so. There are several different ways we can remove epoxy resin from a surface, all of which suit a different type of epoxy resin.

As a result, you might have to try a number of different things to remove your epoxy resin. The popular ways to remove epoxy resin are by using a heat gun, using chemicals, using acetone, or by carefully scraping and sanding the area. There are other methods but these are generally considered the best.

We’ll give you a quick rundown of each one below:

– Scrape or sand the area – If you only need to remove a small area of epoxy resin, you can carefully use a scraper or sandpaper to scrape the resin off. You should exercise caution when removing resin this way because you don’t want to mark your surface.

– Use a heat gun – You can use a heat gun to remove epoxy resin but you must be careful. You should always use thick work gloves, a mask, and goggles when using a heat gun. You should also ensure your skin is completely covered. When ready, use the heat gun at a temperature of 194 °F and target small areas. When the epoxy resin goes soft, remove it with a plastic scraper.

– Use acetone – On concrete and wooden surfaces, acetone can be an effective way to remove epoxy resin. The acetone will make the epoxy resin soft enough to be peeled away effortlessly. However, you should only ever use acetone in well-ventilated areas.

– Use Chemicals – If you need to remove epoxy resin from glass or plastic you can use chemicals to soften the epoxy. Once soft, you can scrape the epoxy resin away. If the resin has only just dried, use a methylated spirit to soak a cloth and wipe the surface. The epoxy should come straight off. For more stubborn, fully-cured resins, try applying a paint thinner.

Is Epoxy Eco-Friendly?

Generally speaking, most epoxies are one of the more environmentally-friendly materials to use when coating furniture, etc.

This is because they come from organic plant sources and are manufactured in a way that doesn’t release any biohazards into the environment. They also don’t tend to contain any contaminants that would put humans in danger.

Having said that, some factors also make epoxy less environmentally friendly. Generally speaking though, how environmentally friendly an epoxy is depends on its specific makeup.

For example, thermoset resins aren’t usually recyclable or biodegradable. This makes them more harmful to the environment when they are disposed of.

There are also epoxy resins that aren’t environmentally friendly because they are made from crude oil through a refining process. This process produces a product that is harmful to plant life, animals, and humans.

If disposed of incorrectly, the air, soil, and water can be polluted.

Of course, epoxies made in this way aren’t sustainable either because crude oil isn’t a renewable resource.

As a result of some epoxies being highly toxic and not environmentally friendly, many alternatives have been looked at. An example of some of these is EcoPoxy and CCR Bioresin.

Is Epoxy Scratch-Resistant?

Yes, epoxy resin is scratch resistant. You’ll find it much harder to scratch epoxy resin than any other material. This is one of the main reasons we use epoxy resin to coat furniture, tables, kitchen tops, and art projects.

This doesn’t mean your epoxy won’t scratch. Despite being extremely scratch resistant, there is still a slight possibility that your epoxy will scratch. Luckily, if your epoxy ever gets scratched, the scratch should be fairly easy to remove.

All it takes to fix a small scratch in an epoxy coating is a rotary tool and a sanding disc.

This can occur because epoxy resins are scratch-resistant but not scratch-proof. This may seem odd, but it’s just how things are. Even though the chances are very slim, you should always use caution when working on an epoxy resin surface if you want to avoid any scratches.

For example, if you’re cutting food on your epoxy resin countertop, you should use a cutting board. You can also use simple things like a trivet to prevent hot pots from sitting directly on

your countertop.

Apart from that, you don’t have much to worry about when it comes to your epoxy scratching.

What Is The “Pot Life” of Epoxy?

When purchasing an epoxy adhesive, it is important to understand everything about the product. You need to know how strong it is, the ratio you should use, the working time, the curing time, and the epoxy’s “pot life”.

You probably already know to look for most of these things, but some people forget to look at the epoxy’s pot life. This is something you need to know!

For those that don’t know what it is, an epoxies pot life is typically defined as “the amount of time it takes for an initial mixed viscosity to double, or quadruple for lower viscosity products (<1000 cps)”.

Essentially, it is the amount of time it takes to apply multiple coatings to a surface. To give you a better understanding, we’ve provided you with an example below.

Example: If a mixed resin has an initial viscosity of 10,000 cps and that viscosity rises to 20,000 cps after approximately 25 minutes, that resins pot life is 25 minutes. Despite seeming quite complicated and hard to understand at first, it is as simple as that.

What Is The Shelf Life of Epoxy?

Compared to most polymers and hardeners, epoxy has a longer shelf life. The standard shelf life of most epoxy products is 3 years for epoxy resins and 2 years for hardeners. However, there are some epoxy products that might only last 18 months.

You can find out how long your epoxies shelf life is by simply reading the manufacturer’s description of the product.

However, just because the manufacturer says the epoxy has a shelf life of 3 years doesn’t necessarily mean it will last that long. That part is up to you. If stored correctly and used properly, your epoxy will last the length of time expected. If you don’t look after the epoxy though, you can expect it to expire much quicker.

For example, if you open an epoxy resin and don’t then store it away correctly, it will probably only have a shelf life of up to 6 months. Once the epoxy has expired, it shouldn’t be used.

How Can You Tell If Epoxy Has Expired?

Time will eventually affect epoxies handling characteristics and cure strength. It is when these effects occur that we can no longer use an epoxy and expect good results. Therefore, it is important to know when your epoxy has expired.

Luckily, the tell-tale signs that an epoxy has expired are pretty easy to spot. For starters, most epoxies will change color. They may turn darker in color until they are red or purple.

Secondly, they might become a lot thicker. It isn’t uncommon for resins to lose clarity and change consistency. They will continue to change consistency until the resin is too thick to work with.

Finally, don’t be surprised when you notice drastic changes in how your epoxy smells. As epoxies expire, they often start to produce a strong odor. If this happens, you can assume your epoxy has expired.

If you notice any of these signs, your epoxy has probably already started to expire. Some signs can be reversed if spotted early but you should always bear in mind that when an epoxy has started to expire, its overall strength and durability will drop.

It’s probably best to simply throw the epoxy out.

What Is The Difference Between Epoxy And Casting Resins?

Technically speaking, there is no difference between epoxy and casting resins because epoxy is a type of resin. However, that doesn’t mean the two don’t have unique properties that make them better for different jobs.

As a result, it is important to choose the right type of resin for your job. Despite there being three types of resin (epoxy, casting, and polyester), only epoxy and casting resins are commonly used in general DIY projects. Polyester resins are more commonly used in the marine industry.

Therefore, more often than not, you’ll be choosing between casting and epoxy resins when completing a job. That’s why it’s so important to know the differences between the two.

So, what are the differences between casting and epoxy resins?

Casting resins are normally a lot thinner and runnier than epoxy resins. This means they also have a lower viscosity. This can be a massive help in some projects but also a massive hindrance in others.

Epoxy resins typically have much faster curing times than casting resins. Most of the time, this is an advantage as it means you don’t have to wait as long for the resin to cure. However, this also means you have to work quicker as you’ll have a shorter period of time to work with the resin.

The viscosity and cure times lead to a thinner pour depth when working with epoxy resin. Usually, epoxy resin will also come with a simpler mix ratio (1:1).

Which Dyes Can I Use To Color My Epoxy Resin?

Epoxy resin normally cures completely clear. While this is perfect for showing off the natural beauty of wooden furniture and kitchen countertops, it’s not always what we want. Particularly in art projects, most people seek a more colorful resin that adds something extra to the piece. That’s where coloring the resin comes in.

One of the great things about epoxy resins is that you can easily use any high concentrated colorant to add plenty of vibrance. This gives you the chance to unleash your creativity and create something unique and exciting.

When it comes to the dyes you can use to color your epoxy resin, as long as the colorant is resin compatible, you can simply choose any colors you like. Just make sure you mix them properly and apply them correctly.

If you don’t want to use a dye and would prefer to use something else, there are plenty of other options you have at your disposal. You can easily use alcohol ink, food coloring, mic powder, acrylic paint, and unbelievably eye shadow to color epoxy resin.

Depending on the size of your job, the product you use to color the resin will change. For example, you wouldn’t use eyeshadow to color a large countertop.

What Epoxy Resin Is Best To Use On Wood?

When it comes to picking the best epoxy resin to use on wood. The final decision isn’t an easy one to make. As you can see from our list, there are many excellent epoxy resins to choose from.

On top of that, everyone’s opinions and preferences are different. Something you might like from an epoxy resin might be completely different from what the next person likes. Therefore, it could be argued that the best epoxy resin for wood is a personal choice that changes from person to person.

However, if we were to base things purely on overall performance and product reliability, we have to say one option stands out to us more than the rest.

For us, ProMarine’s clear tabletop epoxy resin is arguably the best resin you can use on wood. Perfect for the hardest of surfaces, this resin offers reliability, versatility, and a stunning glossy finish. It is also one of the easiest epoxy resins to apply.

How Do You Choose The Best Epoxy?

Even when you think you know everything there is to know about epoxy resins, choosing the best one for your project still isn’t the easiest of things to do. With so many properties to take into consideration, so many brands to choose from, and a wide price range, picking the best option can still take time.

Having said that, by thinking about the right things and carefully working out what you want and expect from a project, you should be able to pick the right type of epoxy for the job.

If you’re not sure what type of epoxy resin to choose, you should start by asking yourself the following questions:

– How long can you afford to wait for the epoxy to cure?

– How thick does the epoxy need to be?

– How hard does the epoxy need to be to withstand the expected impact?

– Do you need a self-leveling epoxy?

– Do you need to suspend your materials in epoxy?

– Do you require a mold or frame to hold the epoxy during the curing process?

– Does the epoxy need any special properties?

– Will the epoxy be exposed to extreme conditions or elements?

By asking yourself these questions and by using our buyer’s guide to help, you should be able to decide which type of epoxy you need to use.

Final Thoughts

There you have it, the best epoxy resins for wood currently on the market. While it can be quite difficult to find the best epoxy resin for your project, when you know what you’re looking for things become a lot easier.

As you can see from the options we have discussed in this article, there is a wide range of different epoxies to choose from. Having said that, we are confident that the options we have shown you are up there with the very best.

The options we have talked about vary in terms of curing times, color, effectiveness, and resistance. However, one thing is guaranteed. They will all leave your wooden table tops, bar counters, and art masterpieces looking absolutely incredible. They’ll also give them plenty of durability and resistance.

With our list of epoxy resins and buyer’s guide at your fingertips, take your time to narrow down your options. If you come across any difficulties, refer to our frequently asked questions section for the answers.

By doing so, you should be able to pick out the epoxy resin that suits your needs and requirements best!

I have termite and rot damage in the core wood of my boat, a Contessa 27. The wood stringers could not be taken out. I was told to inject epoxy using pressure, do you know about this process and how I should proceed?

Hi brand, sorry to hear about your boat 😢

A fried of mine did this a few years ago. It was on an old barn, but his process should work with you as well.

First you should make sure all termites are gone, I assume you already did that, then:

Use the claw back of the hammer to remove all of the damaged and decaying wood.

With a die grinder fitted with a core-box bit, sand down all wood that has been honeycombed and softened by rot.

Use a meter to measure the wood’s moisture content. If the reading is larger than 18, repeat step 3 again.

In the termite-damaged region, drill three holes that are equally spaced and half an inch deep.

Utilizing the syringe, inject the wood preservative into the drilled holes.

The epoxy primer should be applied with a 2-inch latex paintbrush. Utilize paper towels to wipe away any extra primer. Wait until the primer has dried for 15 minutes.

On top of a plastic board, combine the catalyst and epoxy resin. Using a plastic putty knife, stir the two ingredients together.

The epoxy filler can be molded into the termite damage. The epoxy should be shaped to fit the nearby wood.

I want to use epoxy resin to create a river table. The total volume I woud need to pour is around 3 gallons. Could you please tell me how much hardener, what the mixing ratio should be, and what color to use? I might want to add some blue coloring. Could you please tell me the cost of this, including shipping to colorado?

Hi Melissa, most resins have a hardener to resin ratio of 1:1, which means for 1 gallon of resin you need to add 1 gallon of hardener.

So for your project, you would need at least 1 ½ gallon of each, 3 gallons in total. I would recommend getting a total of 4 gallons, just to be sure you have enough.

Good luck on your project!

I’m constructing a plywood bar top with an oak veneer.

The surface will first be covered by a stain, followed by several vinyl stickers and epoxy.

This will be positioned close to a covered deck’s edge where it will receive some sunlight (perhaps 4 hours per day), but not much.

I’m not sure what to buy and would appreciate any suggestions.

The idea of applying to stained wood worries me. I’ll construct the top in my heated garage, apply the resin there, and then install the finished top over the section of the deck railing.

Should I coat the dyed wood and stickers with polyurethane before using epoxy?

Should I coat cured epoxy with UV-inhibited polyurethane?

Any and all advice, guidance, and suggestions would be highly appreciated.