Contents

Screws are common fasteners used to connect and secure objects together. These simple tools serve all sorts of purposes and are used for anything from building a deck to hanging a painting on the wall.

But screws have evolved and diverged into countless variations because of their simplicity and usefulness. If you’ve ever walked into the screw aisle in a hardware store, you’ve undoubtedly been overwhelmed by the sheer volume of different screws available.

Luckily, this guide sheds some light on the various types of screws and when to use them. Here, we’ll take a look at some of the most common varieties of screws, what they are used for, and what makes them different from other screws.

So, let’s get right into it and dive into the world of screws!

What Are Screws?

Screws are one of the most common types of fasteners, but what exactly are they? It can be a bit tricky to understand if you’re unfamiliar with what screws are used for.

Screws are a type of fastener – small tools used to secure two objects together. They may look similar to nails, but their unique design and function set them apart.

While they resemble nails, screws are notable for their spiral-shaped threads and unique heads that have space for a screwdriver or drill bit to drive them into a material.

People use screws for all sorts of purposes, from woodworking to construction, to craft and DIY projects (to list just a few things). The wide variety of screws makes them handy for many different reasons, and some screws are versatile enough to serve multiple purposes.

Parts Of A Screw

Screws are made up of 4 main components. These can vary depending on the type of screw you’re using, so it’s important to ensure you have the right screw for the job.

Here are the parts that make up a screw.

The Head

The head of a screw is the top part where you use a screwdriver or drill. This is one of the most important components of your screw, as it will affect the tools you need and what you can use the screw for.

You need to look for two things in a screw’s head: the drive and the head shape. The drive is the part of the head where you put your drill or screwdriver. There are several types of drive, and some are better than others.

Flathead screws (also known as ‘slotted screws’) have a single line through their diameter. As the name suggests, you need to use a flathead screwdriver to turn these.

Philips head screws are probably the most common. These have a cross-shaped drive, compatible with Philips head screwdrivers and electric drills. Phillips head screws come in various sizes and depths, and it’s easy for the drive to slip or cam out.

Square head screws are less common due to their unusual drive shape, but they are some of the easiest screws to use. The square drive makes drilling much easier and pretty much eliminates the risk of cam-out.

Star (or Torx) screws are similar to Philips head screws but have a star-shaped drive with 6 branches instead of 4. This shape makes it practically impossible for the head to break or cam out, even while using a power drill.

Because they are less common, finding the right driver bit for your drill can be hard. Head shape is also important, although there is less variation here.

Flat head screws might sound confusingly similar to flathead screws, but they just refer to any screw with a flat top regardless of their drive.

Typically, a flat head screw will have a beveled part on the other side of its head that nestles flush into the word (it’s easiest to achieve this if you drill a pilot hole with a countersink drill bit).

Rounded and panhead screws have a convex, domed head that sits raised up from the material you are drilling into. They are usually used for materials that you can’t countersink, such as plastic or metal.

Panhead screws have a fairly shallow dome, while rounded screws have a much deeper one. Again, these only refer to the shape of the head, and you can find any shaped drive here. That said, you’re more likely to find square and star drives in these screws.

The Shank

The shank of a screw refers to the main part of the screw. This is the straight metal part, which has the threading along part or all of its length, and the tip and the head on its ends.

The shank is the main part of the screw. However, there isn’t much variation in screw shanks apart from their length, thickness, and how far up the threads of the screw go.

By leaving the top part of the shank without any threading, the screw is given more strength and stability and is less prone to loosening.

If a screw has no empty shank at all and the threads reach all the way to the head of the screw, it is known as a ‘fully-threaded’ screw.

The Threads

A screw’s threads are the spiraling pieces of metal that allow it to actually screw into place. The threads on a screw can vary depending on the type of screw.

Screw threads can come in plenty of different types. The most common differences in screw threads are their thickness, angle, and density (typically measured in threads per inch, or tip).

The Tip

This is the bottom end of the screw that you stick into the material. Most screws will have a pointed tip that is used to guide the screw into the correct position until the threads begin to drive into the material.

There are a few different types of screw tips.

Most screws have a simple point that either leads into the threads or is combined with the threading into a corkscrew-shaped point.

Self-drilling screws have a split point that looks similar to a drill bit. This taps a hole for the screw as it goes into the wood, removing the need for a pre-drilled hole.

Other screws, such as machine screws, have no point at all. These thick screws are more similar to bolts than regular screws; however, they have a head that lets them be driven in with a screwdriver.

Types Of Screws And Their Uses

Now that you know the parts that make up a screw and how they can vary, it’s time to look at the different types of screws and how to use them.

There are far too many types of screws to cover in one article, so these are just some of the most common varieties of screws you’re likely to encounter during DIY projects.

Wood Screws

The simple wood screw is one of the easiest kinds of screws to find, and they are available at practically every hardware or DIY store out there.

Wood screws are used to fix two pieces of wood together. Their design is as simple as their purpose, although their popularity stems from how specialized they are for their job.

A standard wood screw has a flat head with a Philips or flathead drive that tapers into the shank. The shank is partially threaded and has a small smooth section at the top. Most wood screws have a standard, pointed tip that needs a pilot hole drilled beforehand.

As the name implies, wood screws are the most commonly used screw for woodworking. They work especially well if you drill a pilot hole in the wood with a countersink drill bit.

This creates an angled hole in the wood for the screw’s beveled head to nestle into, which improves the screw’s stability and leaves the head level with the wood’s surface.

Deck Screws

Deck screws are very similar to wood screws. However, some key differences set the two apart.

Because they are primarily used to attach pieces of decking together, deck screws tend to be much longer than standard wood screws. This includes a longer, smooth section of the shank, which helps the pieces of decking stay secure and strong.

Deck screws are also usually self-tapping, which means it bores their own pilot hole. Because of this, you don’t need to drill the pilot hole beforehand and can get straight to screwing.

Deck screws are coated in an anti-corrosive finish to help them endure the elements in external use. They also tend to be stronger and are made of hardened steel.

These factors make them perfectly suited for fastening larger pieces of hardwood, both internally and externally.

Drywall Screws

Drywall screws are a specialized type of screw used to attach drywall sheets to wall studs with minimum damage. They are also frequently used in woodworking, as they are easy to find and usually cheaper than wood screws.

Because of their purpose, drywall screws have a very specific design.

While their heads have a flat top like wood screws, they abandon the tapered head for a more trumpet- or bugle-shaped head. This reduces the damage to the exterior of the drywall while countersinking without needing a drill.

They have very hard, self-tapping tips. This lets the screw burrow deep into the drywall and the stud behind it without needing a messy pilot hole.

Unlike wood screws, the entire shank of a drywall screw is threaded.

Drywall screws are much thinner than wood screws to reduce the damage to your drywall. However, this makes them very brittle and prone to snapping, especially if you’re drilling them into hardwood studs.

Sheet Metal Screws

A sheet metal screw has a completely different purpose than the other screws we’ve looked at so far. As a result, it’s only fair that their design is different too.

Sheet metal screws are used to attach thin sheets of metal. They are typically pretty short and have a slightly thicker-than-average diameter, as they must be strong enough to keep metal securely in place.

Their tips are sharp and strong, with a self-tapping tip that helps them drill through metal sheets. Their drive is also usually reinforced to prevent cam-out when you’re drilling.

Like drywall screws, sheet metal screws have a fully-threaded shank. However, because they don’t need to be flush with the surfaces they are connecting, sheet metal screws don’t have any beveling or tapering on the bottom part of their head.

Most sheet metal screws have either a pan or rounded head, and they can have pretty much any drive to them.

Machine Screws

These highly specialized screws might look unusual, but their unique design is perfect for their intended use.

The most notable difference between these screws and others is their flat tip. Machine screws are intended to attach two materials together with a nut through a pre-made hole. Because of this, they don’t need a sharp tip to bore through metal or wood.

Machine screws get their name from their original purpose: to clamp machine parts together. However, you can also use them to connect wooden boards or sheets of metal together as long as you have already made a suitably-sized hole.

The threading on a machine screw is unusual due to its uniform and densely-packed threads. If you’re using machine screws, make sure you get the right type of nut, as standard ones won’t fit the threads.

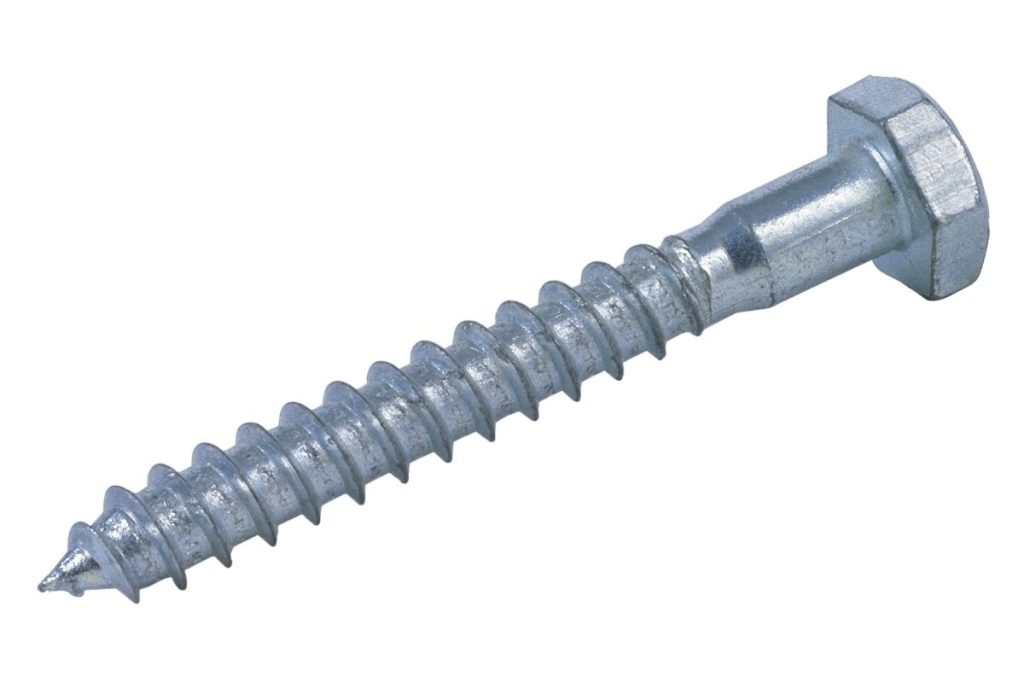

Hex Screws

Also known as Allan screws, Hex screws look more like a bolt than a screw. Their flat tip, hexagonal head, and small threads set them apart from other screws.

However, hex screws still have a drive on their heads that needs a screwdriver.

Hex screws only have a small number of threads on their shanks. These threads are tightly spaced and typically make up less than half of the shank, with the rest being smooth.

You’ll need to bore a hole in advance for your hex screw, and you may need to use a wrench to secure the nut fully.

Because of their thickness and strength, hex screws are great for heavy-duty fastening jobs, both interior, and exterior. They are most commonly used to attach wood to metal or vice versa and are definitely up for the job.

Multi-Purpose Screws

Multi-purpose screws, as their name implies, are versatile types of screws that can be used for all sorts of things. A multi-purpose screw looks very similar to a standard wood screw. However, there are a few differences between them.

While the shank of a wood screw is threaded almost all the way to the top with just a small section that has no threads, a multi-purpose screw is only threaded around halfway. They also have self-tapping tips, making them easier to use in both wood and metal.

And with a beveled head, a multi-purpose screw is designed for countersinking itself as you drive it in for a neat and level finish. Most multi-purpose screws are made of durable stainless steel, making them incredibly tough and resistant to rust and corrosion.

Combine that with the fact that multi-purpose screws typically come with star or square drives, and you’ll never have to worry about snapping or cam-outs.

There are just a few downsides to multi-purpose screws. They tend to be on the pricier side of things and are definitely more expensive than regular wood screws.

Additionally, because they usually come in star and square drives, you won’t be able to use them without the proper tools. That said, multi-purpose screws are well worth the extra cost for the trade-off of their convenience and functionality.

Again, these are just a few of the countless types of screws. While these are some of the most commonly found varieties that you’re most likely to encounter, there are plenty of other types of screws out there with unique and specialized features.

Final Thoughts

So now you know a little more about the many types of screws, the most common varieties, and what they’re used for. We hope you’ve enjoyed looking at these screws and that you’ve learned some handy knowledge about these valuable tools.

Whether you’re preparing for a big woodworking project, stocking up your toolbox, or simply want to learn a bit more about screws, now you know everything you need about the types of screws and when to use them.