Contents

Many builders and designers always opt to use particleboard as an affordable alternative to plywood. While this engineered wood type may not cover all the uses of plywood, it has its benefits. But, to make full use of this type of wood, it is vital to first learn about the types of particleboard available on the market.

Equipping yourself with the right information about different particleboard types allows you to choose the best option for your needs. Here’s a brief but detailed guide on the different types of particleboard available.

What is a Particle Board?

Also known as chipboard, particleboard is engineered wood created by pressing wood chips with synthetic resins and other binders. Typically, the wood chips used to make particle boards come from scraps of lumber products to make particle boards eco-friendly. Compared to plywood, particle boards tend to be denser and uniform. While it is not as tough or neat looking as plywood, it is often used as a substitute, thanks to its affordability.

Types of Particleboard

You can find different types of chipboard on the market. Here are some of the common ones;

Single Layer Particle Board

As the name suggests, single layer particleboard integrates similarly sized wood particles pressed together to form a single flat and dense board. On the outside, the single-layer particleboard is then be covered with veneer or plastic laminate.

The exterior coverings mean that you cannot paint or varnish this type of particleboard. Yet, it remains water-resistant instead of waterproof. Due to this design, single-layer particle boards are ideal only for interior use.

Three-Layer Particle Board

On the other hand, three-layer particleboard features the same materials as single-layer particleboard. However, rather than having a flat, dense board made with wood particles, this single board is then sandwiched between two layers of smaller and dense wood particles.

This means that the outer layers contain more resin than the interior layer. However, unlike single-layer particleboard, three-layer particleboard features a smooth surface and allows for varnishing and painting.

Graded-Density Particle Board

Graded density particle board is also similar to three-layer particle board due to its fabrication design. Both types of particle board are sandwiched by two layers of wood particles. However, their core slightly varies. While three-layer particleboard uses normal wood particles, a graded-density board uses coarse wood particles.

Graded density particle board features a single layer of coarse wood chips sandwiched between two layers of fine wood particles. Due to this stable profile, graded density particle board is ideal for furniture and cabinet making.

Melamine Particle Board

Melamine particle board features décor paper infused with melamine and then integrated into particleboard using a high pressure and heat process. The particleboard used in this process features wax emulsion and melamine urea-formaldehyde resin-bonded wood particles.

Melamine particleboard is scratch-resistant but only water-resistant. Thus, it is not ideal for typical outdoor applications. Instead, it can be used for furniture making, paneling, and wall cladding. These types of chipboard also come in a variety of colors and textures.

Cement-Bonded Particle Board

As the name suggests, cement-bonded particleboard undergoes a magnesium-based cement bonding process. This type of engineered wood features 60% cement, 20% wood shavings and sawdust, and 20% water.

Due to this formula, this type of particleboard is ideal for outdoor use. Cement-bonded particleboard is moisture resistant and doesn’t easily succumb to termites, pests, rotting, or fire. This type of particleboard is popular for making fire-resistant furniture, walls, and false ceilings.

Veneered Particle Board

Veneered particleboard is made using thin slices of wood veneers bound on a particle board surface. The wood veneers used in this type of chipboard come from actual wood, such as teak or mahogany. Compared to regular particleboard, these types tend to be more resistant to warping.

Additionally, veneered particle boards tend to have smooth and neat surfaces, making them perfect for decorative items. To give designers and builders more variety, veneered particle boards come in a variety of color options. This type of engineered particleboard wood is ideal for cabinet doors, shelving, and partitioning. Additionally, veneered particleboard allows you to use power tools such as trim routers to create neat designs.

Laminated Particle Board

Laminated particleboard is made by adding a laminate sheet to the surface of the particleboard. Laminate particleboard stands out from regular particleboard thanks to its improved aesthetics and long-lasting durability. Yet, it still remains to be quite an affordable option compared to plywood or natural wood.

Uses of Particleboard

Particleboards offer multiple uses based on the type you go for. After all, this engineered wood type tends to be cheaper making it readily available on the market. Here are some of the common applications:

Furniture Making

Along with engineered wood options such as plywood and MDF, particleboard is also a popularly used variety. Veneered particleboard is a popular option for making furniture due to its attractive, neat, smooth, and durable exterior. These types of particleboards also come in different color options to further widen the creative opportunities.

You can also find veneered particle boards used in bathrooms, kitchen countertops, and cabinets. But, this is not to say that regular particleboards aren’t used for furniture making. This type of particleboard is also used for various furniture pieces, including beds, wardrobes, bookshelves, shoe racks, and even TV stands. Due to its relative flexibility and ease of use, you can create a range of decorative pieces using particleboard.

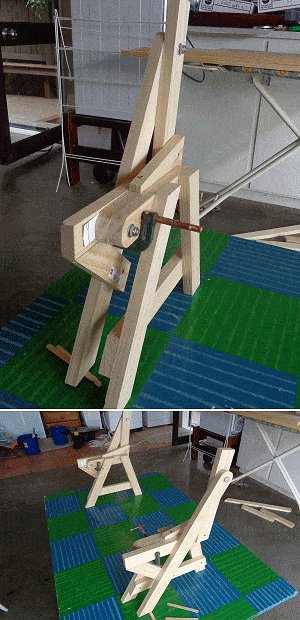

Routing in Wood Working

In addition to the color and finish options, you can also use several power tools to beautify your furniture. For example, due to the stable and smooth surface of particleboard, you use routers fitted with carbide router bits to improve the edging of your furniture.

However, this is not all you can do with particleboard. In fact, due to this flat, stable profile and consistent core, particleboard is used by several manufacturers to create decorative panels and cabinet doors. You will find many routed panels and cabinet doors for insertion into wood products made using particleboard.

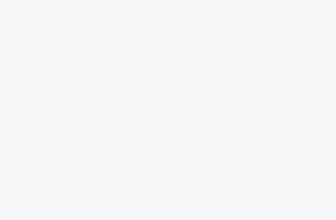

Doors

Particleboards are typically designed with strong, stable, and consistent cores. It is this very same design that makes it a perfect material for door core material. Thus, particle boards are a popular wood option for flush and solid doors. Particleboard is typically bound to the door’s skin while its solid core does a better job at gilding the screws. This means that particleboard also offers more reliable support for door hinges.

Temporary and Protective Flooring

Particleboard features a much denser and solid design which makes it great for temporary flooring structures. In most cases, it is used as covering and additional protection for hardwood floors. Typically, laminated particleboard is used due to its attractive surface finish.