Contents

How to build a Narrow Shed

Introduction

Similar articles: Tudor style shed | Board & batten shed

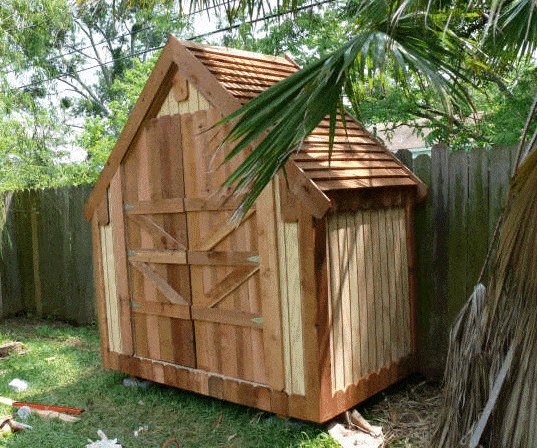

This narrow shed is suitable for the smaller backyard or garden or for those that do not want to use more area than necessary.

With a footprint (ground area) of 2100mm (7ft) wide by only 1200mm (4ft) deep this shed could be considered compact but you will be amazed just how much will go into it.

4 x 7 narrow garden shed

$5.00- Pay online by credit card, debit card, or Paypal using Secure Server Paypal. You do not need a Paypal account if paying by credit or …

|

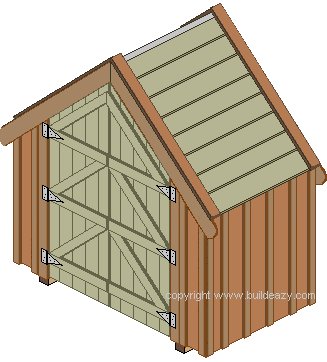

The shed stands 2600mm (8′ – 8″) high at the apex and tapers down to 1400mm (4′ – 8′) high at the sides.

Double doors make for an easy access into the whole of the inside area allowing the shed to be fully utilized.

The narrow shed is very strong. It is constructed out of 100×50 (2×4) framing lumber, vertical board-and-batten siding and overlapping board roof. The floor is plywood on 100×50 (2×4) floor joists that sit on skids thus making the shed ‘relocatable’.

The Parts List

Note 1: All dimensions are in both metric and imperial. Measurements are given first in millimeters followed by ft and/or inches in brackets.

Note 2: The size (width and thickness) of the lumber referred to in the ‘Parts List’ below is the nominal size. Because most framing lumber is dressed or seasoned the actual size of the lumber will be less than the nominal size.

For example: 100×50 (2×4) lumber when dressed or seasoned will have an actual size of approximately 90×45 (1 1/2″x 3 1/2″).

The measurements given in all the plans in this project are the ‘actual sizes’.

| Part ID/Size | For | Amount and Lengths | Comments |

| Floor and Sub-floor | |||

| [a] Skids 100×100 (4×4) | Under floor | 2 pieces 1200mm (48″) | Treated |

| [b] Joists 100×50 (2×4) | Floor frame | 6 pieces 2010mm (81″) | Treated |

| [c] End joists 100×50 (2×4) | Floor frame | 2 pieces 1200 (48″) | Treated |

| [e] Floor panel 18mm (3/4″) plywood | Floor | 1 piece 2100×1200 (4ft x 7ft) | Cut from standard 2400×1200 (4ft x 8ft) sht |

| Frame: Wall and Roof | |||

| [f] Bottom plates 100×50 (2×4) | Front/rear walls | 2 pieces 2100mm (84″) | |

| Side walls | 2 pieces 1020mm (41″) | ||

| [g] Top plates 100×50 (2×4) | Side walls | 2 pieces 1020mm (41″) | |

| [h] Studs 100×50 (2×4) | Side walls | 6 pieces 1175mm (47 5/8″) | |

| Front wall | 2 pieces 1200mm (48″) 2 pieces 1500 (60″) | Cut 45° angle one end of all front wall studs | |

| Rear wall | 2 pieces 1200mm (48″) 2 pieces 1500 (60″) 2 pieces 1950 (78″) | Cut 45° angle one end of all rear wall studs | |

| [i] Trimmer studs 100×50 (2×4) | Front wall | 2 pieces 1480 (59 3/4″) | Cut 45° angle one end of both trimmer studs |

| [j] Apex block 100×50 (2×4) | Rear wall | 1 piece 300 (12″) | Cut to suit |

| [k] Blocking 100×50 (2×4) | All walls | Cut to suit. Approximately 14m (46ft) altogether. | |

| [l] Raking Top Plate 100×50 (2×4) | 4 pieces 1530mm (61 3/16″) | Front and rear walls | Cut 45° angle both ends |

| [m] Raking header 100×50 (2×4) | Front wall | 2 pieces 1040mm (41 5/8″) | Cut 45° angle both ends |

| [n] Ridge blocking 100×50 (2×4) | Ridge | Cut to suit. Approximately 1000mm (40″) altogether. | |

| [o] Brace blocking 100×50 (2×4) | Rear and side walls | Cut to suit. Approximately 5.5m (18ft) altogether. | |

| [p] Galvanized metal strap ties | Tie raking top plates together | 2 pieces 300mm (12″) | |

| [z] Rafters 100×50 (2×4) | Roof | 2 pieces 1485mm (59 3/8″) | Cut 45° angle both ends |

| Exterior Cover: Siding and Roof | |||

| [q] Building wrap / Builders felt | Wrap frame | 15 sq meters (160 sq ft) | |

| [r] Vertical board 250×25 (1×10) | Siding | 36 meters (120 ft) altogether | |

| [s] Vertical batten 75×25 (1×3) | Siding | 36 meters (120 ft) altogether | |

| [t] Trim 100×25 (1×4) | Exterior corners and around door opening | 10.5 meters (35ft) altogether | |

| [u] Roof sheathing 12mm (1/2″ plywood) | Roof | 2 pieces 1500mm x 1200mm (4ft x 5ft) | |

| [v] Roof boards 250×25 (1×10) | Roof cover | 16 pieces 1200mm (48″) | |

| [w] Galvanized V shaped ridge flashing | Roof ridge | 1 piece 1200mm (48″) | |

| [x] Barge board 150×25 (1×6) | Gables | 4 pieces 1800mm (72″) | |

| [y] Barge cap 100×25 (1×4) | Cables | 4 pieces 1800mm (72″) | |

| Door | |||

| [d1] Slats 150×25 (1×6) tongue and groove | Door | 10 pieces 2250mm (90″) | |

| [d2] Brace 100×25 (1×4) | Door bracing | 9.5 meters (32ft) | |

| [d3] Astragal 50×25 (1×2) | Door | 1 piece 2250mm (90″) | |

| [d4] Stop 50×25 (1×2) | Door stop | 5 meters (17ft) | |

| [d5] Hinges 150mm (6″) “T” hinges | Doors | 6 of |

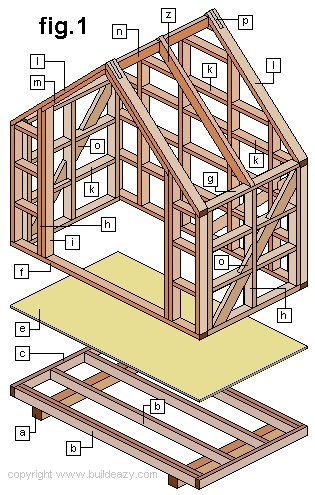

The floor, roof and stud layout plans

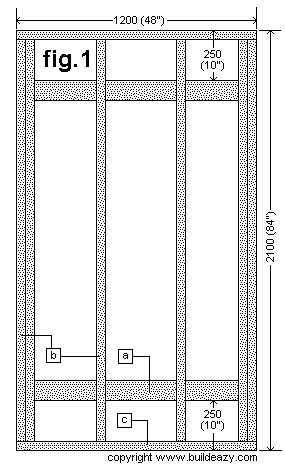

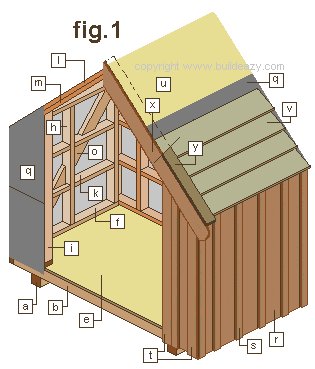

Fig.1 – Floor layout

The floor layout plan below gives the overall dimensions of the floor frame.

The floor frame is constructed of 100×100 (4×4) skids [a] and 100×50 (2×4) joists [b] and end joists [c].

All floor frame lumber should be treated or otherwise suitable for exterior use.

Individual member lengths are given in the Parts List.

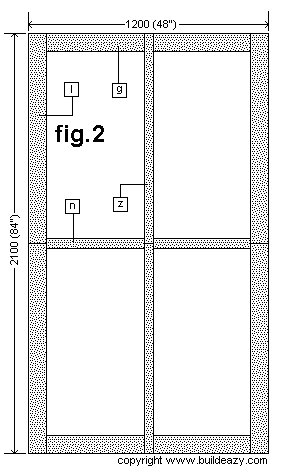

Fig.2 – Roof layout

The shed roof layout plan below gives a birds-eye view of the roof frame layout.

The members shown in the roof frame plan are the side wall top plates [g], the front and rear wall raking top plates [l], the middle rafters [z] and the ridge blocking [n].

All the members in the roof frame are 100×50 (2×4) stock.

Individual member lengths are given in the Parts List and drawings showing individual member lengths and angle cuts are in the Front and Roof plans.

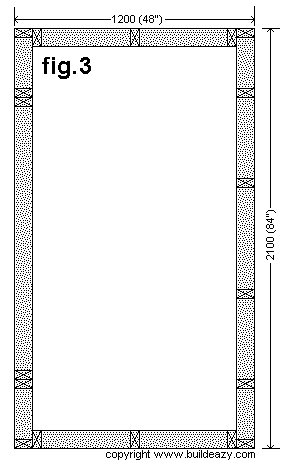

Fig.3 – Stud layout

The shed stud layout plan gives a birds-eye view of the wall stud layout.

More detail, placement measurements as well as individual member lengths and angle cuts are shown in the Front and Roof plans, and the Rear and Side plans.

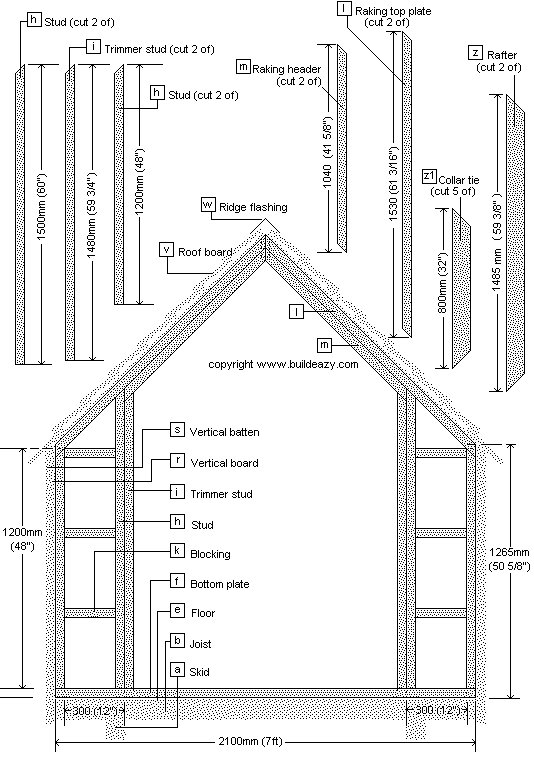

Front frame plan

This drawing shows the front wall frame with all necessary dimensions. There are also drawings of individual wall frame members and roof rafter members showing angle cuts and lengths.

All frame lumber is 100×50 (4×2) stock and all angle cuts are 45°.

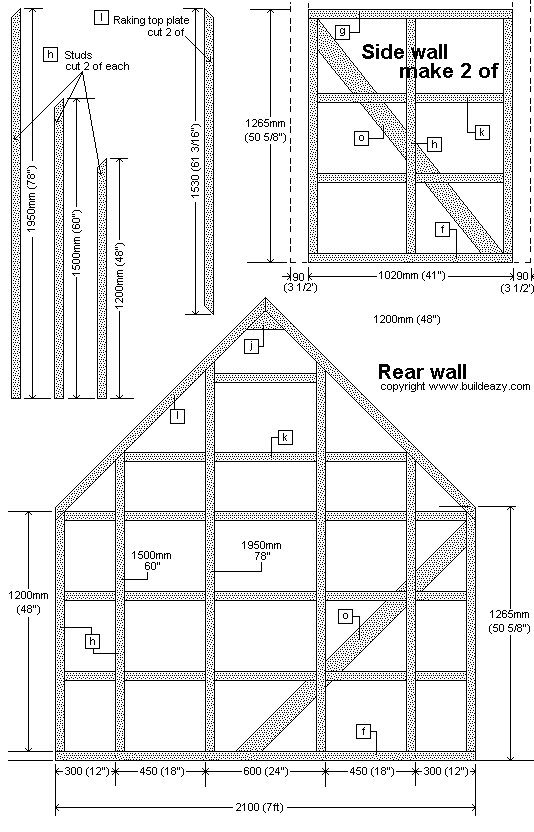

Rear and side frame plans

This drawing shows the rear and side wall frames with all necessary dimensions. There are also drawings of individual wall frame members showing angle cuts and lengths.

All frame lumber is 100×50 (4×2) stock and all angle cuts are 45°.

Instructions

Step 1. Familiarize yourself

- Skim through all the pages first to get an understanding of the project.

- The parts list with part identification number (ID) and individual stock size and length is in the Introduction and Parts List.

Note: All dimensions are given in both metric and imperial. Measurements are given first in millimeters followed by ft and/or inches in brackets.

Step 2. The Floor

- Cut the Floor Frame members consisting of 100×100 (4×4) skids [a], 100×50 (2×4) joists [b] and 100×50 (2×4) end joists [c].

- Make up the floor frame on level ground. Refer to the Parts List and floor layout plan for individual member lengths and the floor layout. Use 90mm (3 1/2″) galvanized nails for the floor frame and ‘toenail’ the joists to the skids.

- Cover the floor with 18mm (3/4) inch treated plywood [e], nailing a maximum of 200mm (8″) apart around the perimeter and along all joists using 60mm (2 1/2″) galvanized nails.

Step 3. The Wall Frames

- All the lumber used in the wall frames is 100×50 (2×4) stock however, the actual size of the stock when seasoned and dressed or surfaced is more likely to be 90×45 (1 1/2″x 2 1/2). The plans reflect the actual size.

- Make up the front, rear and two side wall frames using 90mm (3 1/2″) galvanized nails.

- Refer to the front wall plan and the rear and side walls plan for individual member lengths and wall layout.

- Tie the opposing raking top plates [l] together with galvanized metal strap ties [p] (see fig.1).

- Once the frames are made, squared and braced, lift them upright onto the floor and nail them together at the corners. Ensure the bottom plates are straight and flush with the outer edge of the floor. Next nail the bottom plates to the floor using 90mm (3 1/2″) galvanized nails. Nail all along the bottom plates except in the door opening. Cut that piece out with a handsaw.

- Because the wall frames were made and braced square and the floor is level, the frames will automatically be plumb (vertical).

Step 4. The Roof Frame

- Cut two rafters [z] to the dimensions as shown in the front and roof plan.

- Nail the two rafters [z] together at the top and also at the bottom to the top plates [z] ensuring that the rafters are centralized between the front and rear walls.

- Check that the rafters [z] and the raking top plates [l] on both front and rear walls are all parallel to one another and then measure, cut and fix in place the ridge blocking [n] between the top of the rafters and the tops of the front and rear walls as shown in the above picture.

Step 5.The Roof Sheathing

- Cover the roof area with 12mm (1/2″) plywood so that the plywood is flush with the top of the rafters, the outside edge of the side walls and the outside edge of the front and rear walls. Nail a maximum of 200 (8″) apart along the ridge blocking [n], the rafters [z], the raking top plates [l] and the side wall top plates [g] using 50mm (2″) galvanized nails.

Instructions continued

Step 6. The Wrap / Felt

- Cover the roof and walls with a building wrap or builders felt [q] and make it taut and waterproof before fixing the vertical boards and roof boards.

- Hold the wrap/felt in place with staples or small flathead nails.

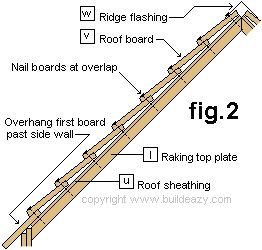

Step 7. The Roof Boards

- Cut 16 lengths of 250×25 (1×10) roof boards [v] at 1200mm (4ft) long.

- Start on one side of the roof. Have the first (lower) board overhang the side wall by half of its width and nail it in place. See fig.2 below.

- Nail the roof boards [v] through the sheathing [u] into the rafters [z] and raking top plates [l] with 90mm (3 1/2″) galvanized nails. Work upwards overlapping each board by 50mm (2″). Nail thru the boards where they overlap. See fig.2.

- Do the same to the other side of the roof.

Step 8. The vertical boards

- On the side walls cut the vertical boards at a length long enough to tuck under the lower overhanging roof board [v] and run below the floor joists.

- On the font and rear walls cut the vertical boards at a length long enough to be flush with the top of the raking roof and run below the floor joists. The tops of the boards will need to be cut on a 45° angle to match the rake of the roof.

- Fix the 250×25 (1×10) vertical boards [r] to the wall frames beginning at the corners.

- Nail all vertical boards [r] to the horizontal blocking [k] with 60mm (2 1/2″) galvanized nails spaced approximately 75mm (3″) apart including the nail that will be going thru the Batten. Leave a gap about the width of a nail shank between each board.

Step 9. The roof flashing, rake board and rake cap

- Cap the top roof boards with a piece of L-shaped galvanized flashing [w] running the length of the ridge. Ideally the ridge flashing should be wide enough to cover at least 100mm (4″) along each plane (side) of the roof. (See fig.2)

- Cut 4 lengths of 150×25 (1×6) rake board [x] at 1800mm (6ft) long.

- Make a 45° angle cut at one end and make a round cut at the other end on all 4 boards.

- Fix the rake boards [x] to the tops of the vertical boards [r] at both front and rear gables. Ensure the top edges of the rake boards are flush with the top of the roof boards [v].

- Add the 100×25 (1×4) rake cap [y]. Miter the top end of each length of rake cap at a 45° angle. The rake cap sits on top of the rake board [x] and covers the ends of the roof boards [v].

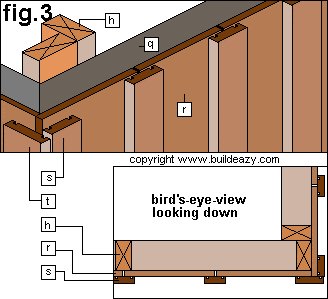

Step 10. The vertical battens and trim

- Fix the 75×25 (1×3) vertical battens [s] over each vertical board join. Preferably, the battens should have a groove each side of the join to stop water being drawn in by capillary action

- Nail on the center line of the vertical batten, through the gap between the vertical boards and into the blocking. Overlap battens on each corner using 75×25 (1×3) batten on one side of each corner and 100×25 (1×4) trim on the other side.

- Using one length of 100×25 (1×4) stock and one length of 75×25 (1×3) stock at each corner will give a balanced look. (see fig.3).

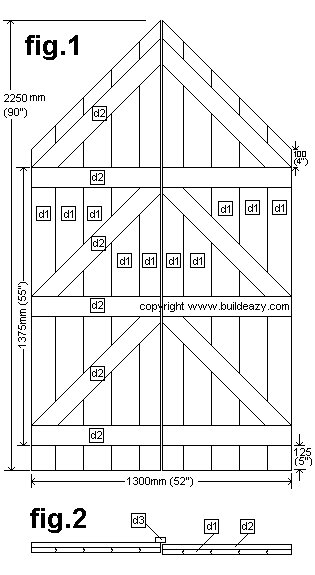

Making a Door

It is more common than not when making a shed door to fix the bracing on the inside. However, by fixing the bracing to the outside of the door does have its advantages.

1.) It makes for a neater door stop finish. The door stop is the molding that is fixed to the wall frame or jamb around the inside perimeter of the door/s covering the gap between the door edge and the wall frame/jamb thus stopping or limiting draught or rain.

2.) It makes for a neater astragal finish. The astragal is the molding that covers the gap between a pair of doors when closed. The astragal is fixed vertically to the back of the outer edge on one of the doors. It also stops or limits draughts and rain.

Also… Hinging the doors to the surrounding trim (door casing) allows for the doors to be able to open 180°.

The door lumber

- Use 150×25 (1×6) tongue-and-groove lumber for the vertical door slats and 100×25 (1×4) for the door bracing.

- Use a lumber suitable for exterior applications such as cedar or treated pine.

Making the door – Instructions

Step one.

- Cut 10 T&G (tongue-and-groove) door slats [d1] 2250mm (90″) long.

Step two.

- On an even surface join five slats [d1] together with the face (best side) up forming a rectangular panel.

- The width of the rectangular panel will be wider than the required door width at this stage.

Step three.

- Cut three pieces of 100×25 (1×4) horizontal braces [d2] the same width as the rectangular panel, arrange them in their right places and screw them to the door slates. Refer to fig.1 for the placement of the horizontal braces.

- Use wood screws suitable for exterior use and of a length just slightly less that the thickness of the brace and slat combined.

Step four.

- Turn the rectangular panel over. Measure and mark the required door width central on the panel and cut off (rip down) the excess each side.

Step five.

- Cut off the top 45° corner.

Step six.

- Turn the panel over. Measure, mark, cut and screw in place the three 100×25 (1×4) angled braces [d2].

- Door one is finished.

Step seven.

- Make a second door the same as the first by repeating steps two-thru-six and use fig.1 for reference.

Note: Make the second door a mirror image of the first, that means that the top 45° corner on the second door will be opposite to that of the first.

- Use the fig.1 dimensions as a guide only. The exact door measurements should be taken from the door opening (rough opening) in the wall frame once the shed shell (frame, siding, roof) is complete. Allow 6mm (1/4″) gap between the door and frame all the way around and between the two doors.

Step eight.

- Add the hinges to the horizontal braces on the doors and then ‘hang’ the doors in place by fastening the loose ends of the hinges to the trim surrounding the door opening (see picture at the top of the page).

Step nine.

- Fix 50×25 (1×2) molding (door stop) to the jamb around the inside perimeter of the door/s to cover the gap between the door edge and the jamb.

Note: Do not fix the door stop tight against the door on the hinged edges. A little bit of play is needed to ensure the edge of the door does not bind against the door sto when the door is being opened or closed.

Step ten.

- Fix a length of 50×25 (1×2) wood [d3] (the astragal) vertically to the back of the outer edge on one of the doors. (see fig.2)

I would just like to says thanks for the help. Your site is great it helped find the perfect storage solution for my small backyard. Your site gave me great info on where to start and what to do as this is the first building I’ve ever built. You may use the following photo (if you wish) to show a finished product.

Bill Griffin, Groves, TX.

Picture at the top is very stylish but different from what the plans will give. Looks like it was sided with and door made with fence pickets? Also no rake cap?