Introduction & description

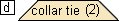

This medium-size wishing well stands approximately 1400mm (4′-8″) high and 600mm (2ft) wide. It is a cross between a small planter and a full-size wishing well, and can be used either as a planter box or a garden ornament. This wishing well is a lot of fun to build.

The lumber used in this project is pressure-treated board. You can use a different type of wood as long as it is suitable for exterior use. For the most part, 100mm x 25mm (1×4) stock is used, the exception being the roof boards which are 150mm x 25mm (1×6), and the spindle and spindle handle which are 25mm x 25mm (1×1).

Wishing Well Plans

$5.00

|

The measurements are given in both millimetres and inches. The millimetres are given first followed by inches in brackets. For example: 100mm x 25mm (1×4).

The metric measurements are not an exact match to their imperial equivalents for rounding off purposes, so use one or the other.

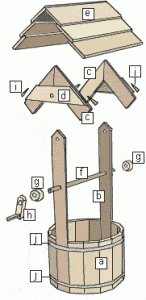

Schematics and materials

Schematics

What you will need

Note: All lumber should be pressure-treated or suitable for exterior use.

• 12 meters (40ft) of 100mm x 25mm (1×4) board;

• 5 meters (17ft) of 150mm x 25mm (1×6) board;

• 1 meter (39″) of 25mm x 25mm (1×1) wood;

• 4 meters (13.5ft) of 30mm (1 1/4″) galvanized metal strap;

• 26 exterior type 50mm (2″) long screws;

• 16 exterior type 75mm (3″) long screws for the roof boards;

• two 10mm (3/8″) galvanized bolts 60mm (2 1/2″) long, and

• around 70 of 25mm (1″) galvanized flathead nails.

Alternatives: The 150mm x 25mm (1×6) board for the roof can be replaced with 100mm x 25mm (1×4) board. If so, make adjustments when working out the lumber quantities.

Also, the roof boards do not have to overlap, as shown in the plan – they can be butted up (made flush) to each other. It really boils down to taste.

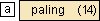

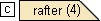

The cutting list

14 pieces of 100mm x 25mm (1×4) lumber @ 400mm (16″) long. The palings and the extended palings form the wishing well wall.

2 pieces of 100mm x 25mm (1×4) lumber @ 1200mm (4ft) long overall, with a 45 degree point at one end. The extended palings continue up from the wall and support the roof.

4 pieces of 100mm x 25mm (1×4) lumber @ 400mm (16″) long, cut back one end at a 45 degree angle.

2 pieces of 100mm x 25mm (1×4) lumber @ 400mm (16″) long, cut back both ends at a 45 degree angle .

6 pieces of 150mm x 25mm (1×6) lumber @ 700mm (28″) long.

1 piece 25mm x 25mm (1×1) lumber @ 1000mm (39″) long. Cut both the spindle and handle from this piece.

2 pieces 100mm x 25mm (1×4) @ 100mm (4″) long with a 35mm (1 3/8″) hole in the center of both pieces. These pieces can be cut from off-cuts and are used as washers on the spindle. They can be left square or rounded.

1 piece 50×25 (1×2) @ 180mm (7″) long with a 35mm (1 3/8″) hole at each end. This piece fits on the spindle and takes the handle. It can be made from off-cuts.

4 wedges 0 to 20mm (0 to 3/4″) thick and 120mm (5″) long. These can be cut from off-cuts and are fixed to the topside ends of the rafters.

4m (13.5ft) of 30mm (1 1/4″) galvanized strap or similar.

Note: If this strap is not available in your location other options include galvanized water heater restraining strap, or even galvanized wire fixed with appropriate staples.

FYI, palings (in the context of this content) are the upright (vertical) members of the wishing well wall.

The plans

Instructions – Steps 1 to 2

Step 1. Cut all the members

- Cut out all the members (pieces) to the dimensions as shown in The cutting list, on page 3.

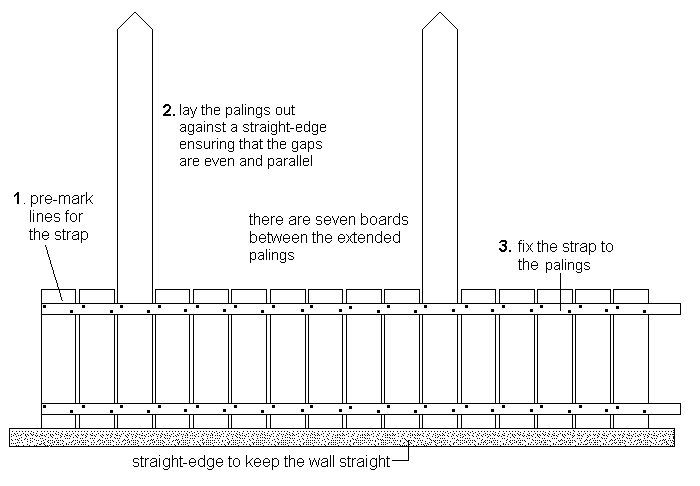

Step 2. Mark and lay out the palings

- Measure 40mm (1 1/2″) down from the top and the same amount up from the bottom of all 14 palings (a) and mark a line.

- Also mark corresponding lines on the 2 extended palings (b), making a total of 16 marked boards altogether.

- Lay all the palings (a) and extended palings (b) next to one another on an even surface, with the bottoms against a straight edge to keep them in line.

- When laying down, ensure that there are 7 palings (a) in between the 2 extended palings (b). (See diagram below.)

Note: The gap measurements are given on the next page.

Instructions – Steps 3

Step 3. Space the palings

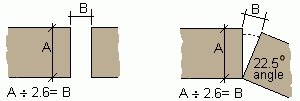

- The distance of the gap between the palings is crucial to forming a good circle. In this instance, the palings are 25mm (1″) thick so the gap will be 10mm (3/8″). If the palings are a different thickness, then the gaps will also need to be different. (See The Gap Equation on the next page for a detailed explanation.)

- If you use palings of a different thickness, use the Gap Equation on the next page to establish the gap size. That is, divide the thickness of the paling by 2.6

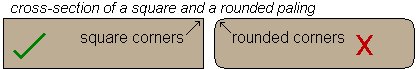

Note: This gap formula will only work if the corners of the palings are square. If the corners are rounded the equation will not work.

- There is however, another method that does work. There is a way you can use lumber with rounded corners, as explained on page 8.

The gap Equation

- The distance of the gap between the palings is crucial to forming a good circle. The gap, or spacing between the palings (a) should be the thickness of the wall board divided by 2.6.

For example: The thickness of the palings in this project is 25mm (1″).

Therefore: 25mm (1″) divided by 2.6 = 9.6mm or near enough to 10mm (3/8″). Hence the gap or spacings between the palings in this project will be 10mm (3/8″).

Note: The width of the wall paling has no bearing on the size of the gap. Whether the palings are 100mm x 25mm (1×4) or 200×25 (1×8), the gap will be the same. Only the thickness and the total number of palings matter. 14 palings (a) and 2 extended palings (b) make 16 palings in all. Each paling is at a 22.5 degree angle to the next, and 22.5 degrees times 16 is 360 degrees, which is a circle. Get it? Yep!

Note: The above formula will only work if the corners of the boards are square. If the corners are rounded the equation will not work.

But, there is a way you can use lumber with rounded corners, as explained on the next page.

The gap for lumber with rounded corners

- The equation to find the gap needed between the palings (to form a circle) is easy enough to work out if the lumber used has square corners.

However, sometimes lumber has slightly rounded corners, and that is a horse of a different color.

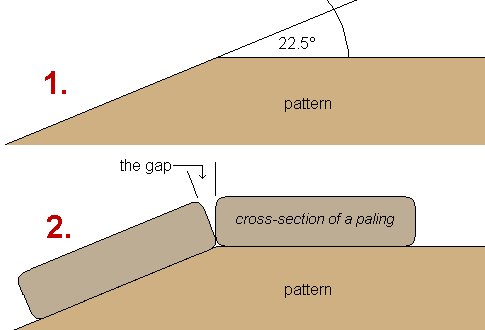

You must measure the gap when two palings are together, as if they were fixed in place on the wall.

That scenario can be emulated by using a pattern as described below. - The wall of this wishing well is not really a circle as such, it is a 16 sided polygon called a hexadecagon. Actually, a regular hexadecagon because all the sides are the same.

- So! make a pattern (as below) depicting two adjacent sides of a regular hexadecagon (16 sided polygon).

Then butt the edges of two paling pieces together at the vertex (where the angle changes).

The gap (at the top) between the two pieces is the gap that all of the palings will need to be spaced when making up the wall.

1. Using a piece of board or plywood or just about anything, cut an angle along one edge running 22.5 degrees off the edge line, as shown in fig.1 above. That is the pattern.

2. Using two off-cuts of paling, butt them together where the angle changes on the pattern, as shown in fig.2 above. The gap (at the top) between the two pieces of paling is the gap you will need to space all of the wall board pieces to form the circle for the wall.

Instructions – Steps 4 to 5

Step 4. Fixing the metal strap and forming the circle

- Now that the science lesson is over, and the 14 palings (a) and 2 extended palings (b) are all lying in place on even surface with correct gaps, the 2 metal straps (j)can be nailed to the palings using two 30mm (1 1/4″) galvanized flathead nails at each meeting. Place the straps 40mm (1 1/2″) down from the top of the palings and 40mm (1 1/2″) up from the bottom.

- See the drawing on page 5 for layout.

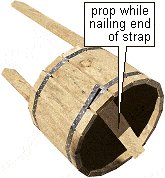

- When the metal straps are nailed in place, flip the structure over and commence rolling it up. If the gaps between the palings are correct, it will form an accurate circle. Overlap the metal straps by 1 paling and nail off. Use a prop to hold everything rigid while nailing the end of the strap.

Step 5. The roof

- On a flat surface, make up the two roof frames by first screwing the rafters (c) together at the apex, then screwing the collar ties (d) to the rafters (c). Then nail the wedges (i) to the bottom topside of each rafter. See fig 1 below.

- Next, sit the two roof frames upright on top of the two the extended palings (b) and clamp in place. Drill a 10mm (3/8″) hole through the collar tie (d) and the extended wall board (b) and fasten together using one 10mm (3/8″) galvanized bolt 60mm (2 1/2″) long for each roof frame. See fig 2 below.

- Screw the roof board (e) to the rafters (c), beginning with the lower roof board (e) overhanging the rafters (c)by about 20mm (3/4″). Then fix the other roof boards (e) in place, ensuring that they are evenly spaced. See fig 3 below.

Final instructions – Step 6

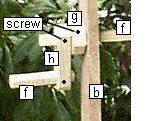

Step 6. The handle and spindle

- Drill two holes in the extended palings (b) 800mm (31″) up from the bottom. Make the hole size 35mm (1 3/8″) or big enough so that the spindle (f) can easily go through it. We have chosen treated 25mm x 25mm (1×1) square timber for the spindle because it is more readily available and easier to obtain than treated doweling (round rod).

- Make up two wooden washers (g), by drilling 35mm (1 3/8″) holes in the center of blocks made up from two pieces of off-cuts 100x100mm x 25mmmm thick (4″x4″x1″thick). The outside edge of the washer can be rounded or just left square-shaped.

- In a similar fashion make up the handle arm (h). Drill a 35mm (1 3/8″) hole each end of a 50×25 (1×2) @ 180mm (7″) long piece of lumber.

- Now put it together. Thread the spindle (f) through the holes in the extended palings (b). Slide a washer (g)on at each end about 5mm (1/4″) away from the extended palings (b) and then put a screw through each washer (g) fastening it to the spindle (f).

- Next, slide the handle arm (h) along the spindle (f) until it is against a washer (g), and fasten to the spindle (f) with a screw. Cut off excess spindle (f) and use this as the handle which will also be fastened in the handle arm (h) with a screw.

Note. No floor

This wishing well is sturdy enough to not require a floor. It can be used just as a garden ornament, planters can be placed inside it, or it can be placed over an existing plant.

Don’t forget to throw a 5 cent coin in and make a wish!

Mmmmmm – Better make that 10 cents. Inflation you know.

Here is a photo of the wishing well I made this July 2016. I used pressure treated deck lumber. I’m not very handy with wood , but after promising my Wife a wishing well I finally had to do something after putting her off for 16 years. I found this quite easy to make and didn’t cost a lot of money . My Wife loves it.

The buildeazy plans were easy to follow .

Robert Almond

Here is a photo of the wishing well my brother Jim built this summer 2016.

He is a better woodworker than I am.

He refined his a little but still stuck to the buildeazy plans.

He didn’t have any plans to follow for the small bucket and just made it as he went along. Looks good.

Robert Almond

Good afternoon. My name is Fernando, I am Brazilian.

I did the wood well.

The attached photos of my work.

Thank you.

Fernando Oliveira

I built this wishing well using your plans using macrocarpa wood.

Best wishes

Hello

I love your web site, My hobby is wood work and I was asked to make a wishing well for a friend�s wedding.

Your patterns were very helpful.

The large one ended up in my garden as the wife took it. Picture attached

The other 2 were used in separate weddings, both brides were very grateful.

Bob Schultz

I revised the wishing well plans slightly to a smaller size to make a wishing well for my daughter’s wedding.

I also put in a bottom panel and an acrylic top. Later turned into a mid-sized planter.

Scott Laird

From John O’Hanley

Attached are pictures of two wishing wells that I built from your plans.

These were 6th grade auction projects at my sons’ Catholic school.

Each student ‘inked’ a wish on a trim-board and also painted a small wooden emblem to be glued to the roof.

Chad

Thank you for your website! The wishing well is just the first of many projects I plan to build from your plans.

Debbie Espey

Thanks for the idea and free plans. Heres one from Florence SC.

Ben J

Wishing well

C.J.

Here is my finished Wishing Well, I followed your plans, with a few alterations. I used treated lumber, the plans were easy to follow and I already have some requests from family and friends for more.

I enjoyed this project and will probably be doing more from your web site.

Jerry Troute Thanks

Wishing Well for Mom’s 60th Birthday.

Thank you very much for the plans. I absolutely loved making them. I modified them to use my Kreg Jig where I could, and also used 1 nails on the strapping.

Thanks again, Angie B, Southern Ca

I built the well out of treated pine fence plank material; 5/8″ thick by 6″ wide. I ripped some of the planks to 4″, and calculated the gap to be about 1/4″. At first, the metal strapping I used was too thick; plus, the short nails I had to use pulled out of the wood. Also, the holes in the strapping were too large, and the wood pieces wouldn’t stay centered. I switched to “plumber’s tape” – thinner metal strapping – and wood screws, which were self-centering. I maintained the gap by using a bunch of carpenter’s pencils, which happened to be the right width.

When I put it together, the thin planks plus the thin metal strapping made it sort of flimsy, so I took a couple of old, rusty barrel rings; cut them and overlapped the material so that it was against the inside of the circle of planks, and pop-riveted it to that dimension. Then, I screwed it to the planks in 4 places. I put these rings at the top and bottom. (You can see the top ring in photo #2.)

Since the well doesn’t have a bottom, and I was worried about it possibly blowing over in our Central Texas breezes, I put an “X” of boards just above the bottom barrel ring (see photo #2), and screwed it to the sides. I’ll put some rocks on those boards to make sure it stays upright.

Here’s a couple of pictures of the finished article. Joe M.

Dear build easy,

I love your site . This was a really fun project for me. I am by no means a carpenter and the plans worked great. I finished it with a coat of oil based regal red.

The small trellises I found at big lots store in Tempe Arizona and the bucket at Wal-Mart.

I put this together for my very special lady friend to celebrate a 2 year anniversary of our meeting.

She loves it. As you can see in the background it goes nice with a little wheel barrel I built from wood. Thanks for the effort you put into your website.

Sincerely

Scott Redfern

Tempe Arizona

This is my wishing well I built from your free patterns. My friends and co-workers like it very much.

I put ornamental cabbages an pumpkins in for a fall theme. You have a great web site.

I will be building more from your plans in the future.

Mitch Webster

Hello

I just finished the medium-size wishing well.

I made it from White spruce.

I’m from Quebec and that wood is very cheap here, but I wouldn’t recommend that wood for any other projects.

Since was my first ever wood building, I used cheap wood, the whole wishing well cost 10$ with screws.

I’m planning to redo it later, but with white pine for a better look.

Thank you for free plans, very good plan with detailed information, since my English is not perfect, I love images with length and angles.

Jonathan

Wishingwells I made from buildeazy free plans. I made them from recycled old fence material.

Thank you buildeazy!

Jeff

| would like to take time to thank you for your web site excellent, I started and finished my first project today, the wishing well,very happy with the results. I have a photo attached

Regards,

Declan&Jackie from Galway, Ireland

Thank you for your wishing well plan. I proposed to my wife at a wishing well and since then she’s always wanted one for the garden. Well I didn’t know that but on our 12th anniversary I got the idea to make one, found your site and made it.

I live in Papua New Guinea, and pine is not widely available here. Neither is the galvanized metal strap. But, Kwila (a very hard wood) is, as is hooping iron. The hooping iron is used in the construction of roofs here. It’s about 1/16 inches thick, and it’s about 1 inch wide. Needless to say, it was stronger metal, galvanized, and harder wood.

I had to pre-drill a lot.

ALSO the wood here is not measured in inches and feet, it’s all in millimeters and cut thus. So I had to make a few changes to your plan to get the right amount of wood, but, because you included the math on the “barrel” portion, I was able to figure it out very easily.

Here is the final results, this picture is taken in my back yard in Papua New Guinea.

Chad

Big thanks to your free online plans. It took me a long time to make both of these projects. In the end,it’ll be worth it big time.

wishing well:

I followed the directions accordingly and the results are what you see. The only extra touch I gave it was adding shingles to the roofing for a better fashionable look. I must say,I like what I see and i believe I did an incredibly good job! The only issue i can see from my mistake was making the gap between the boards 3/8 (which is what the directions called for if the boards is 1″ thick) which i should have made it smaller cause the metal straps look loose all the way around. If i can’t sell my wishing wells,they’ll look great in my front yard! either way,i can’t luck out You guys are awesome for posting up the plans. Much thanks here in northern Ohio,USA.

Adirondack chairs:

these baby’s are a major hit in my local area! I haven’t even finished making all 4 and people are already considering them sold! Personally,I’m really starting to enjoy these Adirondack chairs. The only problem i had was taking 1 1/2″ off the arms cause i thought they were too long. Wanted to shorten them up a bit. I should have never done that. Other than that,these chairs look and feel terrific! Once I’m done making them for other people,I’m gona make one for my own darn self for a change. Big thanks for your free online plans guys. Much thanks here in northern Ohio,USA. Thanks.

Adam, northern Ohio,USA.

I built the wishing well from your plans for a friend as a thank you for befriending my Grandmother while she was in the nursing home. My friend was with my Grandmother when she passed away in December. The wishing well brought tears of joy and sadness. Thanks for the plan!! What a wonderful way to say thank you to a dear friend!

Lee

Just wanted to take a moment to say thank you for the Wishing Well plans. It had taken just under 5 hours to complete with the help of my 13 year old Daughter. Once we completed it we stood back and looked at our finished product with pride. Must say the wife was equally impressed. Thanks again.

Mike Wuelfrath Sarasota, Florida

My husband used your free wishing well plan and amended the size to 36″ so it would hide our well pump. We painted it to match our house and we love it! People are asking him to make one for them.

Thank you!

Barb Zonitch

Hi, i really enjoyed constructing this project, great easy step by step instructions.

I built this well using left over treated pine decking boards (90 x 22 mm) , changed the roof a little, otherwise as per plans…cheers great site!!!!!

Colin

I LOVE my wishing well! Hubby made it for me for Mother’s Day and it’s perfect; he said it was very easy and easily adapted. (He made the base a few inches taller to completely hide the well pipe that I hated having to look at.) Here’s a photo; I plan to sit flowers on the cover of the pipe and voila! It’s a planter!

Julie K., McKean PA

With a few minor alterations here is my completed well! I made the handle useable by using a wooden closet dowel.

Later I put a plaster plant pot lined with pond fabric to make this well a water fountain. Looks great! THANKS!!!!

Kari White

Thank you so much for the free wishing well plans.

The cost of buying or hiring a wishing well was astronomical. We also like to make things ourselves and the gifts (bonbonniere) to our friends and our bridal party we made ourselves, including the bridesmaids’ jewellery and a friend of the family made the table decorations. So you could say our wedding was mostly ‘hand made’.

So we made our wishing well together and tucked it in the corner of the reception venue, so our guests could just post well wishes into the false top (cardboard box cut into a circle with a slit in it).

We finished it with an outdoor stain and it now sits pride of place in our garden along with the memories of building it together and our wedding day.

Thanks again

Claire and Stephen Kent

Point Cook, Australia

Hello, Here’s a picture of the well I made for my mother’s back yard, Using Build Eazy plans !!

Thank you for your help

Nahuel Uria Ushuaia, Tierra del Fuego, Argentina

Hi, I love your site and really appreciate your plans. I would really love to see the photos the people have posted, but no matter which browser I use they won’t display. How can I see them?

Here’s my well that I made from these plans. I used pressure treated wood and applied a solid color wood stain. I used a piece of metal roofing that matches the house. I plan to make a matching wooden bucket to put in it to fill with flowers in the summer.